In today’s world of manufacturing and engineering, precision is key. When it comes to laser metal cutting, achieving precision can be challenging, especially when dealing with edges that are hard to access. This article will delve into the various strategies and techniques that can be employed to overcome edge inaccessibility in laser metal cutting processes. From advanced technology to innovative approaches, we will explore how manufacturers are pushing the boundaries of precision in this vital industrial process.

1. Introduction: The Importance of Precision in Metal Cutting

Precision is the cornerstone of modern manufacturing. Whether it’s crafting intricate components for aerospace or creating precise parts for medical devices, the ability to cut metal with utmost accuracy is non-negotiable. However, achieving this level of precision becomes a complex endeavor when dealing with edges that are difficult to access.

2. The Challenge of Edge Inaccessibility

Edge inaccessibility refers to the areas of a metal workpiece that are hard to reach using conventional cutting methods. These areas often include tight corners, complex contours, and sharp angles. Traditional metal cutting techniques struggle in such scenarios, leading to compromised quality and increased waste.

3. Advanced Laser Cutting Technologies

3.1 Fiber Laser Cutting

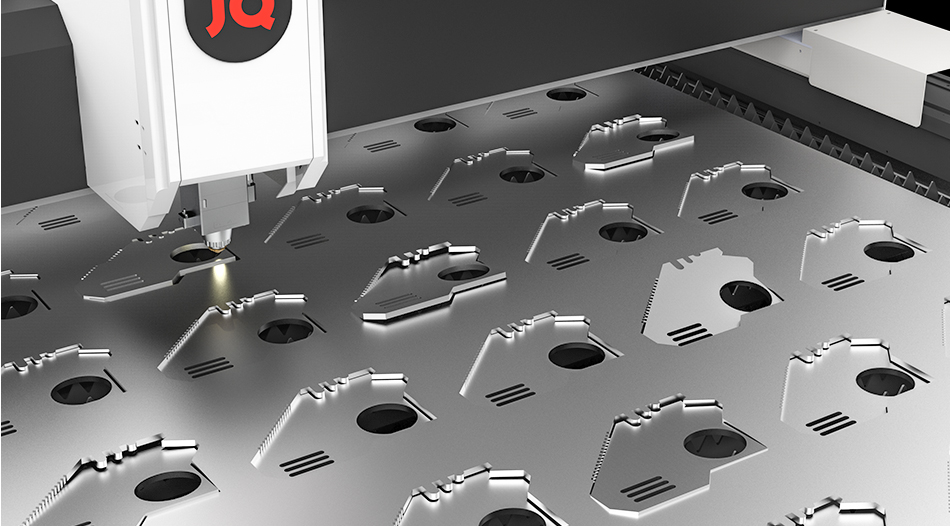

Fiber laser cutting has emerged as a game-changer in the world of precision metal cutting. Its concentrated beam of light can navigate the most intricate of geometries with ease. Fiber lasers are highly effective in overcoming edge inaccessibility challenges.

3.2 CO2 Laser Cutting

CO2 laser cutting, while not as precise as fiber lasers, offers significant advantages in terms of versatility and cost-effectiveness. Combined with advanced optics, CO2 lasers can handle complex edge profiles.

4. Overcoming Access Limitations

4.1 Nozzle Manipulation Systems

To address edge inaccessibility, nozzle manipulation systems have been developed. These systems can precisely position the cutting nozzle to tackle hard-to-reach areas, ensuring consistent quality throughout the cutting process.

4.2 Adaptive Optics

Adaptive optics technology adjusts the laser beam’s focus dynamically, allowing it to maintain optimal cutting performance even in challenging edge scenarios. This innovation is a boon for industries that demand uncompromising precision.

5. Innovative Approaches

5.1 3D Laser Cutting

3D laser cutting systems have revolutionized precision metal cutting. By offering multi-axis control, they can maneuver around edges effortlessly, making them ideal for intricate and three-dimensional workpieces.

5.2 Robotics and Automation

Combining robotics with laser cutting technology opens up new possibilities for overcoming edge inaccessibility. Robots can access tight spaces and perform consistent, high-precision cuts.

6. Ensuring Safety and Quality

Maintaining safety and quality in laser metal cutting is paramount. Proper ventilation and safety measures must be in place to protect workers, and regular maintenance of cutting equipment is essential to ensure consistent results.

7. The Future of Precision Laser Metal Cutting

The future holds even more promise for precision laser metal cutting. Advancements in artificial intelligence and machine learning will enhance the adaptability and precision of cutting systems. The quest for perfection in manufacturing continues.

8. Conclusion

In the ever-evolving world of metal cutting, overcoming edge inaccessibility is a challenge that industry leaders are tackling head-on. Through advanced laser cutting technologies, innovative approaches, and a commitment to safety and quality, precision in metal cutting is reaching new heights.

9. FAQs

Q1: Are laser cutting technologies expensive to implement?

Laser cutting technologies can have an initial cost, but their long-term benefits often outweigh this. Increased precision and reduced material wastage can lead to significant savings.

Q2: What industries benefit the most from precision laser metal cutting?

Precision laser metal cutting is crucial in aerospace, automotive, medical device manufacturing, and electronics industries, among others.

Q3: How can I ensure the safety of workers during laser metal cutting?

Proper training, safety gear, and well-ventilated workspaces are essential to ensure the safety of workers in laser metal cutting environments.

Q4: Can laser cutting be used on all types of metals?

Laser cutting can be used on a wide range of metals, including steel, aluminum, and copper, but the specific laser and settings may vary depending on the material.

Q5: What role does software play in precision laser metal cutting?

Advanced software controls the laser cutting process, ensuring precise, automated cuts. It also enables the customization of cutting patterns for different applications.