What Makes Fiber Lasers Special and Expensive Compared to CO2 Lasers?

Introduction to Fiber Lasers Fiber lasers represent a significant advancement in laser technology, distinguished by their unique design and operational principles. A fiber laser uses an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, or dysprosium as its active gain medium. The design of fiber lasers allows for a high degree of beam quality and energy efficiency. The light generated in the fiber core is amplified and channeled through a flexible fiber optic cable, allowing for greater control and precision. The compact nature of fiber lasers, combined with their high electrical-to-optical efficiency, makes them a preferred choice in industries that demand high precision and efficiency. Fiber lasers […]

Methods to Extend the Service Life of Laser Tube Cutting Machines: A Comprehensive Guide Focused on FLT-6035ETN

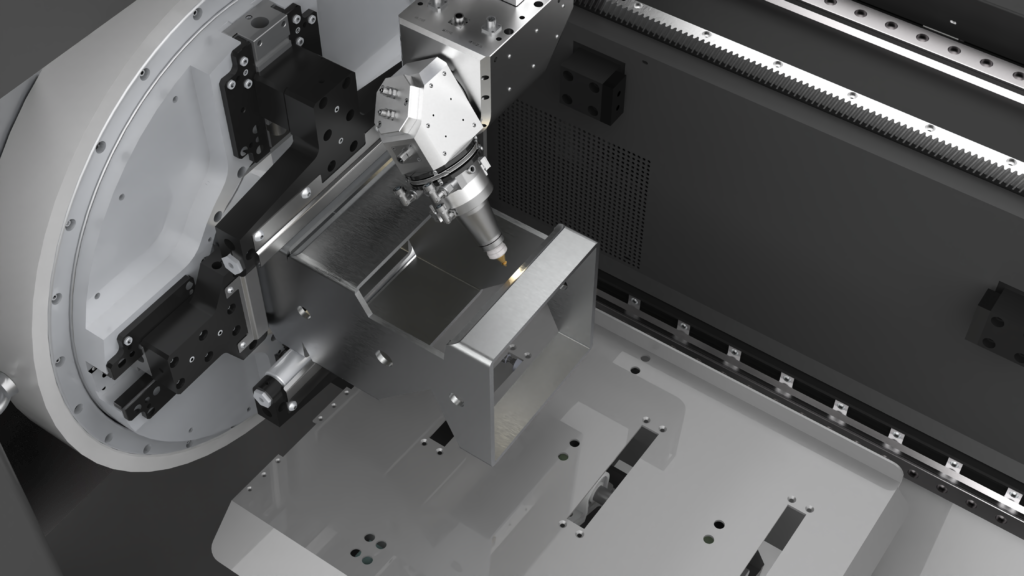

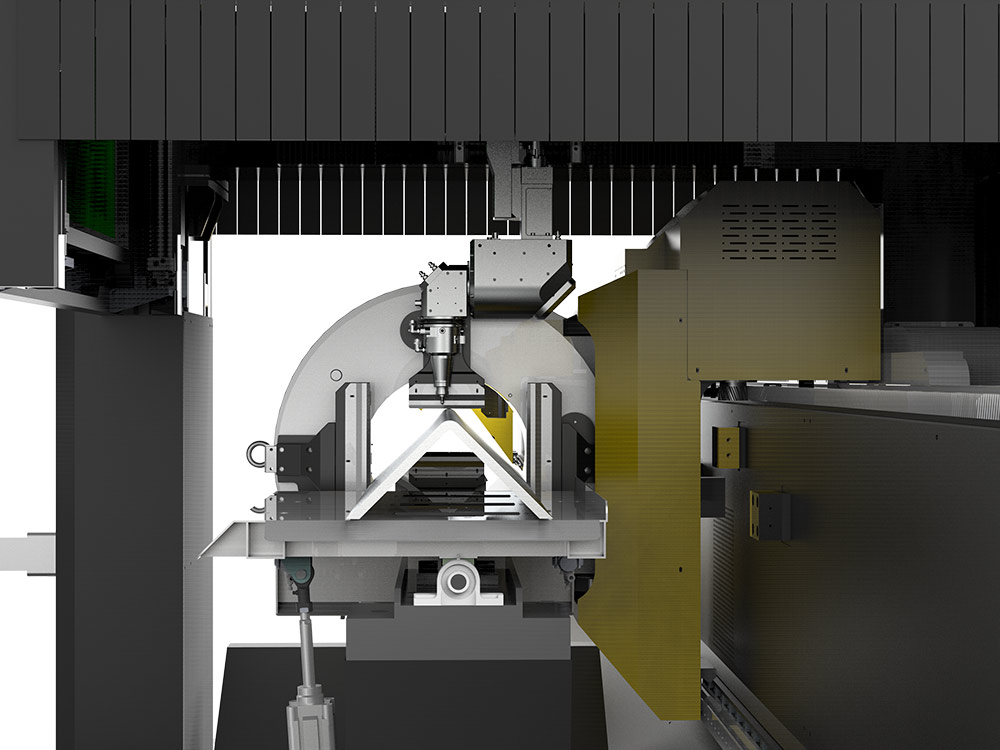

Methods to Extend the Service Life of Laser Tube Cutting Machines: A Comprehensive Guide Focused on FLT-6035ETN Introduction The integration of advanced laser tube cutting machines like the FLT-6035ETN into modern manufacturing processes marks a significant technological advancement. These machines epitomize precision, efficiency, and versatility in metal fabrication. However, their sophisticated nature necessitates a strategic approach to maintenance and operation to maximize their lifespan and maintain their high performance. Understanding the mechanics, features, and proper care of the FLT-6035ETN is essential for any operator or maintenance team tasked with its upkeep. Overview of FLT-6035ETN The FLT-6035ETN stands out in the world of laser cutting with its unique features and capabilities, […]

Methods to extend the service life of industrial welding machine lasers

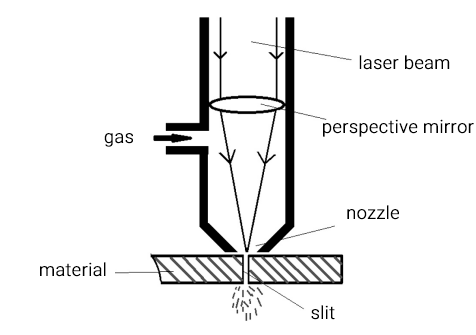

The reason why welding machine lasers are easily damaged. The laser cutting process uses high-power and high-density laser beams to scan the surface of the workpiece and locally heat the material to thousands or even tens of thousands of degrees Celsius in a very short time, so that the irradiated material can quickly vaporize and melt. , ablate or reach the ignition point at the same time, the molten material is blown away by the high-speed airflow coaxial with the beam, so as to cut the workpiece and achieve the purpose of cutting the material. At present, the purity of compressed air in large domestic steel plants often cannot meet […]

Application of laser cutting technology in machinery manufacturing

Main types of laser cutting technology Vaporization cutting Vaporization cutting is the most widely used cutting form in laser cutting technology. The laser power density used in this cutting technology is high. Once the laser is irradiated on the mechanical workpiece, except for a few Part of it will be reflected, and most of it will be successfully absorbed and converted into heat energy, causing the surface of the workpiece to reach the boiling temperature in a short time and forming a keychain on its surface. In addition, due to surface oxidation and other effects, the absorption rate will be greatly increased, and the ejected steam will effectively take away […]

Analysis on the application of laser in modern manufacturing technology

The essence of laser cutting technology is to form a laser beam by focusing high energy to directly melt or vaporize the workpiece to be processed. At the same time, the melt or oxide is processed under the action of auxiliary gas to complete the entire cutting operation. Laser cutting technology is a very advanced mechanical manufacturing and processing technology, which plays a very important role in improving the core competitiveness and overall level of machinery manufacturing enterprises. 1 Characteristics of laser processing Laser processing was originally developed and proposed by Germany in the 1960s. Its working principle is to use lasers to form high-energy particles to directly melt or […]

Stainless steel laser cutting process optimization and surface quality research

Most items made of stainless steel are anti-corrosive, and items made of stainless steel are also processable. Therefore, stainless steel can be used in different fields, such as the aerospace industry, the medical industry, and different types of mechanical instruments. Industry, stainless steel materials are also widely used in coal mine machinery and facilities, and it is very important to choose the appropriate cutting processing method. It is difficult to guarantee the cutting quality and cutting efficiency when cutting materials with traditional cutting technology, but laser cutting technology It can make up for the shortcomings of traditional cutting technology. Laser cutting technology has the advantages of high speed and high […]

Research on the application of laser processing technology in agricultural machinery manufacturing

Application of laser cutting technology in agricultural machinery manufacturing Laser cutting technology applies a laser beam to the surface that needs to be processed for processing. At this time, a very high temperature will be formed on the surface to complete the processing. After the application of the laser beam, the oxidation reaction can be achieved. The steam and slag generated at this time can be directly discharged into the external space through the auxiliary gas, and then various shapes and sizes that meet the user’s requirements can be formed on the surface of the workpiece. In this way The entire processing process can be completed. In addition, laser cutting […]

Laser cutting follow-up control system

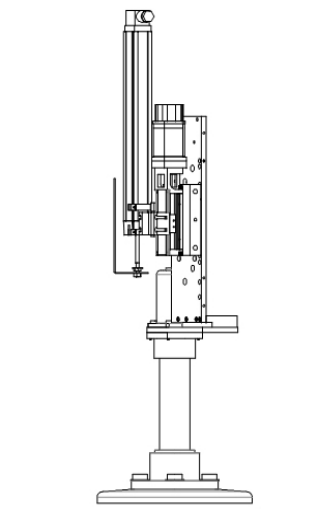

The laser cutting servo control system is a mechanical device based on motion control and capacitive sensing, including four parts: controller, capacitance detection chip, capacitance sensor, servo motor, objective lens driving mechanism and input device. The working principle is to treat the laser nozzle and the metal cutting plate as a flat capacitor, and quickly detect the capacitance value of the flat capacitor according to the detection system to adjust the distance between the laser nozzle and the plate to achieve the purpose of dynamically controlling the focal length to be constant. Keywords: laser cutting technology; follow-up control; constant focus. With the vigorous development of the manufacturing industry, traditional cutting […]

Application of laser processing technology in the manufacturing of transmission tower

Principles, characteristics and advantages of laser processing technology 1. 1 Principle of laser processing technology Laser processing is a very important high-energy beam processing method, which has the characteristics of strong laser directionality, high brightness, good monochromaticity, and good coherence. The principle of laser processing technology is that the laser light emitted by the laser generator is converted and focused by the lens to obtain a highly parallel columnar or strip-shaped beam. The extremely high energy density is obtained and concentrated into a small area on the processing material. After absorbing the energy of laser irradiation, the material heats up rapidly in a very short time and undergoes a series […]

Research status and application of laser processing technology in marine engineering

Application of laser cutting technology in marine engineering There is a huge demand for metal cutting in the field of marine engineering. The traditional metal cutting technologies are high-speed oxygen-flame cutting technology and plasma arc cutting technology. However, both of them have shortcomings such as slow cutting speed, large thermal deformation of the workpiece, and difficulty in ensuring product accuracy. As competition in the offshore engineering market becomes increasingly fierce and industry profits continue to decline, customers are becoming more and more strict on quality. Traditional metal cutting technology is unable to meet market demand and is gradually being eliminated by the market. The characteristics of laser determine that laser […]