Laser Cutting Machine

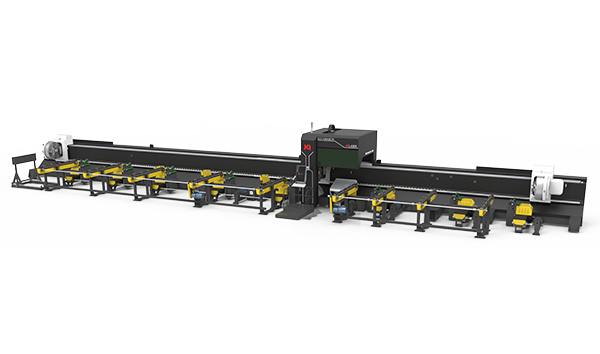

tube laser cutting machine

A laser cutting machine is a device that uses a laser to cut materials. Laser cutting machines are used in a variety of industries, including the automotive, aerospace, and electronics industries. Tube laser cutting machines are especially well-suited for cutting tubes and pipes. Tube laser cutting machines can quickly and efficiently cut tubes to the desired length with a high degree of accuracy. In addition, tube laser cutting machines can cut tubes with complex geometries, such as square or rectangular tubes.Tube laser cutting machines are an essential piece of equipment for many manufacturing operations. If you are considering purchasing a tube laser cutter, there are a few things you should keep in mind. First, you need to determine the type of machine that best suits your needs.

metal laser cutting machine

A metal laser cutting machine is a device that uses a laser beam to cut materials. Metal laser cutting machines are available in a variety of sizes and power levels to suit different needs.Laser cutting is a very precise process and can be used to create complex shapes or patterns. It is also a fast process, which makes it ideal for production work. Metal laser cutting machines are controlled by computer software, which makes them very easy to use.laser cutting machines are much faster than other methods, meaning that large projects can be completed in a shorter time frame. And because there is no need for physical contact between the machine and the material being cut, there is no chance of damage to the material.If you are considering investing in a metal laser cutting machine, then this guide will give you all the information you need to make an informed decision. We will cover the different types of machine available, as well as their key features and benefits.

laser plate cutting machine

A laser plate cutting machine is a device that uses a high-powered laser to cut through metal plates. These machines are typically used in industrial settings, such as factories or warehouses, where they can quickly and efficiently cut through large pieces of metal.Laser plate cutting machines work by focusing a powerful laser beam onto the surface of the metal plate. The heat from the laser beam melts the metal, and the machine’s cutting head then follows the path of the laser to create a clean, precise cut.Laser plate cutting machines can cut through even the thickest metal plates with ease, making them an essential piece of equipment for any business that relies on metal fabrication. If you’re looking for a fast, efficient way to cut through metal plates, a laser plate cutting machine is the perfect solution.

laser welding machine

Laser welding machines have been used in various industries for many years. They are very versatile and can be used for a variety of applications. Laser welding machines are becoming more popular due to their many advantages.The main advantage of laser welding machines is their accuracy. Laser beams are very thin and can be focused on a small area. This makes them ideal for welding delicate parts or components that require precise welds.Another advantage of laser welding machines is their speed. Laser beams can travel at high speeds and they can weld large areas in a short period of time. This makes them much faster than traditional welding methods.Laser welding machines are also very safe to use. The beams are not hot enough to cause any damage to the surrounding area. This makes them ideal for use in areas where there is a risk of fire or explosion.

Unlimited guide of laser cutting machine

Introduction: What Is a Laser Cutting Machine?

A laser cutting machine is a tool that uses a laser to cut materials. The laser cutting machine has a laser beam that is focused on the material to be cut. The laser beam is generated by a laser source, which is then reflected and amplified by a system of mirrors and lenses. The focused laser beam is then used to vaporize or melt the material, which is then blown away by a stream of air or water.

How Does A Laser Cutting Machine Work?

Laser cutting machines are increasingly becoming a more popular option for businesses and consumers who need to make precision cuts in a wide variety of materials. But how exactly do these machines work? Let’s take a look at the basic principles behind laser cutting.

Laser cutting machines work by directing a high-powered laser beam at the material that needs to be cut. The laser beam is generated by a laser resonator, which uses mirrors to amplify the light produced by an electric discharge. The mirrors then direct the beam through a focusing lens, which makes the beam smaller and more concentrated.

When the beam hits the material, it vaporizes it, causing the material to melt, burn, or vaporize. The amount of heat that is generated by the laser can be controlled, which allows for precision cuts. The speed at which the laser moves across the material also affects the quality of the cut.

Laser cutting machines can be used to cut through a variety of different materials, including wood, glass, plastic, and metal. They are often used in industrial applications, but they are also becoming increasingly popular for use in hobby and home projects.

How Many Types of Laser Cutting Machines?

Here we will give a detailed introduction to the types of laser cutting machines on the market:

1. CO2 Laser Cutting Machine

CO2 laser cutting machine is mainly used for non-metal materials, such as wood, acrylic, plexiglass, MDF, plywood, paper, etc.

2. Fiber laser cutting machine

Fiber laser cutting machine is mainly used for metal materials, such as stainless steel, carbon steel, aluminum alloy, etc.

3. YAG Laser Cutting Machine YAG laser cutting machine is an early product and is not very popular now. now it has been replaced by fiber laser cutting machines in many fields.

What Are Laser Cutters Used For?

Laser cutting machines are used in a variety of different industries for a variety of different purposes. They can be used to create anything from car parts to dental implants, and their versatility makes them an essential tool in many factories and workshops.

There are two main types of laser cutter: CO2 and fiber. CO2 laser cutters are the most common type, and they are frequently used to cut metal, wood, and plastic. Fiber laser cutters are less common but they are more powerful and they can be used to cut thicker materials such as metal sheets.

Laser cutters work by directing a high-powered laser beam at the material that needs to be cut. The material is then vaporized or burned away, leaving a clean, precise cut.

What Materials can be Cut with Laser Cutting Systems?

Laser cutting systems can cut a variety of materials, including:

-Metals: aluminum, brass, copper, stainless steel, tool steel, tin

-Thicknesses: thin gauge up to 1″

-Shapes: sheets, tubes, pipes

-Finishes: anodized, powder coated, painted

Technical Parameters of laser cutting machine

1, working area: 1300 * 2500mm

2, laser power: 100W, 130W, 150W, 180W

3, repeatability: 0.02mm

4, positioning accuracy: 0.01mm

5, nc system: DSP off-line control

6, laser type: CO2 gas sealed laser tube

7, min. Line width: 0.1mm (should according to demands of different materials)

8, cutting speed: 0-60000mm / min

9, support graphic format: PLT / DXF / BMP / AI

10, water chiller power: 1P

Pros & Cons of laser cutting machine

Laser cutting machines have become increasingly popular over the past few years, especially in the metal fabrication industry. But what are they? How do they work? And what are the pros and cons of using them?

Laser cutting machines use a high-powered laser to cut through materials. The laser is focused onto a small area of the material, which heats up and melts or vaporizes. The speed and accuracy of laser cutting means that it can be used for a wide range of applications, from cutting sheet metal to intricate designs.

There are many advantages to using laser cutting machines, including:

– They are very precise – Laser cutting machines can cut very intricate designs with a high level of accuracy.

– They are fast – Laser cutting is a quick process, which can be beneficial if you have tight deadlines.

– They are versatile – Laser cutting machines can be used on a variety of materials, including metals, plastics, and wood.

– They are less likely to cause damage – Unlike traditional cutting methods (such as sawing or grinding), laser cutting is much less likely to cause damage to the material or surrounding area.

There are also some disadvantages to using laser cutting machines, including:

– They are expensive – Laser cutting machines can be quite costly, both to purchase and maintain.

– They require skilled operators – Laser cutters require specially trained operators in order to function properly and safely.

How To customize your demand for A Laser Cutter Machine?

As the popularity of laser cutting machines grows, so does the demand for customization. Many companies are now offering laser cutters that can be customized to specific requirements, whether it’s for a certain material or application.

When it comes to customization, there are a few things to consider:

– Material type: What type of material do you want to cut? There are different types of laser cutters that specialize in different materials, so it’s important to choose one that can handle the material you want to work with.

– Cutting speed: How fast do you need the machine to cut? Cutting speed is an important factor to consider, especially if you’re working on a tight deadline.

– Power: How much power do you need? The power of a laser cutter is measured in watts, and the higher the wattage, the more powerful the machine. If you’re looking to cut through thick materials, you’ll need a machine with a higher wattage.

– Size and weight: What are the dimensions of the object you want to cut? The size and weight of the object will determine the size and weight of the machine you need.

– Budget: How much are you willing to spend on a laser cutter? Customization can add up, so it’s important to consider your budget before making any decisions.

How To Choose And Buy An Affordable Laser Cutter?

When you are trying to buy an affordable laser cutter, there are a few things that you should keep in mind. The most important thing is that you need to know what your needs and wants are before you start shopping. If you know what you need and want, then you will be able to find a machine that fits both criteria.

One of the first things that you should do is make a list of all of the features that you would like your machine to have. This list should include things like: power output, speed, work area size, precision, and anything else that you can think of. Once you have this list, you can start looking at different models and brands to see which ones offer the features that you want.

One thing to keep in mind when looking at different models is the price. You don’t want to spend too much money on a machine that doesn’t have all of the features that you want. However, you also don’t want to spend too little money and end up with a machine that doesn’t work well. The best way to find an affordable machine is to look for one that is being offered at a discount. Many companies offer discounts on their products during certain times of the year, so if you can wait for one of these sales, then you will be able to get a great deal on a machine.

Another thing to keep in mind when trying to buy an affordable laser cutter is the warranty. You will want to make sure that the company offers a good warranty on their products. This way, if something does happen to go wrong with your machine, then you will be covered. Most companies offer at least a one-year warranty on their products, but some offer longer warranties for an additional cost.

Finally, when trying to buy an affordable laser cutter, make sure that you take into consideration the shipping cost associated with the purchase. Many times, companies will charge extra for shipping because they have to pay for gas and other expenses associated with getting the product to your doorsteps. However, if you live in an area where there aren’t many shipping options available, then this expense may not be necessary. Just make sure that before finalizing your purchase, find out what the shipping costs are so that there won’t be any surprises down the road after your purchase has been made

How Much Does A Laser Cutter Cost?

The cost of a laser cutter varies depending on the model, power, and features. Lower-end home hobbyist models can be found for around $500, while industrial models can cost upwards of $100,000.

Is A Laser Cutter Worth It?

Like with any machine, the answer to this question is both yes and no. If you have a specific project in mind that requires a laser cutter, then it is definitely worth the investment. However, if you are simply looking for a machine that can do a variety of tasks, then you might want to consider other options.

Here are some things to keep in mind when deciding if a laser cutter is right for you:

-Is the machine going to be used for business or personal use? If you plan on using it for business purposes, then it is definitely worth the investment. However, if you only need it for personal projects, then you might want to reconsider.

-How often do you plan on using the machine? If you only need it for occasional projects, then it might not be worth the initial investment. However, if you plan on using it regularly, then it is definitely worth considering.

-What is your budget? Laser cutters can be quite expensive, so you need to make sure that you have the financial means to support such a purchase.

How To Use A Laser Cutter for Beginners?

Today, we will give beginners a guide on how to use a laser cutter. If you are new to laser cutting, or just want to know more about it, this guide is for you!

First, let’s get familiar with the basics of laser cutting. A laser cutter is a tool that uses a powerful laser to cut through materials. It can cut through wood, plastic, metal, and many other materials. Laser cutters are very precise and can make very intricate cuts.

Now that we know the basics, let’s get started!

The first thing you need to do is decide what material you want to cut. If you’re not sure, that’s okay! There are many different materials that can be cut with a laser cutter. Once you have decided on your material, it’s time to choose the right size for your project.

Next, you need to choose the right settings for your project. This will depend on the material you’re using and the thickness of that material. If you’re not sure what settings to use, don’t worry! There are many resources available that can help you determine the right settings for your project.

Finally, it’s time to start cutting! Place your material in the Laser Cutter and make sure it is secure. Then, select the desired settings and start cutting!

Now that you know how to use a Laser Cutter, there’s no limit to what you can create!

Care & Maintenance of laser cutting machine

As with any machine, proper care and maintenance of your laser cutting machine will help to prolong its lifespan and keep it running at peak performance. Here are a few tips on how to care for your laser:

-Keep the bed and mirrors clean. Wipe down the bed of your machine after each use to remove any dust or debris. Clean the mirrors monthly with a lint-free cloth and Mirrors Cleaning Solution.

-Keep the lens clean. The lens should be cleaned monthly with a Lens Cleaning Solution.

-Calibrate the machine regularly. Most machines need to be calibrated once a week, but consult your user manual for specific instructions.

-Check the alignment of the laser beam regularly. The beam should be aligned with the center of the lens and perpendicular to the surface of the mirror. Check the alignment weekly and adjust as necessary.

Cautions & Warnings for using laser cutting machine

1.Wear proper eye and ear protection. Infrared and ultraviolet light emitted by the laser can be damaging to your eyes, and the noise produced by the laser cutting process can be damaging to your hearing. Be sure to wear proper eye and ear protection when operating a laser cutting machine.

2.Avoid reflected light. Reflected light from the laser beam can be just as harmful as direct exposure to the beam. Be sure to avoid looking at the reflection of the laser beam, and never point the beam at anyone else.

3.Do not touch the Beam. The laser beam is extremely hot and can cause severe burns. Never touch the beam or any objects that have been exposed to the beam.

4.Keep flammable materials away from the machine. The high heat generated by the laser can easily ignite flammable materials, so be sure to keep them away from the machine while it is in use.

5.Never leave the machine unattended while it is in use. If you must leave the area for any reason, be sure to turn off the machine first

Conclusion

When it comes to laser cutting machines, there are many factors to consider before making a purchase. This guide was created to help you understand the different types of machines available and what to look for when choosing one.

There are two main types of laser cutters: CO2 and fiber. CO2 laser cutters are the most common type, and they come in both desktop and industrial sizes. Fiber laser cutters are newer on the market but are quickly becoming popular because they offer a number of advantages over CO2 models, including faster speeds and greater precision.

When choosing a machine, you’ll also need to consider the power (in watts), the bed size (in inches), and the software compatibility. Other factors such as price, support, and warranty should also be considered before making your final decision.

We hope this guide has been helpful in your search for the perfect laser cutter. If you have any further questions, please don’t hesitate to contact us.

explore our insights

Laser Cutting Application in Shipbuilding Boosting Precision, Cost-Efficiency, and Sustainability

The global shipbuilding industry faces three key challenges: shorter delivery cycles, rising material costs, and increasingly stringent environmental regulations. To address these challenges, leading shipyards

Application of laser technology in steel cutting and processing

Laser Technology Principle Laser Generation and Characteristics Laser is a highly coherent and monochromatic light beam generated by stimulated radiation. The generation mechanism of laser

The significance of the plate cutting machine to form complex bevels in one cut

Plate cutting machines have become indispensable tools in modern manufacturing, particularly in industries that require precise and efficient cutting of metal components. One of the