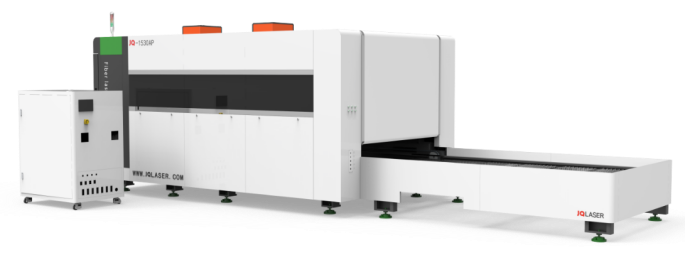

Main Features

√ Heavy duty machine base.

√ High power servo motors.

√ Smart cutting control system, easy operation;

√ Quick piecing, supported by segment and step piecing technology;

√ Specialized air duct with out sized caliber, makes smoke exhaust smooth.

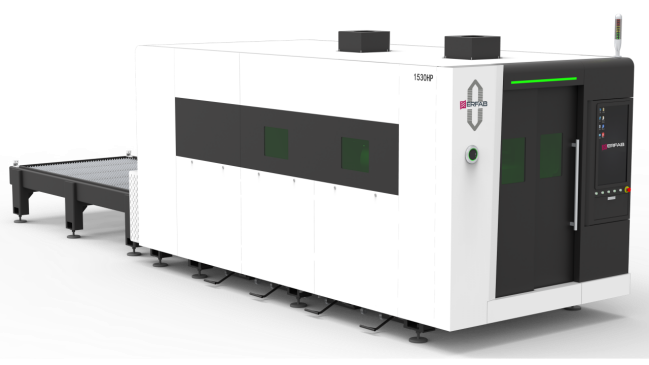

√ Fully enclosed design;

√ European CE Standard laser protection.

√ Dual shuttle tables provides high level of safety and convenience.

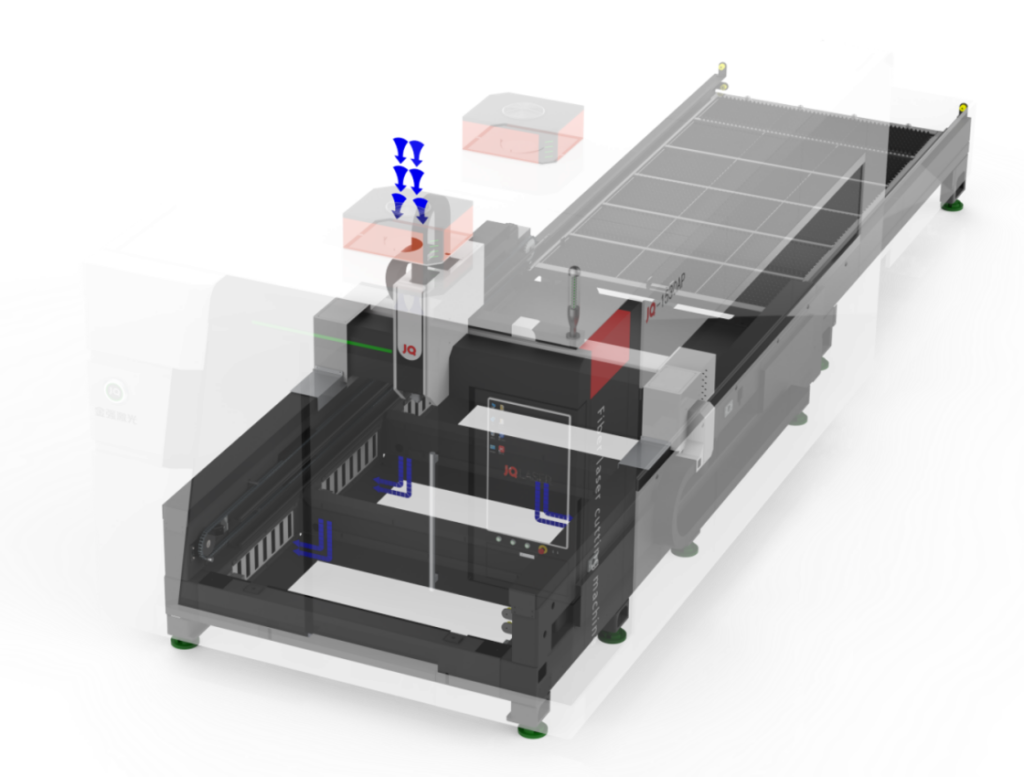

Mechanical Features:

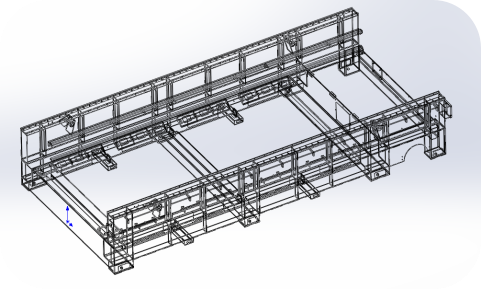

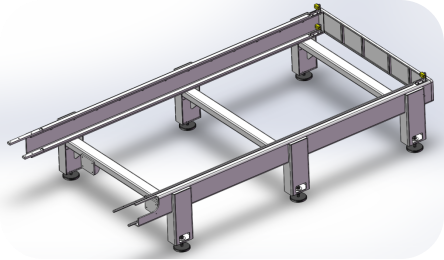

MachineBody

The bed structure adopts a plate welded box frame structure, the ribs are reasonably arranged, and the key overlaps adopt a plug-in structure. Strict welding processes are formulated and annealed to remove stress and undergo aging treatment to ensure the stability of the machine bed.

The machine width is 2260mm, which enables the entire container to be loaded into the container without disassembling sheet metal and beams.

Use cast iron plates for heat insulation and burn prevention.The installation of cast iron plates is better than that of graphite plates. Cast iron adopts hooking, while graphite plates need to be installed and fixed with separate sheet metal. The strength of cast iron is better than that of graphite plate. Cast iron is not brittle and has a long service life, while graphite has a short brittle period (30rmb/KG). Because cast iron contains relatively high carbon content, it is difficult to fuse with ordinary slag, is easy to clean, and can be used repeatedly;Cast iron has a relatively high residual value, but graphite plate does not.

The installation straightness and parallelism of the guide rail and rack adopt the collimator + tooling detection method. Runout requirements for reducer gear installation, within 0.03mm.The wiring in the cutting area is protected, and the external wiring is provided with wire troughs.

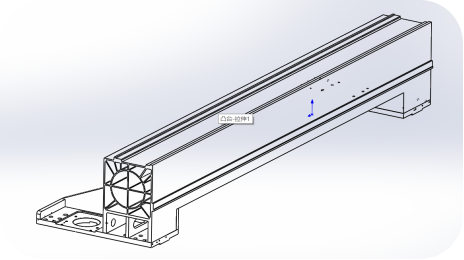

Aviation Aluminum Gantry

The cross beams are made of aviation-grade high-strength aluminum alloy, and the extruded aluminum profile structure adopts an outer square inner circle + cross partition composite structure. While being lightweight, each stress-bearing surface is individually provided with reinforcing ribs to maximize the dynamic response of motion. It is required that 0.02 feeler gauge does not enter between the cross beam and the positioning surface of the guide rail pressure block. Make sure it is close.

The cross beam adopts fixed + floating positioning method to ensure the stability of high-speed movement.

Exchange Platform

The rear bed adopts a continuous structural layout, which effectively improves the stress characteristics and is lightweight to ensure aesthetics. It does not require sheet metal and is simple and elegant.

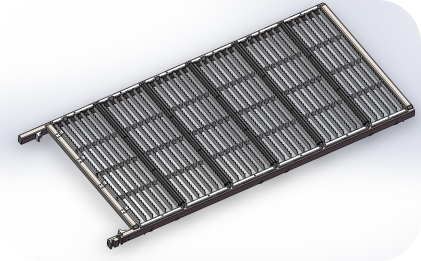

Countertop frame components

Adopt modular arrangement of knife strips.

The staggered arrangement of the tool tips can provide effective three-point support.

High-power anti-burning uses cast iron bars to extend service life and is easy to clean.

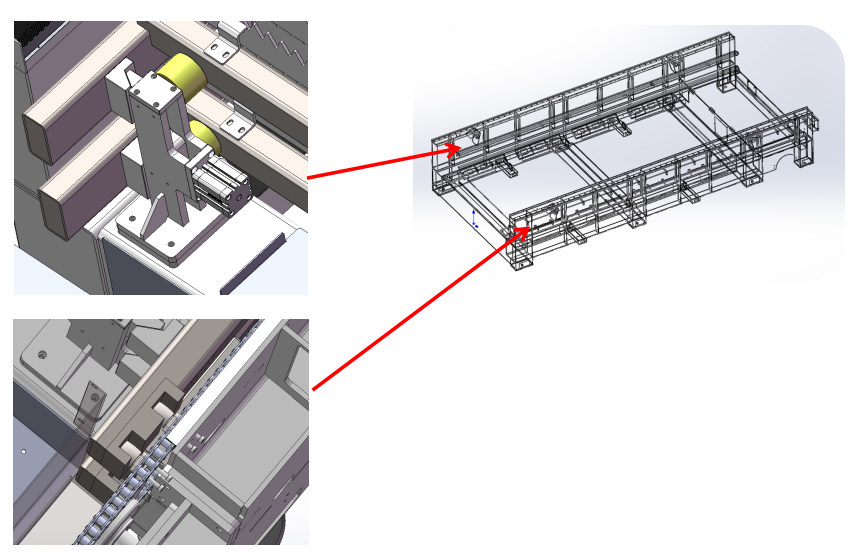

Countertop frame locking and transmission

Use 2 high-rigidity gates to lock the worktable to prevent shaking during cutting and ensure cutting accuracy. The transmission adopts double transmission shaft design to ensure effective transmission of torque.

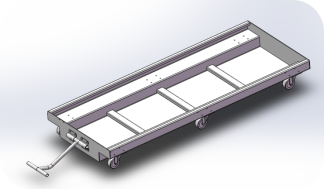

Material receiving truck

The handle adopts a T-shaped mechanism, which is easy to push and pull with both hands, and it also curves upward to facilitate workers to quickly access it. The main structure of the box adopts an inverted “J” bending + transverse channel steel design, which can effectively strengthen the structure and reduce thermal deformation. The bed is equipped with a guide structure + limit baffle, which facilitates the pushing and pulling of the material truck.

Positive-pressure Protection with Strong Ventilation

The ventilation area is equipped with valve damper and divided into three zones. Suction Zone keep closed untill the laser head is above. Thus has strong and intensive suction. It is noiseless while opening and closing. Due to the large pipeline, cutting smoke will be discharged smoothly; The machine bed is always full of positive pressure. In combination with strong ventilation system below, smoke dust will disappear rapidly to offer you clean working environment.

Professional Automation Control System for Laser Cutting Machine

Medium power laser cutting system is a full-solution open-loop control system specially designed for sheet metal fabrication industry, with features of easy to install and adjust, excellent performance and fully integrated solutions.

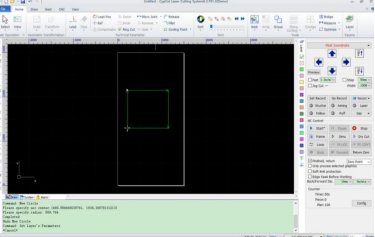

Smart HMI Interface

General functions include graphics processing, parameter settings, custom cutting process editing, nesting, path planning, simulation, and cutting process control. Supports speed-dependent power adjustment and can set separate lead-in line speeds. The material process library function allows all process parameters to be saved for reuse of the same material.The touch screen (32-inch) control interface saves space and liberates the long-term use of hands

Anti-collision Height Controlling Z axis

Z axis is equipped with capacitive height controller in order to provides excellent performance in distance control. provides excellent performance in distance control. It also support vibration suppression to restrict laser head resonating with vibrated thin sheet under pressured gas. Work with cutting software can realize the functions of ‘find workpiece edge’, ‘frog-leap’ and ‘stepping.

Powerful Cutting Head

Specific functions of BM06K cutting head

√ Updated version from BM06K with stable cutting capability under continuous full power.

√ Upgraded optics beam and gas circuit.

√ Integrated design to ensure sealing.

√ Both collimation and focus lens are water cooled.

√ Air cooling to nozzle which effectively protecs the nozzle & ceramic part and extend the lifespan.

√ Compact structure to reduce the payload of Z axis.

√ 35mm clear aperture to effectively reduce stray beam interference and guarantee cutting quality and lifespan.

√ Auto focus to reduce human intervention.

If the power reaches 12KW, BOCI laser cutting head will be used

BOCI is a cost-effective intelligent cutting head developed for a variety of processing equipment such as flat surfaces, bevels, pipes, etc. It is easy to install, simple to debug, has excellent performance and stable cutting.

The BLT6 series is an intelligent cutting head developed for ultra-high-power laser equipment (the highest power can support 40KW). It has a new optical path design and optimized optical lenses. It is easy to install, simple to debug, has excellent performance, is double dust-proof, and has stable cutting. The perforation detection and process monitoring functions can effectively improve production efficiency and product yield, and meet the strict performance requirements of air and nitrogen high-power cutting.

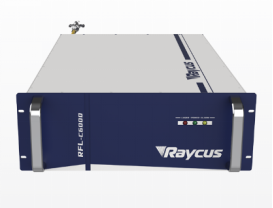

Laser Source

Raycus High Power CW Fiber Laser

Single-mode CW fiber lasers have the advantages of high electro-optic conversion efficiency, good beam quality, high energy density, wide modulation frequency, strong reliability, long life, and maintenance-free operation. It can be widely used in welding, precision cutting, cladding, surface treatment, 3D printing and other fields. Its fiber optic output feature makes it easier to integrate with robots into flexible manufacturing equipment for metal processing needs.

Technical characteristics

√ High Electro-optical Conversion Efficiency

√ Customized Output Fiber Length

√ Output cable:QBH/QD

√ Maintenance-free Operation

√ Wide Modulation Frequency Range

√ Small Size, Easy to Install

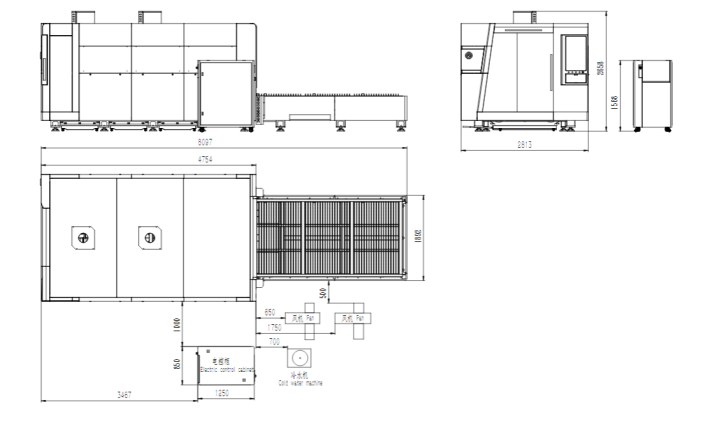

Machine Parameters

| Technical Parameters | |

| Working area | 3000×1500mm |

| X-axis travel | 1550mm |

| Y-axis travel | 3050mm |

| Z-axis travel | 370mm |

| Repositioning accuracy | ±0.03mm/m |

| Positioning accuracy | ±0.05mm |

| Maximum linkage speed | 140m/min |

| Maximum linkage acceleration | 1.5G |

| 1mm steel plateφ30 roundness | 0.1mm |

| 1mm steel plate□30 adjacent margin | 0.05mm |

| Maximum load | 1500KG |

Machine Configuration

| Item | Brand | Model | Unit |

| Servo Motor | Yaskawa | X: 1.8kw; Y:0.75kw; Z:0.4:kw | 4 sets |

| Exchange motor | Deli | 3kw | 1 set |

| Linear Guide rail | HIWIN | Y #30 X#25 | Whole sets |

| Gear rack pinion | YYC | 2M | Whole sets |

| Laser source | Raycus | 6kw | 1set |

| Laser head | Raytools | BM06K | 1set |

| Chiller | Tongfei/ Hanli | 1.6/2.4/3.3/3.8 kw | 1set |

| Air conditioner (Optional) | Tongfei | China | 1set |

| Low voltage electrical components | CHINT | Switch/Relay | Whole sets |

| Industrial computer | Yanhua | Windows system | 1 set |

| Lubrication system | China | DAMAITIAN | 1 set |

| Touch screen | Jinkong | 32INCH | 1 set |

| Control system | FSCUT | FSCUT 4000E | 1 set |

Optional

Adjust on length of loading, unloading

| Available for expansion | ||||

| X axis | 1500mm | 2000mm | 2000mm | 2500mm |

| Y axis | 4000mm | 4000mm | 6000mm | 6000mm |

Nesting software

The nesting software designed for sheet laser cutting system. It integrates advanced functions of drawing modification, quick nesting, toolpath generation, analysis report and more to meet your production needs.

Dust collector

Under the strong negative pressure of the turbo fan, when the polluted air duct enters the air inlet, it first encounters the spoiler between the air inlets, which makes the entering gas deteriorate and the flow velocity slows down. Due to the gravity settling, the coarse dust falls directly into the large particle dust port, which plays the role of pre-dust removal. After the fine-grained and low-density dust particles enter the dust filter chamber, the dust in the air stays on the surface of the filter element, and the filtered clean air enters the air chamber, and is collected by the exhaust pipe to the air outlet and passes through the fan.

Safety light curtain

Safety light curtains are installed at four points of the rear bed to prevent personnel from approaching and avoid casualties. Safety light barriers can be used to replace traditional mechanical barriers or other forms of mechanical protection, and can also increase the maintainability of equipment. Cooperating with safety light barriers, it can also increase the operability and efficiency of mechanical equipment.

Cutting ability for reference

Layout