Introdução

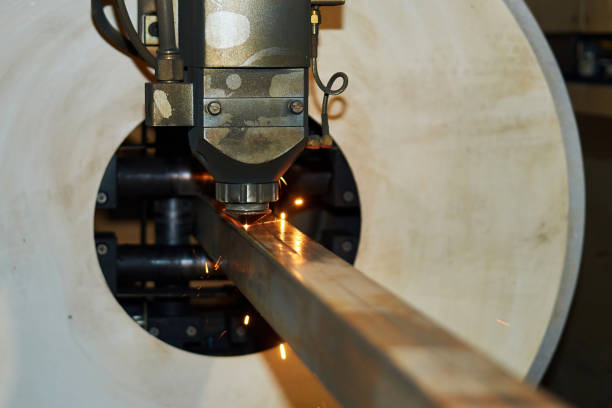

A tube laser cutting machine is a specialized tool used to cut and shape tubes and pipes for a variety of industries. These machines utilize a high-powered laser beam to make precise cuts with a high level of accuracy and speed. In order to achieve the best possible results, it is important to ensure that the machine is properly set up and aligned.

Proper setup and alignment of a tube laser cutting machine can affect the quality of the cuts that are made, as well as the overall efficiency and productivity of the machine. In this outline, we will explore the importance of proper setup and alignment in a tube laser cutting machine, including how it affects the quality of cuts and the factors that can impact proper setup and alignment. We will also discuss the steps that can be taken to ensure proper setup and alignment of the machine.

How proper setup and alignment affect the quality of cuts

Proper setup and alignment of a tube laser cutting machine are crucial for ensuring the quality and accuracy of the cuts that are made. Some of the factors that can impact the quality of cuts include: Laser head alignment: It is important to ensure that the laser head is properly aligned with the cutting area. If the laser head is not aligned correctly, it can result in inaccurate or uneven cuts. Laser beam focus: Adjusting the focus of the laser beam can impact the quality of the cuts. A properly focused beam will result in cleaner, more precise cuts, while an improperly focused beam may result in rough or uneven edges. Cutting speed and power: Setting the correct cutting speed and power is important for ensuring the quality of the cuts. Cutting too slowly can result in rough or uneven edges, while cutting too quickly may result in poor quality cuts or damage to the material being cut. Overall, proper setup and alignment of a tube laser cutting machine are essential for ensuring the quality and accuracy of the cuts that are made.

Factors that can impact proper setup and alignment

There are several factors that can impact the proper setup and alignment of a tube laser cutting machine. These include: Wear and tear on the machine: Over time, the mechanical components of the machine can wear out or become misaligned. This can affect the accuracy and precision of the cuts, and may require regular maintenance and calibration to ensure proper setup and alignment. Changes in material type or thickness: Different materials and thicknesses may require different settings for the laser head, cutting speed, and power. It is important to adjust these settings as needed to ensure proper setup and alignment for the specific material being cut. Changes in ambient temperature and humidity: Changes in the ambient temperature and humidity can impact the accuracy of the cuts and the overall performance of the machine. It is important to monitor these conditions and make adjustments as needed to ensure proper setup and alignment. Overall, it is important to regularly check and adjust the setup and alignment of a tube laser cutting machine to ensure the best possible results.

Steps for ensuring proper setup and alignment

Regular maintenance and calibration: Regular maintenance and calibration of the machine can help to ensure that all of the mechanical components are in good working order and properly aligned. This may include cleaning and lubricating the machine, checking and adjusting the laser head alignment, and testing the accuracy of the cuts. Checking and adjusting the laser head alignment: Regularly checking and adjusting the alignment of the laser head can help to ensure that the cuts are accurate and precise. This may include using specialized tools or software to align the laser head, or manually adjusting the position of the head as needed. Testing cuts on scrap material: Before cutting production parts, it is a good idea to test the setup and alignment of the machine on scrap material. This can help to identify any issues with the setup or alignment and allow for adjustments to be made before beginning production.

Conclusão

In conclusion, proper setup and alignment of a tube laser cutting machine are essential for ensuring the quality and accuracy of the cuts that are made. Proper setup and alignment can affect the quality of the cuts, as well as the overall efficiency and productivity of the machine. There are several factors that can impact proper setup and alignment, including wear and tear on the machine, changes in material type or thickness, and changes in ambient temperature and humidity. By regularly maintaining and calibrating the machine, checking and adjusting the laser head alignment, and testing cuts on scrap material, it is possible to ensure proper setup and alignment and achieve the best possible results.