Introduction: The Power of Laser Cutting

The power of laser cutting is impressive. It is a technology that can provide precision cutting of tubes and other materials in a quick, efficient manner. It is an essential part of modern manufacturing and can be used for a range of applications including tube fabrication and connecting pipes. This article will look at the technology that makes laser cutting possible, the advantages it brings, and the impact Chinese innovation is having in the global marketplace.

A History of Tube Cutting: Traditional Methods vs. Modern Technology

Before laser cutting was invented, traditional methods of cutting materials such as tubes were labor and time-intensive. Tube cutting used to involve drilling of holes, manual splitting, sawing and grinding with tools such as hacksaws, band saws and drill presses. This often resulted in significant deformation of the material, wasted time and high costs. However, modern laser cutting revolutionised the process by creating more accurate and efficient results. It is believed that laser cutting was developed in the 1960s, but it was not until the late twentieth century that it started being used in industry. The use of lasers to cut materials is now the norm and the technology is growing exponentially.

The Rise of Chinese Innovation in Laser Cutting

China has been a major innovator in the field of laser cutting, providing a range of solutions and equipment. Chinese manufacturers have developed cutting-edge laser cutting machines that use both existing designs as well as technologies and techniques developed in-house. Furthermore, Chinese-made lasers are designed with cost efficiency in mind. They are relatively inexpensive compared to Western-made solutions, making them ideal for small businesses and startups. Moreover, Chinese manufacturers provide after-sale support and training services that help users get the most out of the technology.

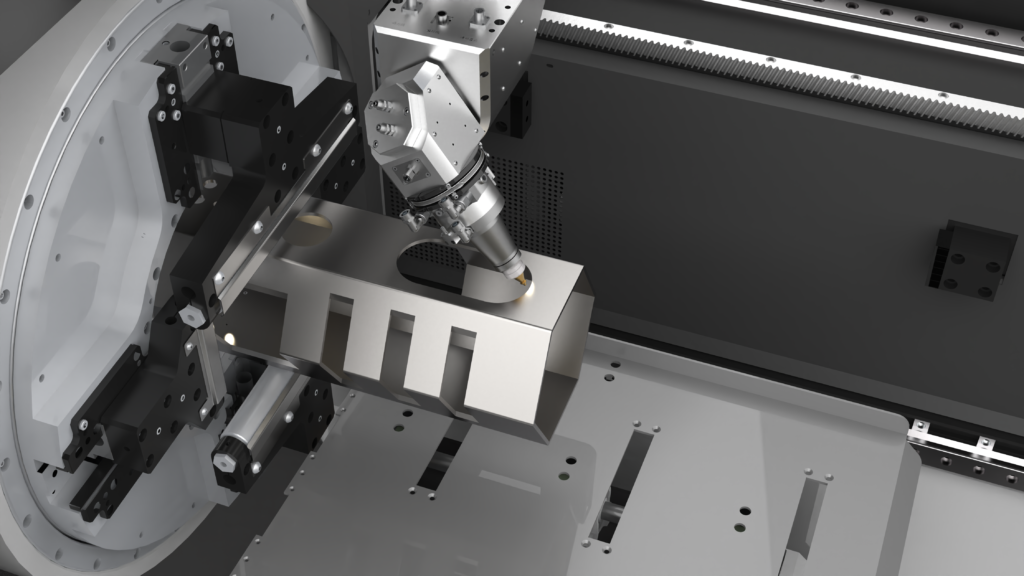

Making the Cut: How Laser Cutting Works

At a basic level, laser cutting works by using a beam of high-energy light (a laser) to heat and melt material. This enables laser cutters create precise shapes and designs with minimal material loss. The duration and energy of the beam is then used to determine the shape, width and depth of the cut. It is an extremely fast process, as a laser cutter can make thousands of cuts in a short period of time.

The Advantages of Laser Cutting for Tube Fabrication

There are a number of advantages to laser cutting when used in tube fabrication. Firstly, it is more accurate than traditional methods, creating sharper edges and cleaner cuts. It can also handle delicate materials such as aluminum and plastics, allowing for more intricate designs. Laser cutting also offers greater flexibility in terms of shapes and cuts, meaning it can be used in a range of applications. Finally, laser cutting is a time-efficient process. Large-scale projects can be completed in a much shorter time frame than traditional methods, reducing production costs and speeding up lead times.

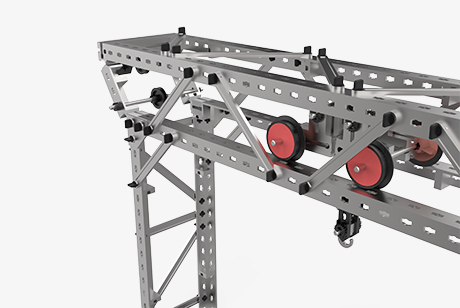

Equipment and Techniques: Cutting Edge Technology in Chinese Manufacturing

There are a number of different kinds of industrial laser cutters used in Chinese manufacturing. These range from CNC machines to OEM/ODM machines. CNC machines are highly automated and use computer-aided design and mathematical algorithms to process data. ODM/OEM machines are designed for a specific purpose and are commonly used for custom parts and volume production. Additionally, the Chinese have developed specific techniques and technologies to streamline the process of laser cutting. These technologies include special software programs that can be used to control the laser beam and process data, reducing the time and manpower needed to complete a task.

Future Trends in Laser Cutting: What’s on the Horizon?

The use of lasers for cutting materials is still in its infancy and there is much room for improvement. Laser cutting technology is growing rapidly and in the future, we can expect to see faster, more accurate results. Furthermore, we anticipate more powerful lasers being developed that are able to cut through harder materials such as steel and stone. Another trend is the use of 3D laser cutters. These machines use a combination of specialized software and lasers to cut through 3D objects and can also be used to create intricate patterns. Finally, we expect to see further integration of machine learning and artificial intelligence in laser cutting technology. This means that machines may soon be able to work with little or no human intervention.

Conclusion: The Impact of Chinese Innovation in the Global Marketplace

Laser cutting is revolutionising the way materials are cut and Chinese innovation has been a major factor in this technology’s development. Not only have Chinese manufacturers developed cutting-edge equipment, but they have also developed sophisticated techniques and technologies that are transforming the way tubes and other materials are fabricated. In the future, we can only expect Chinese innovation in laser cutting to become even more influential, as this technology continues to evolve and become more advanced. This will result in greater efficiency and accuracy in the global market and have a transformative impact on the way we fabricate materials.