Research on the application of laser processing technology in machinery manufacturing

Laser drilling Laser drilling is an important part of laser processing technology and an important link in processing workpieces. Common drilling types include fastening holes, positioning holes, etc. The quality of the holes has an important impact on the performance of the workpiece. Compared with mechanical processing, the application of laser drilling technology can improve the drilling effect, making the hole wall smoother and more rounded. In addition, compared with other processing technologies, laser drilling technology is more intelligent. In the initial stage of drilling, the hole depth and hole diameter increase greatly, but as the processing time increases, the hole depth and hole diameter increase slower. The reason for […]

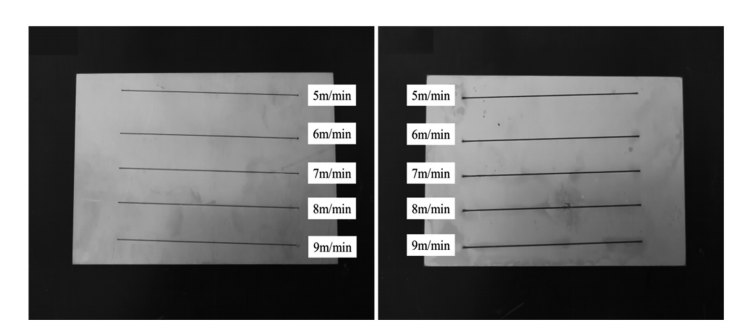

Research on laser cutting process of thin stainless steel plates

Effect of cutting gas pressure on cutting quality When laser cutting, different cutting gases are selected according to the material of the cutting plate. Nitrogen is mainly used to cut stainless steel. The selection of cutting gas and its pressure has a great impact on the quality of laser cutting. The main functions of cutting gas include: supporting combustion and dissipating heat, promptly blowing off molten stains produced by cutting, preventing molten stains from rebounding upward into the nozzle, protecting the focusing lens, etc. The experiment adopts the controlled variable method, the cutting speed is set to 8m/min, the focus position of the laser focus is -0.5mm, and the air […]

Research on laser cutting head focus control technology

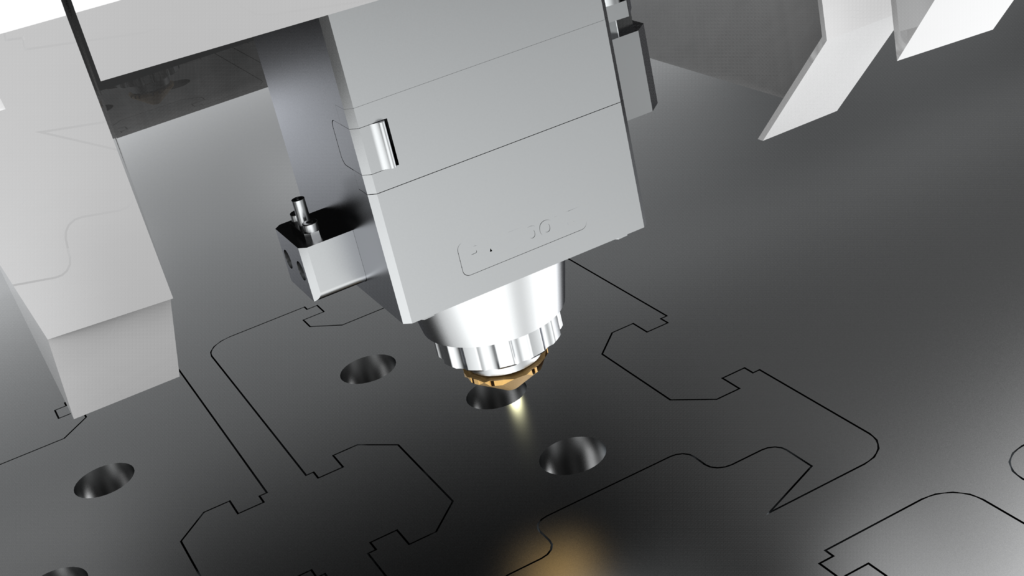

The main components of the cutting head are laser cutting technology, which is a non-contact processing technology using laser as energy. It is widely used in metal cutting, automobile manufacturing, aerospace and other fields with its own advantages. The laser cutting head is a key component of the laser cutting machine. Taking the fiber cutting head as an example, its main components include fiber connection module, collimation module, focusing module, protective window module, non-contact sensor, cutting nozzle, etc. The optical fiber is connected to the cutting head from the connection module interface. The collimation module converges the divergent laser into a parallel beam, and finally focuses it into a light […]

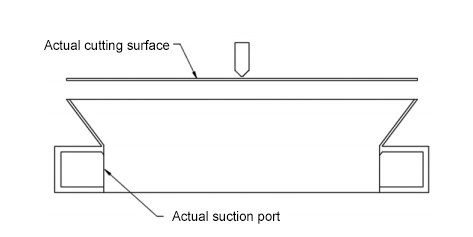

Research and Optimization of Dust Removal and Smoke Exhaust System for Laser Cutting Machines

Laser Cutting Smoke Hazards and Smoke Exhaust Mechanism Laser Cutting Smoke Hazards The smoke released when laser cutting metal plates can be roughly divided into dust and aerosols. 97% of them have a diameter of less than 5.7 μm, which means that most of the smoke can be Inhaled into the body. Depending on the cutting material and scene, other harmful substances will be produced, such as oil on the surface of the board, and very complex hydrocarbon composite gases; for example, if the surface of the board is filmed, aliphatic and olefin compounds will be released during cutting, accompanied by Distinctive odor. If the smoke and dust generated by […]

Basic principles and influencing factors of laser cutting

Laser cutting principle Laser is the product of stimulated radiation. Its production is inseparable from three key elements: working material, pump and resonant cavity. After absorbing energy, low-energy level particles will transition to high-energy level orbits, but the state of high-energy level particles is unstable and will Falling to a low-energy orbit and emitting photons at any time, laser light is generated when many particles emit photons with high consistency at the same time. Laser processing can be divided into hot processing and cold processing according to the size of photon energy. Cold processing is generally used in the laser marking process of plastic parts. The laser completes the separation […]

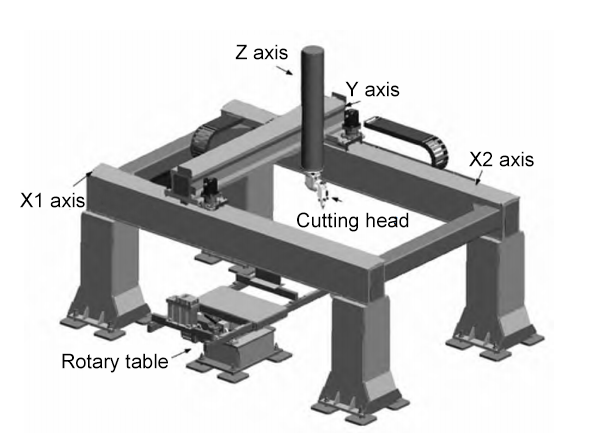

Introduction to the composition of three-dimensional five-axis CNC laser cutting machine

The development of fiber laser technology and the reduction of costs have greatly promoted the application of fiber laser in metal sheet cutting. For example, as the requirements for lightweight automobiles continue to increase, the demand for laser cutting of three-dimensional sheet metal covering parts and structural parts has gradually increased. The thickest plates among structural parts such as passenger car body panels and beams are usually within 3mm, and the product structure is complex and changes rapidly. Ordinary robot-type 3D laser cutting machines cannot fully meet the requirements of related processes in terms of accuracy, stability, efficiency, etc. and quality requirements, at this time the advantages of the three-dimensional […]

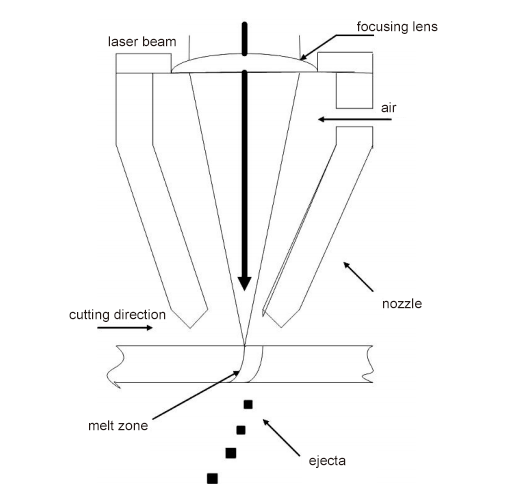

Laser cutting mechanism and evaluation index

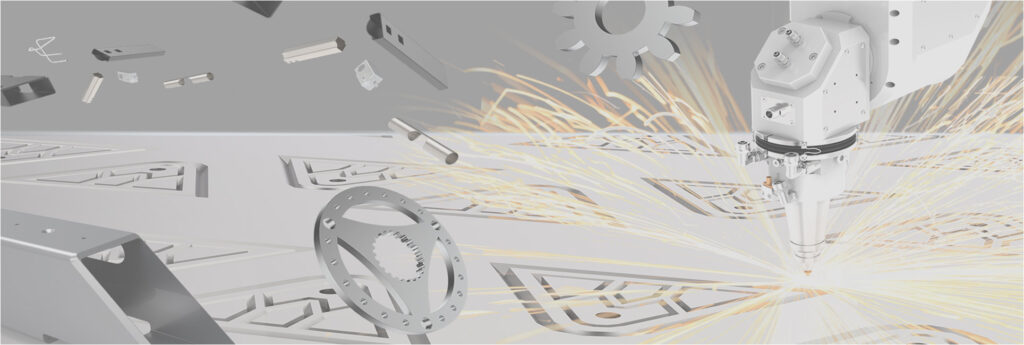

Principle of laser cutting Laser cutting is to focus the laser beam into a small spot, causing it to act on the material. The laser power density can reach more than 106 W/cm2. Under such high power density laser irradiation Under the action, the metal material quickly vaporizes and evaporates, forming holes. The molten metal residue is blown away by the high-pressure gas blown out coaxially, forming a cutting slit. The cutting head moves under a pre-designed program to cut the corresponding shape. In laser cutting, oxygen is used as an auxiliary gas, which is beneficial to the cutting of certain metal sheets. At high temperatures, oxygen will undergo an […]

Application of high-power laser cutting technology

Laser cutting principle Laser cutting uses a focused high-power, high-energy-density laser beam to irradiate onto the plate to be processed, causing the irradiated material to quickly melt, vaporize, ablate or reach the ignition point. The high-speed airflow blows away the molten material and cuts the sheet. Precautions during the production process of laser cutting equipment Equipment procurement There are many domestic laser equipment manufacturers, but there are not many leading companies that master key technologies. The purchase of large equipment must go through various forms of research, investigation and consultation. Laser power is the main factor that determines work efficiency and the ability to cut plate thickness. Therefore, laser power […]

Design of a flexible production line system for plate laser cutting

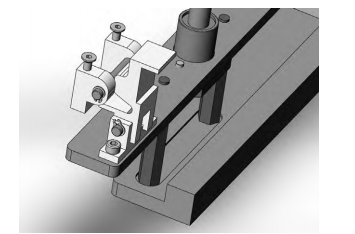

In order to improve the consistency and yield rate of products after laser cutting, it is necessary to accurately position the plates that are loaded during cutting. However, because wooden boards have a certain degree of elasticity and have large dimensional errors and are easily deformed, and the boards are stacked at random positions in the loading bin, pre-positioning is required before processing and clamping to ensure the positioning accuracy of the right-angle origin of the square boards ( (Reduce the error between workpiece coordinates and processing coordinates) and then use the robot suction cup to grab and transport it to the laser cutting machine processing area. After the loading […]

Common faults and solutions of CNC laser cutting machines

Overview of CNC laser cutting machine Laser cutting machine consists of CNC system, external optical path system, water cooling machine, cutting system and laser. When the laser cutting machine is working, it uses energy to cut metal materials, non-metal materials, composite materials, and organic materials. Laser cutting technology has many advantages, such as fast processing speed, no heating of materials, non-metallic materials will not be deformed due to heat, and higher work efficiency during processing. Common faults and solutions of CNC laser cutting machines 1 CNC laser output failure The first is that the air tightness of the air path at the laser output is reduced. Due to the reduction […]