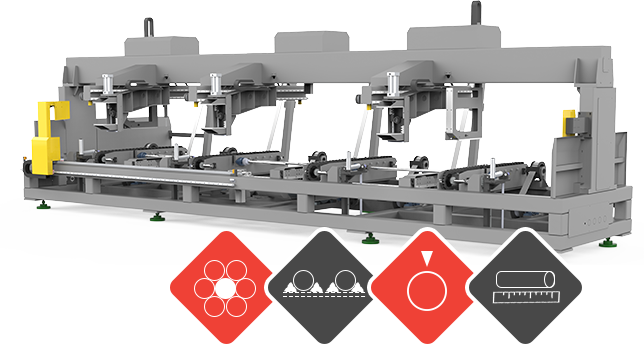

Laser tube technology

Imagine what you can do and do what you can imagine.

With Lasertube, you can make suggestions to your clients in regard to improving part design from the large selection of available incorporated connectors for assembling without screws or welds.

Why choose tube laser

Zero tail material

Three-point clamping for long material cuts, prevents fluttering and guarantees cutting accuracy. Zero tailing is possible when the workpiece length is ≥ 460 mm

·Possibility to set the drawing position for different lengths of parts

·Cyclic drawing is also possible

·Automatic recognition of the lower position

Fast Speed

Precision small chucks

·Rotary motor with 3 kW power

·With helical gearing, the chuck speed is 150 rpm/min

·Up to 200 rpm/min

Wide range of pipe types

·Possibility to set the drawing position for different lengths of parts

·Cyclic drawing is also possible

·Automatic recognition of the lower position

Fully automatic loading

No need for manual

·intervention, saves time and effort

·Automatic loading of short and long materials from 4-6.2M

·20-200dia multi-tube round, square and rectangular tubes

Large load, storage rack with a capacity of 2 tons

100kg for a single tube

Mirror design

Mirror science design

·One person can operate two machines

·Saving customers' labour costs

Technical Parameters Range

| Maximum cutting length | Material 6000-12000mm, unloading piece 0-8000mm |

| Maximum weight for each tube | 4000kg |

| Cutting diameter | 15-650mm O.D. |

| Rotary speed | 60-180rpm |

| X.Y.Z axis position accuracy | ±0.05mm/m |

| Minimum tailing | 0mm |

| Maximum running speed | 100m/min |

| Power supply | 380V/50Hz |

Lasertube, your new competitive edge

Deixe a mensagem e obtenha a resposta

A fim de melhorar a experiência do utilizador e melhorar a nossa tecnologia de produção, a JQ laser tem vindo a recolher perguntas e comentários do mercado sobre o manuseamento de máquinas reais, que iremos analisar e fornecer respostas, e iremos também adotar as ideias de produção favoráveis.