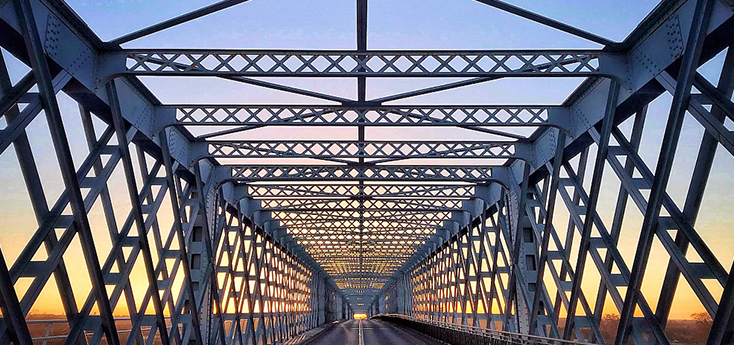

Introduction: How Laser Technology is Revolutionizing Steel Fabrication

The steel fabrication industry is evolving rapidly, thanks to advancements in cutting-edge technology. One such technology is tube laser cutting, which has revolutionized the way steel structures are fabricated. With tube laser cutting, manufacturers can now create accurate and precise cuts on a wide range of steel products of varying thicknesses. This technology has made it possible for manufacturers to fabricate intricate steel structures in record time, with minimal errors and reduced costs.

The Advantages of Tube Laser Cutting for Steel Structures

Tube laser technology offers several advantages over traditional cutting methods. Firstly, it offers high precision and accuracy, ideal for fabricating complex steel structures with intricate cuts. Additionally, tube laser cutting allows for much faster fabrication times compared to traditional methods, ultimately reducing overall costs. Tube laser cutting is also versatile, allowing for the fabrication of a wide range of steel products and parts.

The Applicability of Tube Laser Technology to a Wide Range of Steel Products

Tube laser technology is widely used in the steel fabrication industry, as it offers a variety of benefits when working with different types of steel products. It is particularly useful when working with steel tubes, as it can cut through them rapidly and with incredible precision. Tube laser cutting is also applicable to flat sheets and various other complex structural shapes.

The Precision and Accuracy of Tube Laser Cutting in Steel Fabrication

One of the most significant benefits of tube laser cutting in steel fabrication is its precision and accuracy. The technology uses computer-controlled laser beams to cut through steel tubes and sheets, allowing for incredibly precise and accurate cuts. Unlike traditional cutting methods, there is little room for error, which helps eliminate re-work and waste that increases costs.

The Efficiency of Tube Laser Technology in Saving Time and Reducing Costs

Tube laser cutting has proven to be incredibly efficient when compared to traditional cutting methods. Its accuracy and precision translate into reduced labor costs and waste. Additionally, tube laser technology allows for fast and efficient fabrication times, reducing the overall cost and time to market for fabricated steel products.

The Versatility of Tube Laser Cutting in Designing and Building Steel Structures

The versatility of tube laser cutting makes it ideal for designing and building complex steel structures. The technology can be used to make intricate cuts, such as slots, holes, and other shapes, making it possible to produce structurally sound products in less time. Tube laser technology also allows for the creation of custom designs and profiles, making it easier to create unique steel structures.

Integration into Manufacturing Processes

Manufacturers are increasingly adopting Tube Laser Technology as an integral part of their production processes, streamlining operations and improving overall quality.

Quality Assurance and Precision

The laser technology comes with quality control measures, ensuring that each piece meets strict standards. This eliminates defects and guarantees structural integrity.

The Future of Steel Fabrication with the Integration of Tube Laser Technology

Tube laser cutting is undoubtedly the future of steel fabrication. As the technology becomes more sophisticated, manufacturers will be able to produce even more intricate and precise cuts for a wider range of steel products. The integration of artificial intelligence, automation and robotics in tube laser cutting will further push the boundaries of efficiency and precision.

Conclusion: Why Tube Laser Cutting is the Future of Steel Construction

In conclusion, tube laser cutting technology is a game -changer in the steel fabrication industry. Its high-precision, versatility, speed, and efficiency have made it the industry’s preferred method for making cuts in steel. With its ability to cut through a variety of steel products accurately and quickly, it is no wonder that many steel fabricators are integrating tube laser cutting into their manufacturing processes. In the years to come, we can expect to see even more advancements to make tube laser cutting technology an even more critical part of steel fabrication.