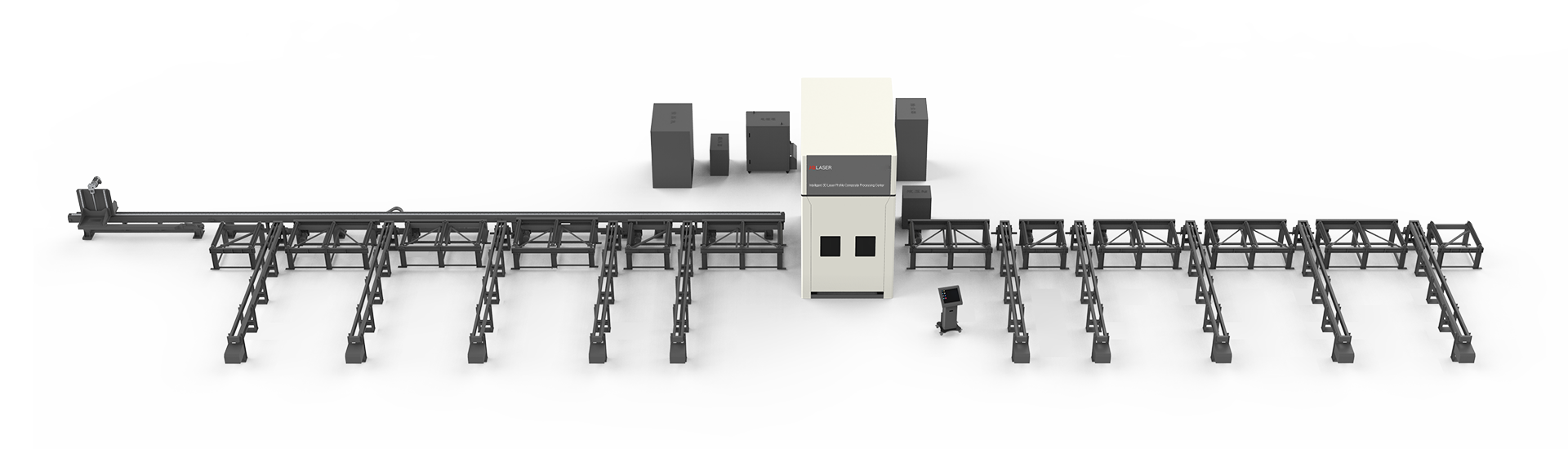

Intelligent 3D Laser Profile composite processing center

Begin on the correct path

H steel, channel steel, angle steel

3D

20000

1000mm*500mm

O melhor da tecnologia no membro mais pequeno da família

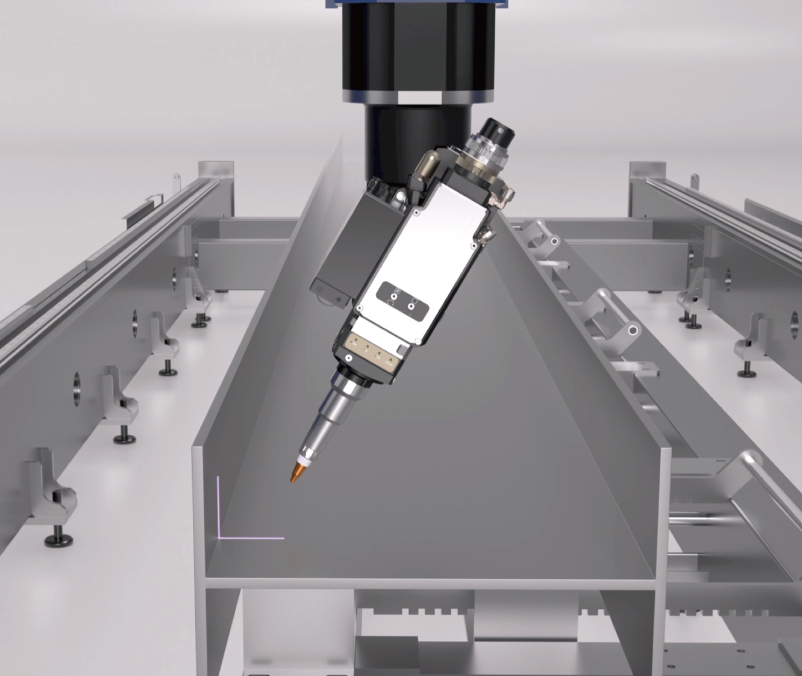

Shape cutting head: 4 series + BC axis + deep finder product portfolio developed for 6~30KW profile cutting applications, air pressure monitoring, lens temperature monitoring, collision prevention and other intelligent technologies are applied. It can meet the processing needs of beam bevel processing, welding notch cutting, bolt hole, etc., and the cutting is stable and the performance is excellent.

Desempenho baseado na robustez e, sobretudo, na fiabilidade.

Ergonómico e acessível

Support multiple automatic loading and unloading, saving labor costs and improving production efficiency.

Automatic loading and unloading of tube up to 20 m in length

Forma e conteúdo numa única solução

As melhores escolhas mostram o seu valor ao longo do tempo

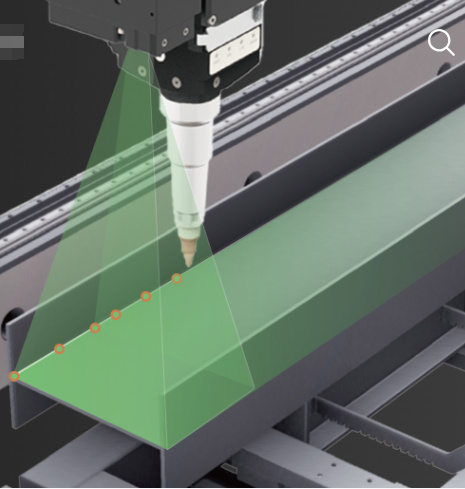

FSCUT’s new profile cutting system FSCUT9200 is equipped with BCW contour scanner. It can effectively detect and compensate for steel deformation types, support various cutting scenarios, and promote the upgrade of production capacity in the steel structure industry through fast graphics and efficient layout.

BCW profile scanner ensures processing precision with real-time measurement and real-time compensation for profile workpiece and drawing deviation. Visually correct.

Correct swing arm model parameters with one click. High accuracy, short time, easy maintenance.

Machine performance will permanecem sólidos, fiável e produtivo ano após ano.

O conjunto de software que cria valor

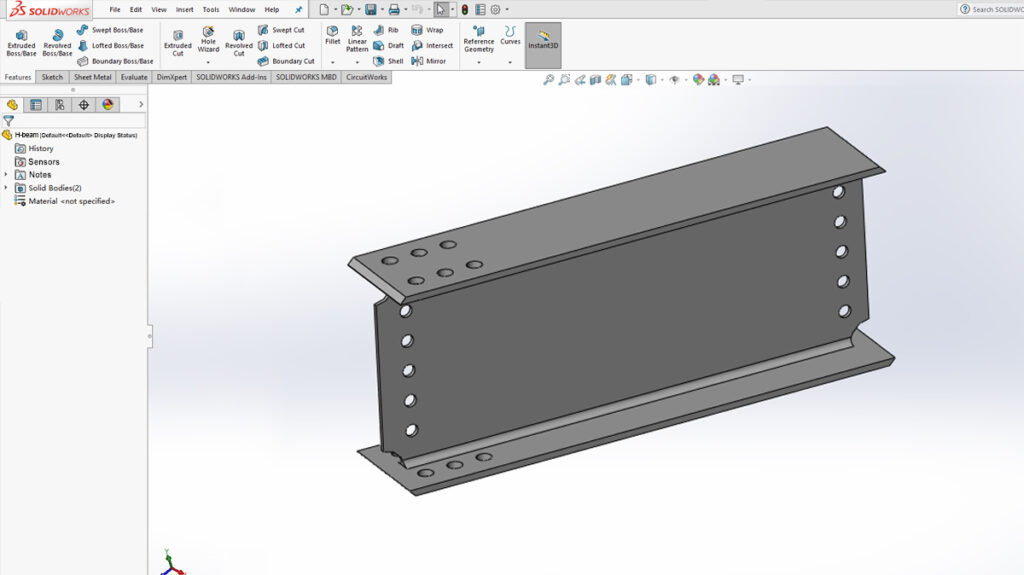

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Lasertubes.

Libraries of functions that speed up and simplify design on the tube.

Estimativas exactas de tempo e custo dos lotes para um orçamento detalhado.

Planeamento remoto e acompanhamento em tempo real dos trabalhos em curso.

Tudo isto e muito mais faz a diferença todos os dias em termos de poder tirar o máximo partido de um sistema de corte a laserreduzindo os tempos de inatividade improdutivos e eliminando o desperdício.

Uma escolha de valor também envolve software.