Introduction

When it comes to cutting tube-like materials, many manufacturers are presented with a difficult question: rotary tube cutting or tube laser cutting? Both technologies have their own unique benefits, and the best choice of machine depends on the type of tube cutting project being done. In order to decide between rotary tube cutting vs. tube laser cutting, it is important to understand the advantages of each method, and consider factors such as time, money, precision, operation efficiency, quality of results, repetition gains, maintenance costs, and waste impacts. This article will provide an in-depth comparison of the two tube cutting methods to help those in the industry make an informed decision when selecting a cutting technology for their tube cutting needs.

The Power of Reference: Rotary Tube Cutting vs. Tube Laser Cutting

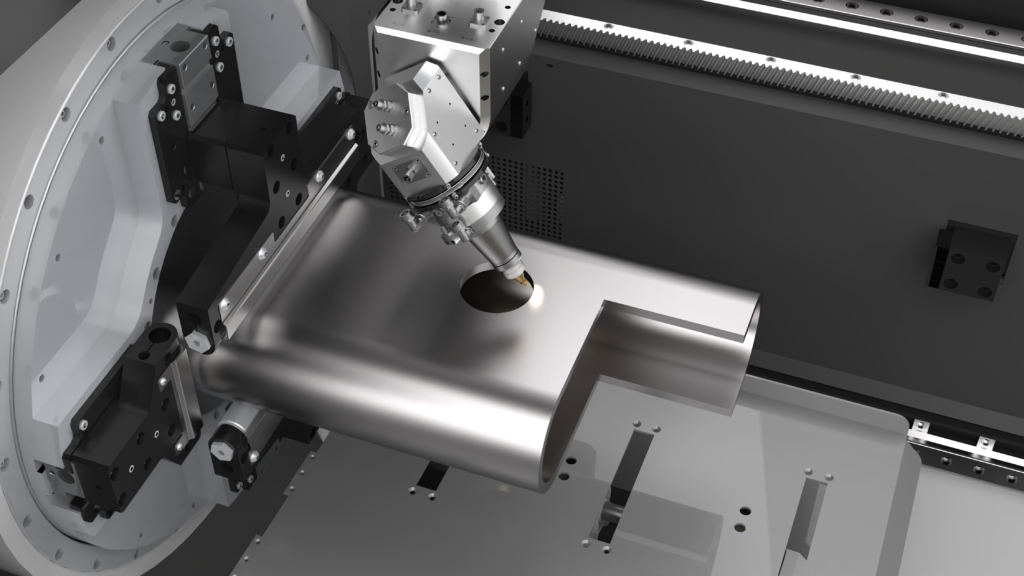

Rotary tube cutting is one of the oldest cutting principles. It is a process that uses a rotating tool to cut a tube material. This tool is typically supported by an X-Y-Z machine table, or a rotary indexer to provide the necessary range of motion for cutting all the angles of a tube material. A major advantage of rotary tube cutting is its long record of demonstrated success. The technology is both reliable and trustworthy, and stable enough to handle many of the latest advancements in cutting technology. Tube laser cutting, on the other hand, uses a laser beam that is directed through the tube to perform accurate and precise cutting. The laser beam is generated by a high power laser source, such as a disk laser, solid-state laser, or fiber laser. This technology is relatively new and advanced, having only been available since the 1990s, but it has quickly become popular as a way to quickly make precise cuts in a wide variety of different materials.

Innovative Options Help you Decide: How Does Each Method Measure Up?

When considering rotary tube cutting vs. tube laser cutting, the question lies in what advantages each technology can offer in terms of time and money. Depending on the size of the project, rotary tube cutting may offer a better return on investment, as the cutting speed is often faster and more cost-effective in the long run. Tube laser cutting can also be a hugely attractive option due to its ability to make more precise and intricate cuts. With the right setup, it is possible to produce more uniform and complex angles that cannot be achieved with a rotary tool. This can be a major benefit for some projects, as the intricate cuts can be achieved quickly and cost-effectively.

Time and Money: Which Process Offers a Better Return on Investment?

When comparing the costs of rotary tube cutting vs. tube laser cutting, it is important to keep in mind the time taken to cut the material. Generally, tube laser cutting is considered to be quicker than rotary cutting when working with smaller parts, while rotary cutting is more cost-effective for larger parts. For smaller parts in particular, tube laser cutting may offer a more desirable return on investment. This is because the cutting speed of a tube laser can be up to five times faster than that of a rotary tool, resulting in less overall time taken to cut the material. On the other hand, when dealing with larger parts the cost of a tube laser may not be worth the time savings, and rotary tube cutting may be the more cost-effective route.

Precision or Proficiency: An Exercise in Exchange?

When it comes to precision, rotary tube cutting traditionally involves the use of a drill bit to make the cut. While this is accurate enough for most standard tube cutting needs, the angle of the cut can sometimes be less precise than would be desired. This is because the drill bit can and will wander off the desired path, resulting in a wider cut and less precise angle. Tube laser cutting, however, can provide a much higher level of precision. The laser beam follows an exact path, providing an accurate and precise cut that can be difficult to attain using rotary tools. It is important to remember though, that this precision comes at a cost; tube laser cutting is often more expensive than rotary tube cutting.

Operating Efficiency: What Manufacturing Goals Will You Achieve?

Rotary tube cutting is relatively slow compared to tube laser cutting, meaning that it is not the best choice when dealing with small parts and intricate cuts that require a high level of precision. With its high speed and higher level of precision, laser cutting can be a more attractive option for manufacturers looking to increase their operating efficiency. On the other hand, rotary tube cutting is still a viable option, particularly when dealing with larger parts. With its lower cost and greater cutting speed, it can be a more cost-effective choice for manufacturers with larger projects, or those who are looking to simply complete a job faster.

Quality of Results: Which Technology Gets the Job Done with Optimal Results?

In terms of the quality of the results, rotary tube cutting is generally considered to be sufficient for standard cutting tasks and it is reliable and a solid choice for many tube cutting needs. However, if precision is the primary goal then tube laser cutting may be the better option. As the laser beam interacts directly with the material to cut, the quality of the cut is a great deal higher when compared to the results obtained using a rotary tool. Ultimately, the quality of the finished result depends largely on the application being undertaken. For instance, if a manufacturer is looking for an accurate and precise cut that also needs to be aesthetically pleasing, then a tube laser may be the better choice.

Repetition Gains: Is Automation the Way to Go?

When it comes to repetition gains, both rotary tube cutting and tube laser cutting can offer significant automation benefits. Rotary tube cutting is typically used in an automated system, with the machine being programmed to be able to consistently cut without operator intervention. Likewise, tube laser cutting can be used in an automated system in order to make cuts with speed and precision. When it comes to automation, rotary tube cutting is the more traditional route and has been around for many decades. Tube laser cutting, on the other hand, is more advanced and is beginning to become more commonplace. The decision between the two largely depends on the type of application and the desired time and cost savings.

Maintenance Costs: What Does Best Practices Mean for Maintenance?

When it comes to maintenance costs, both rotary tube cutting and tube laser cutting are relatively low. Rotary cutting tends to be the most maintenance-free of the two methods, as it generally requires less regular maintenance than laser cutting. Tube laser cutting, however, may require more frequent maintenance due to the use of high-power lasers, meaning regular cleaning, calibrations, and inspections may be needed to keep the machine running at optimal performance.

The Impacts of Waste: What Does Each Process Cost You in Waste?

When it comes to waste impacts, both processes can be efficient and environmentally friendly, depending on the setup. Rotary tube cutting generally produces less waste than laser cutting during production, as there is no need to collect and dispose of the excess material that is produced during the laser cutting process. Tube laser cutting can be more efficient in terms of energy consumption, however, as the laser beam requires less energy to cut than a rotary tool. Depending on the overall process, this efficiency can be a major plus when considering the cost of energy consumed over the life of a project.

Final Reflections: Making the Most Informed Decision on Tube Cutting

While both technologies have their own unique advantages, understanding the comparative advantages of rotary tube cutting vs. tube laser cutting is key to making the most informed decision for your individual project needs. Both processes offer cost effectiveness and precision for various types of tube cutting applications and can be used in various manufacturing environments. Ultimately, the decision of which technology is most suitable should be based on the project requirements, time frame, and budget.

Conclusion

When it comes to tube cutting, rotary tube cutting and tube laser cutting each offer unique advantages. Selecting the right method for the project depends on the scale of the project, the desired precision, and budget considerations. Taking the time to understand the advantages of each technology can help you make the most informed decision when selecting a cutting technology for your tube cutting needs.