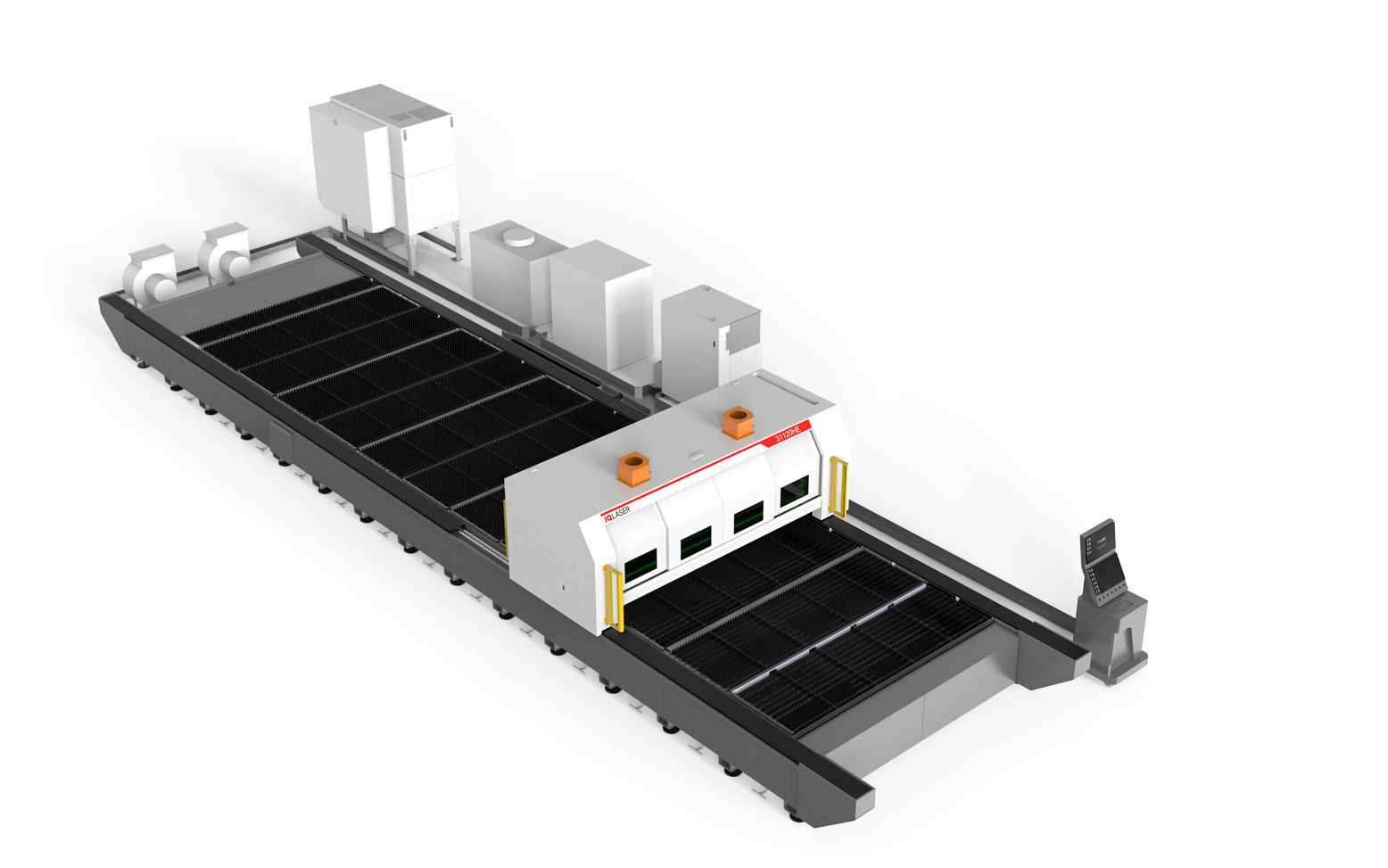

JQ-31120HE

Start off on the right foot

Plate cutting

Power available

6KW – 60KW

Loading weight

2000KG

Working area: 3100*12000mm

X-axis travel: 3100mm

Y-axis travel: 12100mm

Z-axis travel: 380mm

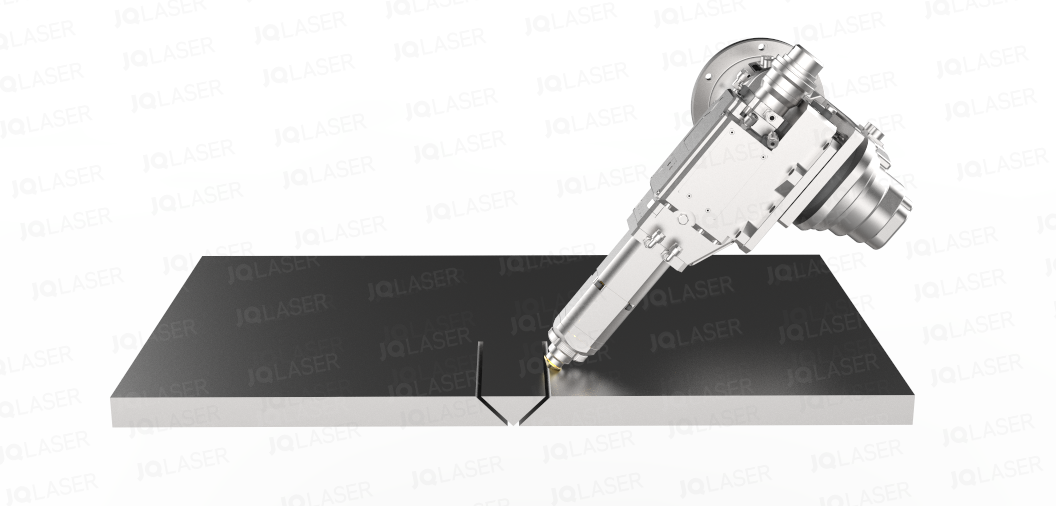

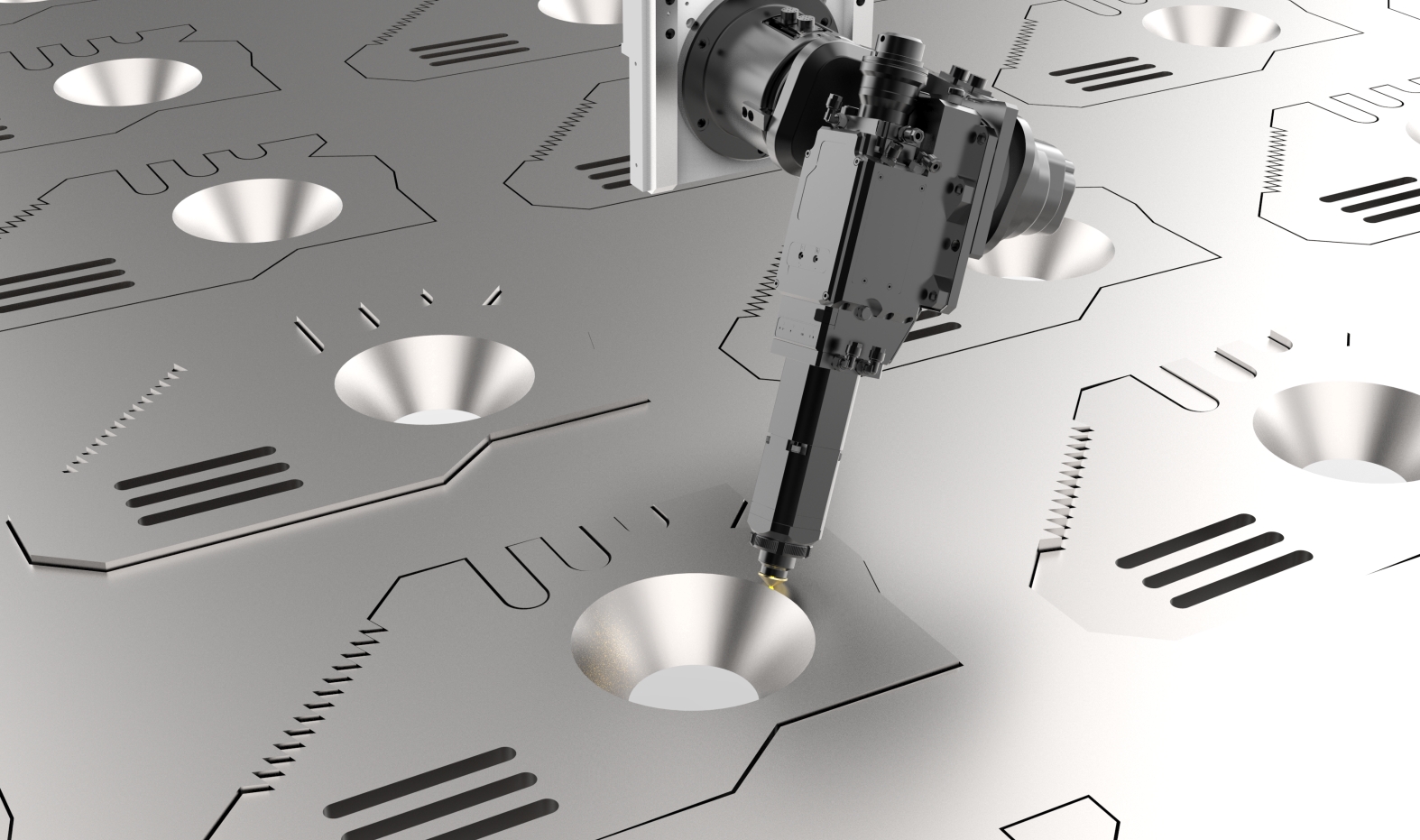

Autofocus Bevel Cutting Head

It can achieve 45° bevel and flat cutting, and is equipped with intelligent technologies such as air pressure monitoring, lens temperature monitoring, collision prevention, and explosion protection. The system is easy to debug, offers stable cutting, and delivers excellent performance.

For 6~40KW flat bevel cutting applications, we have developed a 4-axis + AB-axis product combination.

Ergonomic and accessible

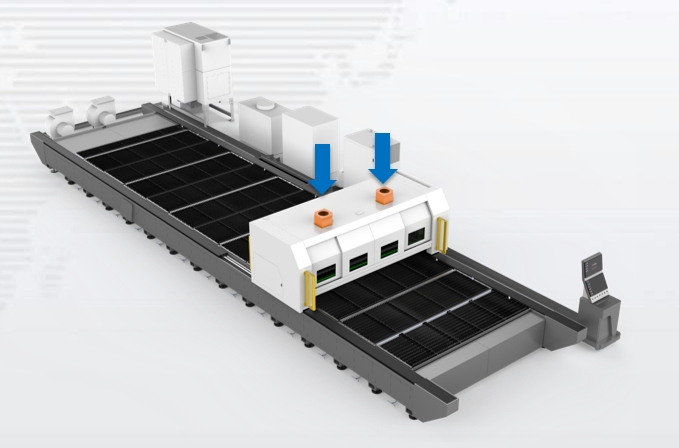

Shipping solutions such as shipping in a container without removing sheet metal and beams

The sheet metal shield dust removal system adopts the design of upper pressure wind + lower partitioned exhaust: The cutting area is equipped with a protective cover to effectively limit the damage to the human body caused by the laser beam, cutting smoke, etc.; The equipment is equipped with a cross-flow fan design to ensure timely collection of smoke and dust, and a special smoke integrator is installed on the rear side to effectively collect internal smoke and heat;

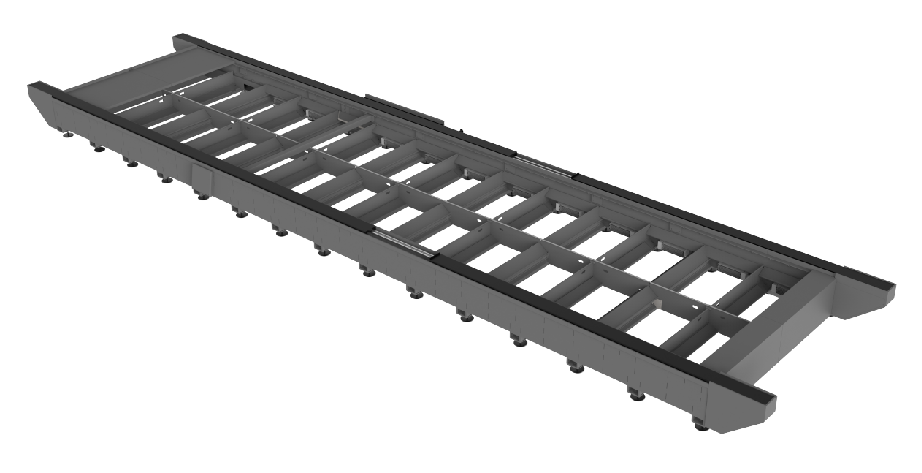

The bed structure adopts a plate-welded box-type frame structure, with reasonable arrangement of rib plates and plug-in structure for key connection parts. Under the premise of maximum strength use, the burning area is reduced to avoid thermal deformation of the bed. At the same time, strict welding process is formulated, and annealing and stress relief treatment are carried out to ensure the stability of the bed.

The best choices show their value over time

- ull cover model, with four sliding doors on the front

- Observation windows (OD6+) to better protect operators from using or observing the equipment status

- There is an inspection door on the left/right side for easy maintenance. The front sliding door is convenient for observing and replacing the nozzle and protective lens

- A dedicated wide-angle camera is installed inside the equipment to observe the real-time status of the equipment cutting process

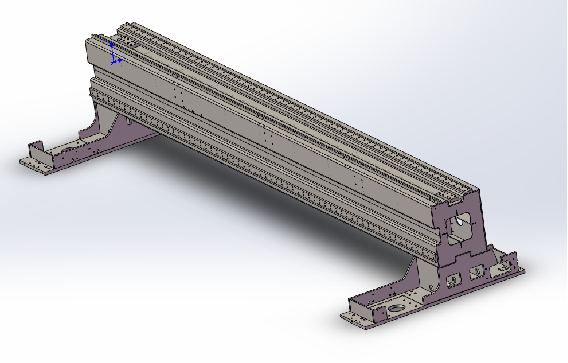

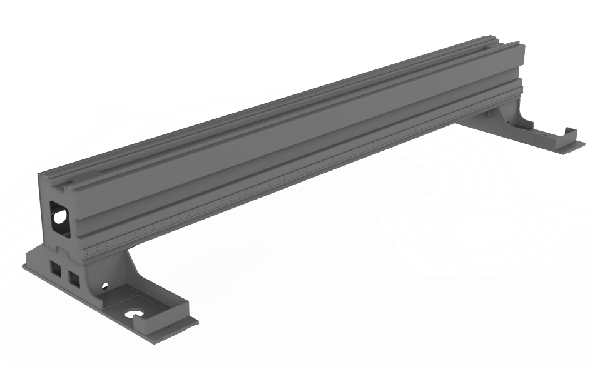

The crossbeam adopts high-strength welded steel crossbeam, and the steel crossbeam adopts plug-in structure. Strict welding process is formulated, and annealing and stress relief are carried out to ensure the stability of the crossbeam. The interior of the crossbeam adopts a cage-type plug-in rib plate design, and the external bending “J” shape bend increases the strength. While lightweight, each force-bearing surface is individually set with reinforcing ribs to enhance the dynamic response of the movement to the extreme.

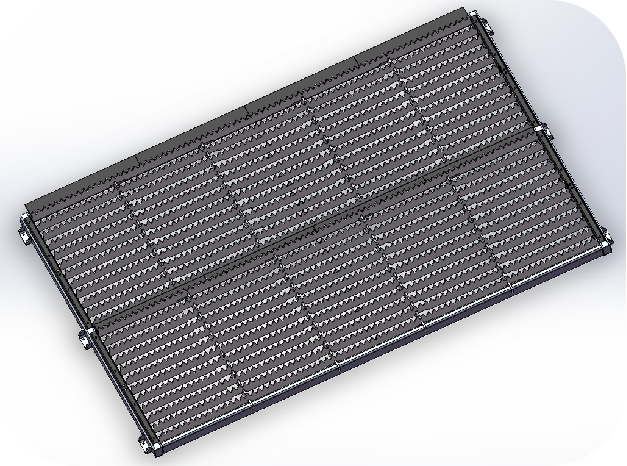

Table frame assembly:

Modular arrangement of blades; Staggered arrangement of blade tips, providing effective three-point support; Graphite plates are used for high-power burn-proof, which increases service life and facilitates slag removal;

Intelligent Electrical Systems

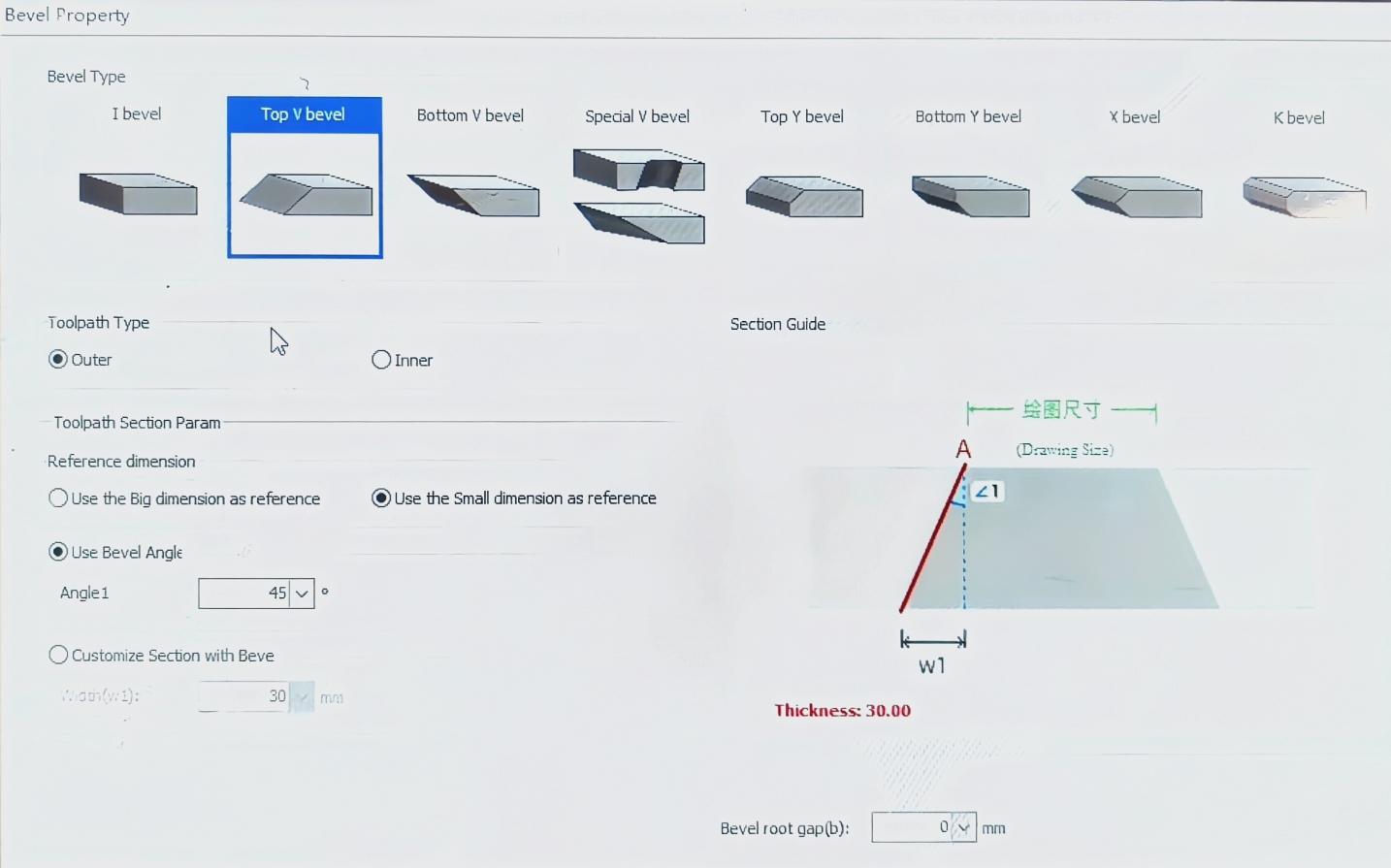

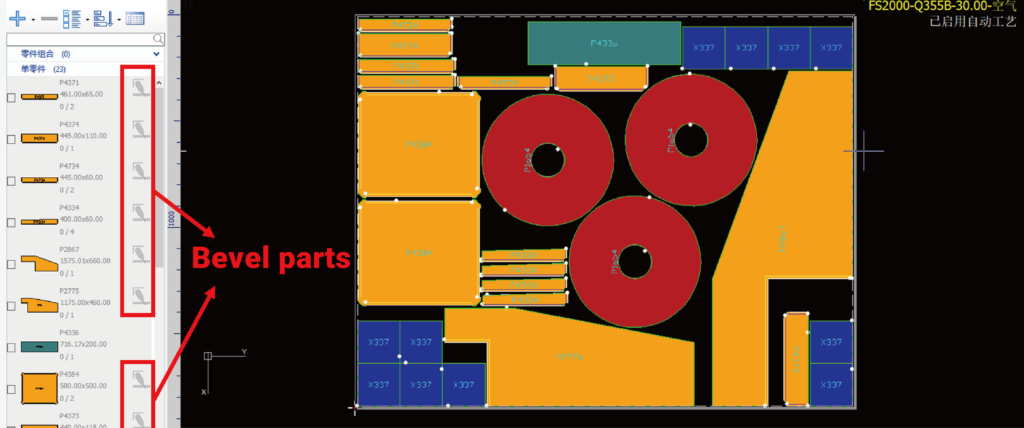

CypNest professional nesting software supports the import of CAD/Tekla/Tribon (AM) parts, bevel editing, and mixed nesting of straight-cut and bevel parts, greatly simplifying the workflow from drawing to nesting to processing.

Its unique algorithm compensates for material deformation, effectively improving the bevel processing accuracy.

Bevel layout

The software suite that creates value

CypNest professional nesting software supports CADЛTekla/Tribon (AM) part import, groove editing, and mixed nesting of straight-cut groove parts, greatly simplifying the process of drawing-layout→processing. It is suitable for medium and high-power plane groove cutting, with efficient and easy-to-use mechanical calibration, precision compensation, and groove nesting solutions, and is widely used in various sheet metal processing scenarios.