- ホーム

- Tube Laser Cutting Machine

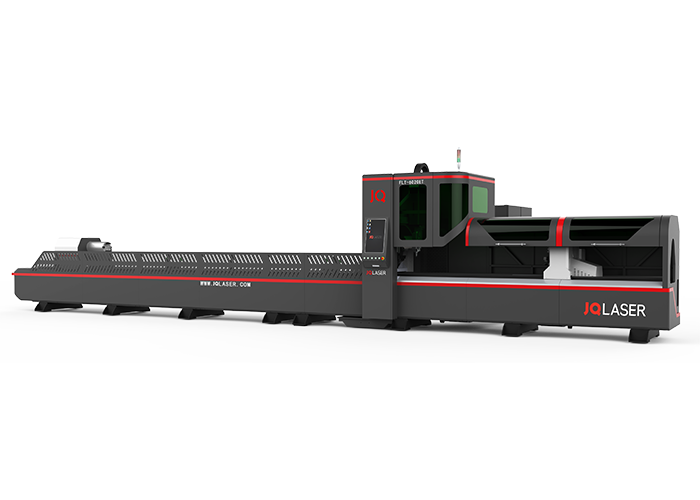

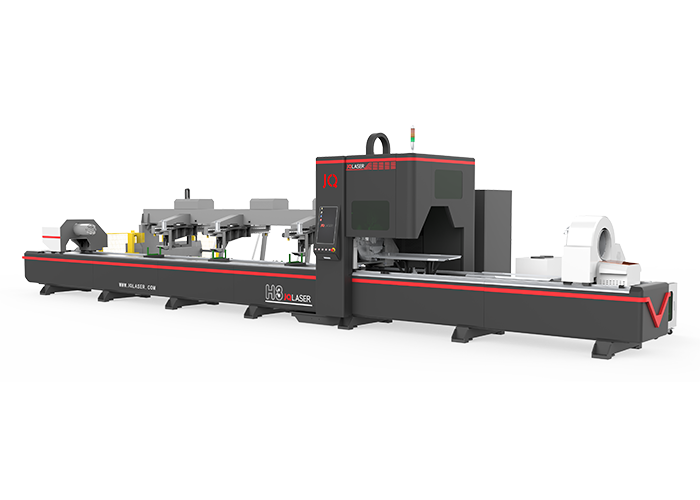

- Heavy Duty Horizontal Three Chucks FLT-6020ET

Heavy Duty Horizontal Three Chucks FLT-6020ET

FLT-6020ET tube laser cutting machine is a high-precision, high-speed, and multifunctional CNC machine. It is mainly used for cutting metal tubes of various materials and shapes. The machine is simple to operate and can be quickly learned by users. With its superior performance, it has been widely used in many industries such as aerospace, shipbuilding, boiler manufacturing, pressure vessel manufacturing, pipeline manufacturing, bridge construction, etc.

Technical Parameters

| Maximum cutting length | ≤6000mm |

| Maximum weight for each tube | 250kg |

| Cutting diameter | 15-200mm O.D. |

| Rotary speed | 120rpm |

| X.Y.Z axis position accuracy | ±0.05mm/m |

| Minimum tailing | 0mm |

| Maximum running speed | 75m/min |

| Power supply | 380V/50Hz |

Components

Feature

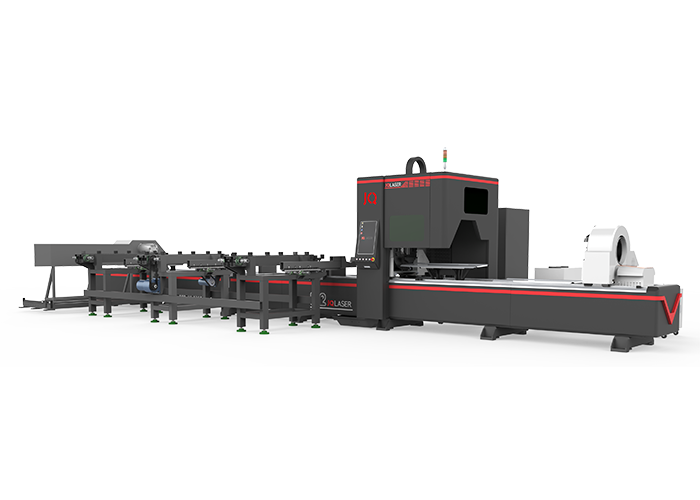

Bed and follower support part

The bed is welded as a whole, annealed to eliminate internal stress, and finished by vibration aging after rough machining, thus greatly improving the rigidity and stability of the machine and ensuring the accuracy of the machine. The machine is equipped with automatic lubrication device, which adds lubricating oil to the moving parts of the bed regularly and quantitatively to ensure that the moving parts operate in good condition, which can improve the service life of guide rails, gears and rack.

The bed is equipped with a follower support mechanism. The auxiliary support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. For rectangular pipes, the system will adjust the pallet height of the pallet assembly in real time according to the outer contour of the pipe to ensure that the pallet supports the pipe stably. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

X-axis, Z-axis, side column and chuck section

The side column is fixed on the bed, welded by steel plate as a whole, annealed to eliminate internal stress, rough machining, vibration aging and then finish machining to ensure the rigidity and stability of the moving parts of the laser head.

X-axis guide adopts high quality linear guide rail and module double guide, driven by servo motor drive screw for transmission, so that the Z-axis sliding plate to achieve reciprocating motion in the X direction. In the process of movement, the limit switch controls the stroke for limiting, and there are also elastic cushion mechanical limits at both ends to ensure the safety of system operation.

The chucks are divided into three groups of pneumatic chucks, front, middle and rear, and the three groups of chucks are driven by servo motors to move and rotate synchronously in the Y-axis direction. Under the logic action set by the system, it can realize the pulling type cutting of the pipe, which can greatly improve the cutting accuracy and can conditionally realize the zero tail material cutting (depending on the workpiece cutting size and specific cutting process).

The Y-axis movement drive rack, linear guide and W-rotation drive gear of the chuck are all made of high precision products, which effectively ensure the accuracy of transmission; each group of chucks is controlled by limit switches and equipped with hard limit devices, which effectively ensure the safety of machine movement.

Z-axis device is mainly to realize the up and down movement of laser head. The up and down movement of the laser head is done by the servo motor driven linear module controlled by the CNC, which drives the laser head up and down reciprocating movement. The upper and lower ends are controlled by proximity switches to ensure the safety and reliability of the movement. The linear modules are all made of high quality products to ensure the accuracy of transmission.

The capacitive sensor in the Z-axis device detects the distance from the nozzle to the surface of the plate and then feeds the signal to the control system, and then the control system controls the Z-axis motor to drive the cutting head up and down, thus controlling the constant distance between the nozzle and the plate and effectively ensuring the cutting quality. The position of the focal point is adjusted according to the material and thickness of the cutting material, thus obtaining a good cutting section. So Z-axis can be used as a CNC axis for interpolation movement with X, Y and W axes, and it can also be switched to follower control to meet the needs of different situations. Since the Z-axis follower is also controlled by the CNC system, the follower has high precision and good stability, thus ensuring the quality of cutting.

Depending on the laser head model, the laser head can adjust the focus automatically or manually.

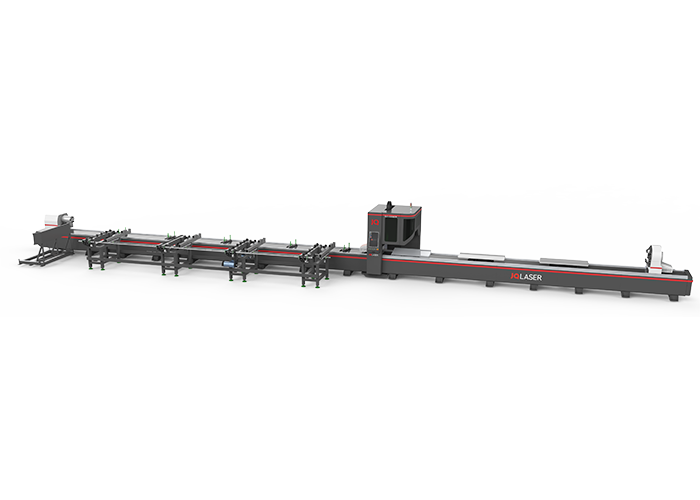

Follow-Up Front Splicing

There are 2 groups of follow-me front feeders. Both of them use servo motor driven screw to control the rise and fall of the receiving plate, which holds the pipe when the cut pipe is long and prevents it from sagging. For rectangular pipe, the system will automatically calculate and adjust the height of the pick-up plate in real time according to the outer contour of the pipe to ensure that the pick-up plate supports the pipe stably.

According to the length of the workpiece, the system will automatically control the receiving action of 2 groups of receiving devices, i.e. synchronous lifting and turning, and only one of the components can be used for independent action, and the receiving plate can be automatically turned over for unloading, and the position of the lower feed opening can also be used to achieve waste screening, making the machine more intelligent, convenient and efficient.

Electrical control system

FLT-6020ET three-chuck pipe cutting machine electrical control system is mainly composed of the bus type system of 5000A, servo system and low voltage electrical system.

system and low-voltage electrical system.

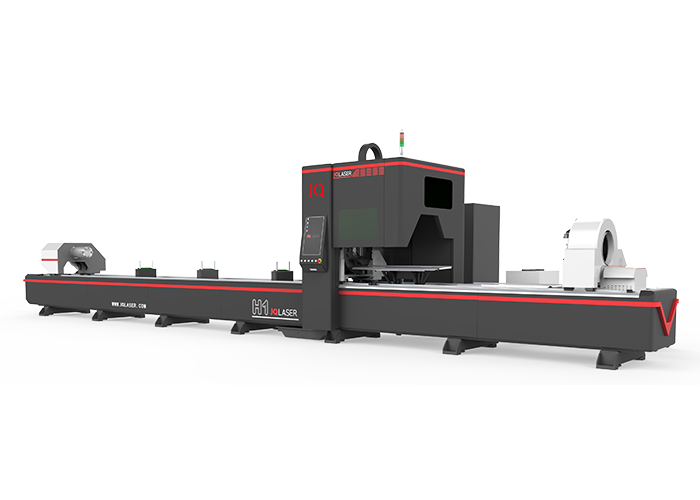

Bed part

The bed is made of welded pipe, the inner part is steel pipe, the outer part is made of 3mm steel plate, annealed after welding to eliminate internal stress and then machined, which greatly improves the rigidity and stability of the machine and ensures the accuracy of the machine.

The Y-axis rack and linear guide are made of high precision products, which effectively ensure the accuracy of the transmission; the limit switch control at both ends of the stroke and the hard limit device are equipped, which effectively ensure the safety of the machine movement; the main machine is equipped with automatic lubrication device, which adds lubricant to the moving parts of the bed at regular and quantitative intervals. The main machine is equipped with automatic lubrication device, which can add lubricating oil to the moving parts of the bed regularly and quantitatively to ensure that the moving parts run in good condition, which can improve the service life of guide rails, gears and rack.

Crossbeam and X-axis and Z-axis devices

The crossbeam is annealed to eliminate internal stress, rough machining, vibration aging and then finishing to ensure the rigidity and stability of the moving parts of the laser head. x-axis and z-axis are driven by high precision modules, in the process of movement, the limit switch controls the travel to limit, and at the same time there are elastic cushion mechanical limit at both ends to ensure the safety of the system operation.

Z-axis device is mainly to achieve the up and down movement of the laser head. The up and down movement of the laser head is controlled by the CNC system servo motor, which drives the linear module to drive the Z-axis slide plate up and down reciprocating motion to complete. The upper and lower ends are controlled by proximity switches to ensure the safety and reliability of the movement.

Electrical control system

The electrical control system of FLT-6016LN series fiber optic pipe cutting machine is mainly composed of Pachu CNC system, servo system and low voltage electrical system. The laser cutting machine is equipped with high performance Pachu CNC system, which is a WINDOWS-based PC CNC system with fast interpolation and easy operation; the servo system is an imported AC servo motor and driver, which is stable and reliable, with good dynamic performance, strong load carrying capacity and easy operation. The machine operation soft keys can have different functions in different operation modes, thus reducing the operation buttons and simplifying the operation panel. The operation functions are displayed by menus in various ways, making the operation intuitive.

frequently asked question

Do you have CE? We provide you with CE in the form of a one-stop service. At first, we will demonstrate CE to you. After delivery, we will give you CE packaging list a commercial invoice for customs clearance.

Please tell us about your following answer, our specialist will provide advice on proper power. 1. What material you want to cut, stainless steel, carbon steel or other? 2. What thickness do you want to cut?

If confronted with any problems, please contact us immediately and do not attempt to fix the machine by yourself or anyone else. We will respond within 24 hours as quickly as we can to help you.

2 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Yes, we are happy to provide advice and we have dedicated technicians all around the world who are ready to assist you. Your operations’ continued success relies on your machines staying in working order.

Leave Message And Get The Answer

In order to improve the user experience and improve our production technology, JQ laser has been collecting real machinery handling questions and comments from the market, which we will analyze and provide answers to, and we will also adopt the favorable production ideas.