Laser cutting technology application research on titanium alloy forgings

In the forging industry, laser cutting technology has been widely used in the flash and skin of structural steel and stainless steel forgings, while laser cutting technology on titanium alloy forgings is still a banned or restricted process in China. However, with the rapid development of laser cutting equipment, the improvement of laser equipment power and the diversification of laser cutting atmosphere have provided basic support for the high-quality application of laser cutting titanium alloy forgings. Therefore, the application research of laser cutting technology on titanium alloy forgings is more meaningful. Application research on laser cutting of titanium alloy under 3000W power and O2-assisted conditions The macro morphology of the […]

Basic principles and influencing factors of laser cutting

1 Principle of Laser Cutting Laser is the product of stimulated radiation. Its production is inseparable from three key elements: working material, pump and resonant cavity. After absorbing energy, low-energy level particles will transition to high-energy level orbits, but the state of high-energy level particles is It is unstable and will fall to a low energy level orbit at any time and emit photons. Laser is generated when many particles emit photons with high consistency at the same time. Laser processing can be divided into hot processing and cold processing according to the size of photon energy. Cold processing is generally used in the laser marking process of plastic parts. […]

Research status of laser cutting technology

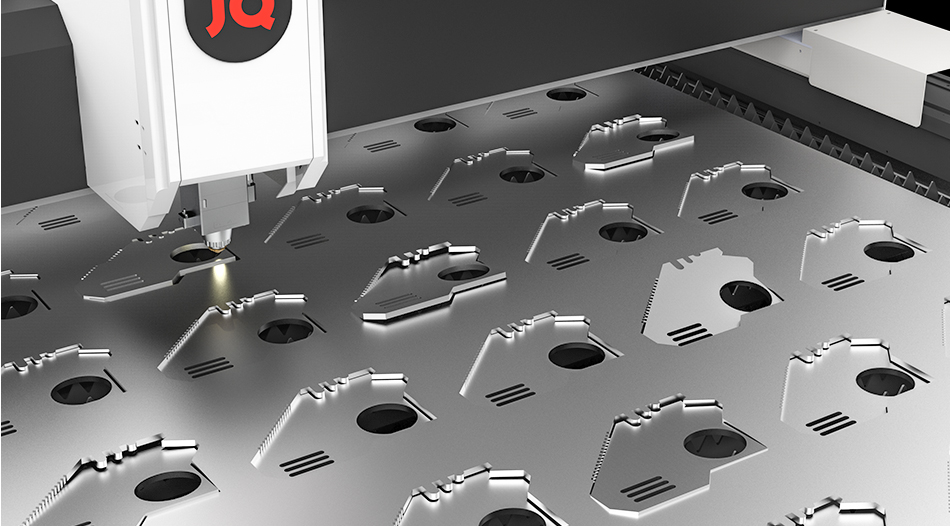

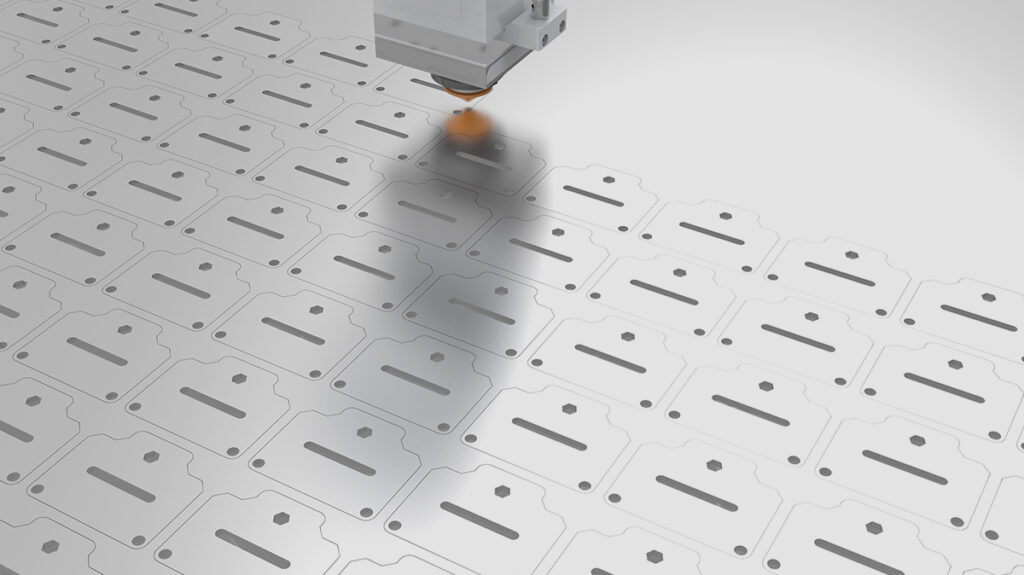

Laser cutting technology is a cutting technology that uses laser to process planes. It has attracted the attention of many scholars due to its advantages such as high processing precision and no pollution. With the continuous development and progress of science and technology, people have put forward higher requirements for the performance of parts, so the methods and equipment for processing parts are constantly updated and improved. Most traditional parts are made by mechanical processing methods. Mechanical processing has shortcomings such as low processing efficiency and poor environmental friendliness. Laser processing just solves these problems. Laser cutting technology uses a laser generator to output a high-energy-density laser beam. The laser […]

Process optimization of hydraulic support structural parts based on laser cutting

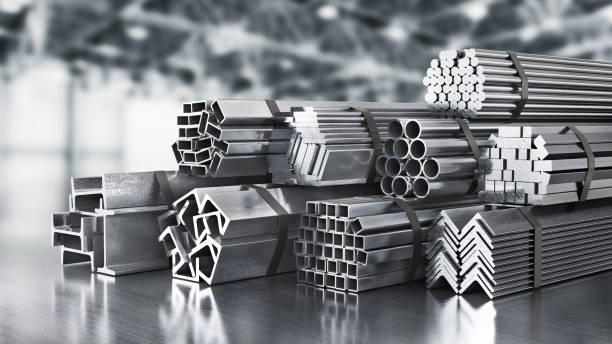

The main part of the hydraulic support is composed of structural parts of medium-thick steel plates and oil cylinders. As shown in Figure 1, the structural parts composed of medium-thick steel plates account for about 79% of the total weight of the hydraulic support. The raw materials are mainly medium-thick steel plates with a thickness of 16 mm ~ 50 mm. For the cutting of medium-thick steel plates, the traditional cutting equipment is mainly flame cutting machines and plasma cutting machines. To a certain extent, plasma and flame cutting equipment are prone to uneven shrinkage and a certain degree of thermal deformation when cutting and blanking, and kerf compensation is […]

Laser ring cutting and hole making process for laminated aluminum alloy sheets

Among laser cutting methods, there are four main cutting methods: vaporization cutting, melting cutting, oxygen-assisted melting cutting and controlled fracture cutting. This article uses the melting cutting method to make the material at the laser spot reach the melting point, and at the same time blows or removes it with the help of auxiliary gas The molten material around the hole and the scanning path are set to complete the entire test process. Laser material processing systems mainly include lasers, optical path shaping and transmission systems, motion trajectory control and operating systems, among which lasers are the most important. The laser consists of three parts: the laser medium, the pump […]

Application of laser cutting technology in marine engineering construction

Laser technology is a remarkable achievement in the science and technology industry in the middle and late part of the last century. Its emergence has greatly promoted the progress of human civilization in various industries. In various fields, laser technology has been widely used in recent years, and its application in the offshore engineering and construction industry is also closer to the front line of production. At present, there are mainly four types of plate cutting in the offshore engineering and construction industry, namely flame cutting, plasma cutting, water cutting, and laser cutting. Among them, flame cutting is mostly used in the cutting of medium and thick plates, water cutting […]

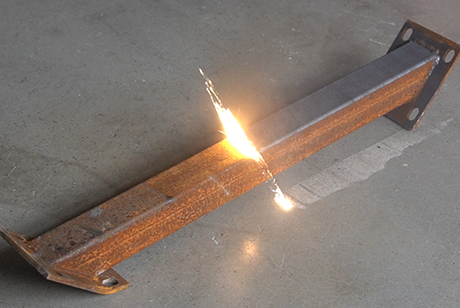

25mm thick carbon steel laser cutting process

Q235B steel is one of the most common steel materials in China, with certain strength, elongation, and good toughness and castability, easy to stamping and welding. Medium plate Q235B steel is widely used in engineering machinery, bridge construction, high-voltage transmission towers, shipbuilding, heavy machinery and large pressure vessels and other industries. In recent years, along with the rapid development of the above industries, the demand for a diversity of changes in these industries, these industries in the parts of many specifications, diverse shapes, some of the higher precision requirements, the traditional processing methods to limit its development. Laser cutting has outstanding advantages such as easy operation, non-contact, high flexibility, high […]

Introduction of robot laser cutting automated production line

1 System composition The production line mainly consists of a feeding system and a discharging system.system, intermediate beam, robot system, laser cutting unit, robot baseSeat, waste collection system, dust removal system, cutting protection room, pneumatic systemand electrical control system.The feeding system includes a feeding rack, a feeding trolley, and a feeding supportRoller and ground pressing device.The discharging system includes a grounded pressing device, a blanking support roller, a blankingDriving roller, slag removal system, back gauge device. 1.1 Send the feeding rack The feeding frame is made up of three sections and is connected with the feeding support roller.Installed side by side, it is the horizontal traveling bracket of the servo […]

Application of laser cutting technology in hydraulic supports

Hydraulic supports are key equipment for fully mechanized mining working faces in coal mines. It plays important roles such as road support and working face support, and at the same time prevents coal lumps, gangue Stones fall onto the mining working face and scraper conveyor to ensure smooth mining. Provide security. The main part of the box structure is mainly composed of top Plate, main floor plate, reinforced plate, transverse floor plate, cover plate, ear plate, side sealing plate and other steel Plate parts are made of tailor-welded parts, and the part cutting technology plays an important role in production quality and efficiency. Rate and cost play a decisive role. […]

Laser Welding vs. MIG Welding: Understanding the Difference and Benefits

Introduction: Embracing Modern Welding Techniques In the realm of manufacturing and construction, the utilization of cutting-edge welding techniques has become pivotal in ensuring superior structural integrity and efficiency. Laser welding and MIG (Metal Inert Gas) welding stand out as two prominent methods revolutionizing the welding industry, each with its unique features and applications. Understanding the distinctions and benefits of these methods is vital for industries seeking to enhance their production capabilities and ensure top-notch weld quality. Laser Welding: Precision and Versatility in Manufacturing Laser welding, a state-of-the-art technique, has gained significant traction in various industries due to its unparalleled precision and versatility. By harnessing the power of focused light beams, […]