Aluminum alloy laser welding technology and its application

Aluminum alloy has the advantages of light material, corrosion resistance, low temperature resistance, and good mechanical properties. It is widely used in many industrial manufacturing fields such as aerospace, rail transportation, automobiles, ships, and chemicals. In recent years, with the country’s macroeconomic system reforms on environmental protection, energy conservation, and emission reduction, there has been a great demand for aluminum alloy materials, especially high-strength aluminum alloy materials with high rigidity, high corrosion resistance, excellent processability, and high mechanical properties. It has gradually become an indispensable important material for lightweight applications in various manufacturing industries. At present, the main welding methods for aluminum alloys are TIG welding, MIG welding, stir friction […]

Effective application of laser welding technology in automobile manufacturing

Laser welding technology has the characteristics of high welding process efficiency and good flexibility. In the automobile manufacturing process, it can be used for the welding of automobile bodies and the welding of various automobile parts, reducing the overall weight of the automobile body, improving the accuracy of body assembly, and meeting the needs of lightweight automobile manufacturing. Quantify and improve the demand for safety performance, while also reducing assembly costs and stamping costs in automobile manufacturing and improving the integration of the body. Laser welding technology principles Laser welding is essentially a fusion welding technology that uses laser beam as the main energy source to complete the welding work […]

Portable laser welding machine buying guide

Power and Laser Type The power of the laser is one of the most important factors to consider. Higher power lasers can weld thicker materials but are more expensive. Common power options are: You’ll also need to choose between pulsed or continuous wave (CW) lasers. Pulsed lasers are better for thin sheet metal while CW lasers are required for thicker workpieces. Portability and Design Since these are handheld units, portability is key. Look for compact and lightweight designs that are easy to maneuver. The welding gun should have an ergonomic grip and be well-balanced. Some models come with a rolling cart for easy mobility. Ease of Use User-friendly controls and […]

Application of laser technology in aviation machining

With the rapid development of the aerospace industry, higher requirements have been placed on the processing technology of aerospace engine parts. Traditional mechanical cutting has been unable to meet the needs for processing accuracy and processing efficiency. As a non-contact processing technology, laser processing has the advantages of high processing precision, small heat-affected zone, high processing efficiency, and high degree of automation. It shows great application prospects in the precision processing of key components of aerospace engines. Laser processing technology can achieve precision processing of complex three-dimensional structures that are difficult to achieve with traditional mechanical processing, greatly improving the overall performance of aircraft engine components. Application of laser technology […]

Control System of Laser Cutting Machine for Profiles

Special-shaped materials, such as square tubes, rectangular tubes, oval tubes, flat tubes, U-shaped tubes, channel steels, I-beams, etc., are widely used in the furniture industry, display shelves, etc. due to their beautiful appearance, good strength and mechanical properties. Fitness equipment, sheet metal processing, decorative advertising, kitchenware and bathroom, household appliances, agricultural and forestry machinery and other fields. These pipes usually need to be connected accordingly to form a variety of entities. The connection between two or more pipes is called pipe intersection in drawing geometry and engineering drawing, and the curve formed at the intersection is called intersection. Wire. Where pipes intersect, holes need to be drilled into the pipes, […]

Application and development of laser welding technology

Laser welding is a non-contact welding process that uses laser energy to join together several different welding materials and then select them into a whole to meet the different requirements of different parts for material properties. Laser welding only applies vertical pressure at the welding point, thereby minimizing the mechanical stress on the product and achieving lightweight equipment with the lightest weight, optimal structure and best performance to ensure welding quality. Advantages of laser welding Laser welding machines use the characteristics of high directivity and high power density of laser beams to focus the laser beam in a small area through an optical system to form a local high temperature, […]

Unlimited guide of laser welding machine

How Does a Laser Welding Machine Work? A laser welding machine works by focusing a concentrated beam of light, known as a laser, onto the surface of materials to be joined. This intense heat generates a localized melting zone, allowing the materials to fuse together seamlessly. The process typically involves directing the laser beam through a series of mirrors and lenses to precisely target the welding area. Key components of a laser welding machine include: Laser Source: The device that produces the high-energy beam of light, often using technologies like fiber lasers, CO2 lasers, or solid-state lasers. Optics System: Consists of mirrors and lenses that manipulate and direct the laser […]

The unlimited guide of laser cutting machine

What Are Laser Cutting Machines? Laser cutting machines are tools used in various industries for precision cutting and designing projects. They emit a high-powered laser beam to either cleanly cut or etch a specific design on materials such as steel, plastic, or wood. The beam can either burn, vaporize, or melt away the excess product, leaving a superior finished design or edge. These machines are often used in engineering for the precision cutting of components of machines and in industrial applications for cutting structural and piping materials and flat sheet material such as metal. They have settings known as computer numerical control (CNC), which control and direct the laser beam’s […]

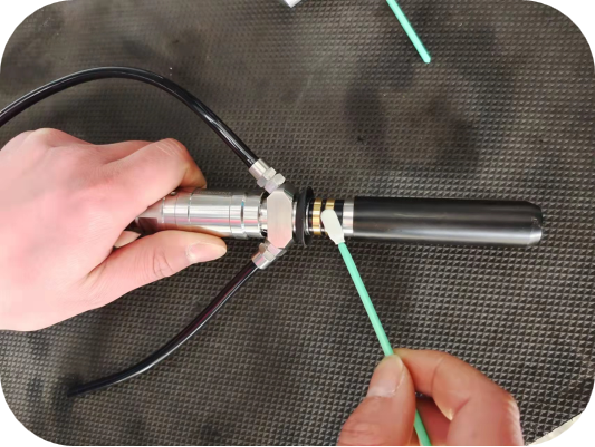

JQ CE welding machine installation instruction

Equipment installation process Host location installation Equipment installation conditions The distance between the side of the equipment and the wall is ≥0.5m, and the distance between the equipment exhaust fan and the wall is ≥1m. The operating environment of the equipment is within 0~45℃ Low humidity and relatively dry (humidity within 20%~80%, no condensation) Less dust, dust, disgust, water and other places No flammability, corrosive gas or liquid Will not receive too much impact or vibration Stay away from electromagnetic fields (TIG welding equipment, etc.) Stay away from strong magnetic fields Add water to chiller Water quality requirements:Circulating water allowed to be used by the chiller: purified water, distilled water, […]

Introduction to Tube and Plate Laser Cutting Machines

The development and widespread adoption of tube and plate laser cutting machines mark a significant technological advancement in the field of manufacturing and fabrication. These machines, embodying the latest in laser technology, have revolutionized the way industries approach material cutting, offering an unmatched blend of precision, efficiency, and versatility. This introduction delves into the intricate details of these machines, exploring their capabilities, applications, and the technological nuances that set them apart. 1. The Core Mechanism: Tube and plate laser cutting machines operate using a high-powered laser beam, which is precisely focused to a minuscule point. This intense concentration of energy serves to melt, burn, or vaporize the material it encounters. […]