With the increasing popularity of laser cutting, it is important to consider the environmental impact of this technology and how it can be used in a more sustainable way. Laser cutting offers many advantages to businesses, such as its ability to produce detailed and accurate results with minimal waste. However, there are still certain sustainability considerations that should be taken into account when using this technology.

Laser Cutting

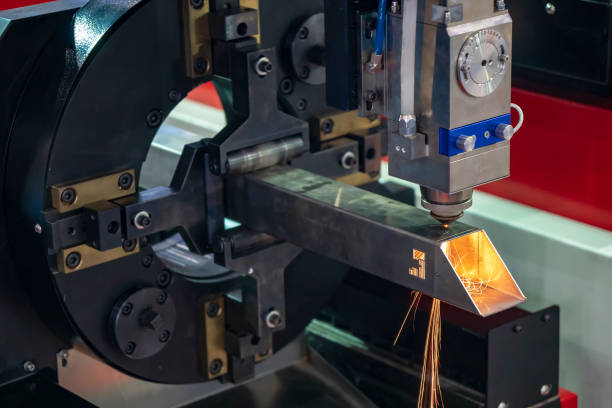

Laser cutting is a widely used manufacturing process that has been gaining popularity among businesses of all sizes, due to its precision, speed and cost-effectiveness. However, it’s important to consider the environmental implications of laser cutting. As with any industrial process, there are sustainability considerations to keep in mind when it comes to 레이저 커팅. The use of 레이저 커팅 can lead to air pollution from toxic gases generated during the process. These gases can be dangerous if inhaled or breathed in directly. In addition, the high temperatures involved in 레이저 커팅 can also cause an increase in energy consumption as well as water usage for cooling purposes. Furthermore, using lasers requires special protective equipment like eye protection and masks which must be disposed of correctly in order avoid contamination and pollution.

레이저 커팅의 이점

레이저 커터 are primarily used in industrial settings, they are becoming increasingly popular amongst hobbyists due to the numerous advantages they offer. Here we explore how laser cutting benefits both businesses and individuals, with considerations for its environmental impact. For businesses, the most obvious advantage of laser cutting is its speed and accuracy. 레이저 커터 can generate intricate designs quickly and precisely, reducing labor costs while providing consistent quality control across larger batches of products. Furthermore, because these machines use lasers to cut through metal or plastic sheets rather than mechanical means like saws or blades, there’s less scrap waste generated which can be recycled more easily than traditional methods.

Environmental Impact

The environmental impact of laser cutting is an important consideration for businesses and consumers alike. Laser cutting is a technology that has revolutionized the manufacturing industry, providing fast, cost-effective and accurate cutting capabilities across a range of materials. Unfortunately, like many other industrial processes, it can have an adverse effect on the environment if not managed properly. It is therefore essential to consider the potential environmental impact of laser cutting when making any purchasing decisions.

The most significant environmental issue associated with laser cutting rests in its reliance on electrical power. The amount required depends on the size and type of material being cut and thus should be considered when calculating overall energy use. Additionally, hazardous materials such as smoke and dust are generated during laser cutting operations which may need to be collected or reduced using filtration systems if they are not to cause harm to workers or contaminate air quality in surrounding areas.

Sustainable Material Considerations

Sustainable Material Considerations are an important topic when it comes to the use of laser cutting. 레이저 커터 are becoming increasingly popular in a number of industries due to their high precision and accuracy, but they can also have a negative impact on the environment if used without consideration of eco-friendly materials. It is essential to consider sustainable material choices in order to reduce the environmental footprint that comes with using laser cutters. When using 레이저 커팅, materials like wood and metal should be considered first as they are durable and recyclable. Additionally, choosing organic or recycled materials for the production process can help decrease material waste and emissions from manufacturing processes. This can make an impact on reducing the environmental footprint associated with laser cutting technologies. Furthermore, manufacturers should always find ways to minimize energy consumption during production processes by utilizing alternative energy sources such as solar power whenever possible.

Reducing Carbon Footprint

Reducing Carbon Footprint is a major concern for companies and industries today. Laser cutting is an efficient, accurate method of manufacturing that can help reduce environmental impact and increase sustainability in the production process. In this article, we explore the advantages of laser cutting technology and how it can help to reduce carbon emissions, conserve energy, and ultimately protect our planet. The laser cutting process presents many opportunities to cut down on carbon emissions by using less energy than traditional cutting methods such as mechanical saws or grinders. From reduced fuel consumption during transportation of materials to improved quality control through fewer reworks due to precision cuts — laser cutting offers a range of benefits that become even more pronounced when considering its impact on the environment. Additionally, it helps eliminate hazardous waste from machining processes which results in less pollution being released into the atmosphere.

Alternatives to Laser Cutting

Plasma cutting has gained traction in recent years due to its ability to produce clean cuts with minimal waste generation while also consuming less energy than traditional laser systems. Additionally, waterjet cutting, uses pressurized water streams to cut through materials such as metals, plastics and composites with high precision. Waterjet cutting offers many advantages over laser cutting – it does not generate hazardous emissions or fumes, uses significantly less energy compared to lasers and produces little noise during operation. It also has a wider range of material applications than laser cutting, making it suitable for more complex designs and shapes.

결론

The world is becoming increasingly aware of the impact that mankind has on the environment, and as such, businesses have an ever-growing responsibility to consider sustainability in their operations. 레이저 커팅 is no exception; this technology offers a range of advantages over traditional cutting methods, but only when its environmental impacts are managed correctly. This article has explored the potential benefits and costs associated with laser cutting from a sustainability perspective.

Overall, it appears that laser cutting can be an environmentally effective process when used responsibly. Its ability to offer high precision cuts with minimal waste can make it an invaluable tool for reducing energy consumption and environmental footprints in manufacturing processes. However, given the intense energy needs associated with operating lasers, organizations should seek out sustainable sources of power if they are to truly reap the rewards of this technology while meeting their sustainability objectives.