- Главная

- Tube Laser Cutting Machine

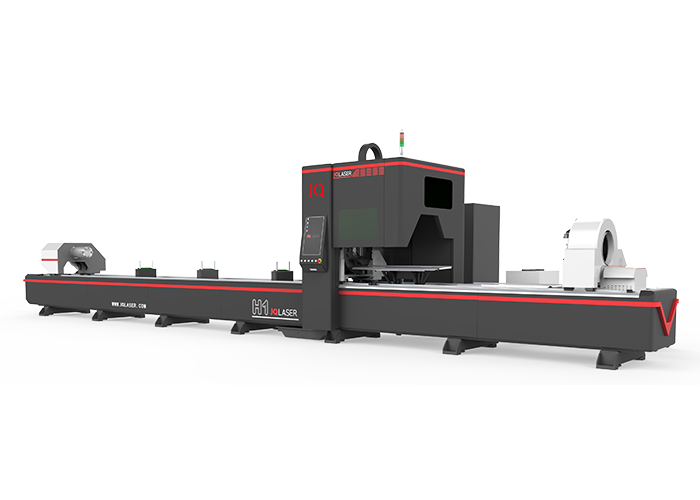

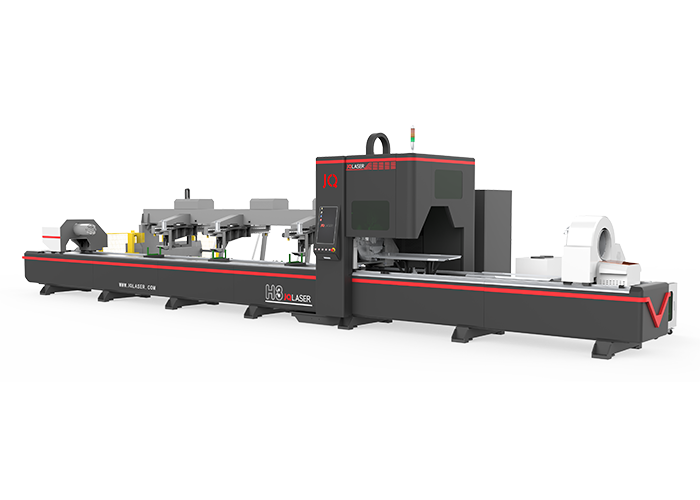

- Heavy Duty Horizontal Three Chucks tube laser cutting machine H1

Heavy Duty Horizontal Three Chucks tube laser cutting machine H1

We produce H1 tube laser cutting machine is a high-quality, versatile machine that can be used for a variety of applications. It is perfect for cutting tubes of all sizes and shapes, and can even be used to cut other materials such as sheet metal and plate.

This machine is built with a heavy duty frame and quality components that ensure years of trouble-free operation. The laser cutting head is precision engineered to provide the highest quality cuts possible.

The H1 tube laser cutter is easy to use, thanks to the intuitive controls and user-friendly interface. Plus, it comes with a comprehensive training manual that will help you get the most out of your machine.

Technical Parameters

| Maximum cutting length | ≤6000mm |

| Maximum weight for each tube | 250kg |

| Cutting diameter | 15-160mm O.D. |

| Rotary speed | 100rpm |

| X.Y.Z axis position accuracy | ±0.05mm/m |

| Minimum tailing | 0mm |

| Maximum running speed | 75m/min |

| Power supply | 380V/50Hz |

Компоненты

Feature

The main use and application scope of the product

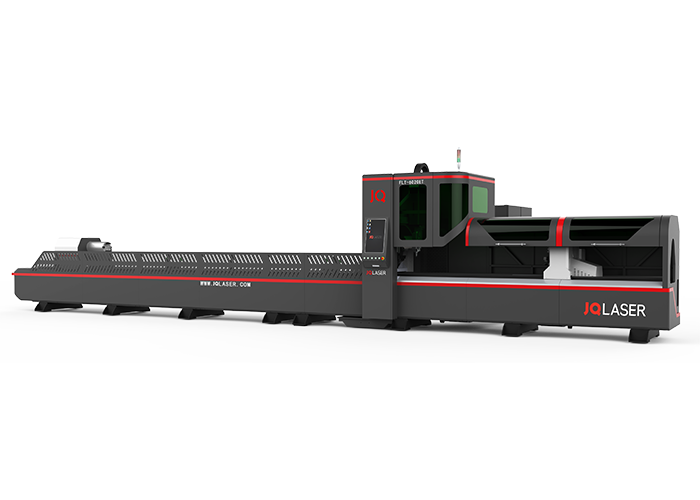

It is mainly used for round, square, rectangular, elliptical and waist round tubes of common carbon steel and stainless steel, etc. The external circle size of cutting workpiece is Φ15-Φ160mm, the length of raw material ranges from 5500 to 6000mm, the loading space is 6500mm, and the discharging space is 3000mm.

The main composition of the product

The main components of FLT-H1 series laser pipe cutting machine are: main machine tool, control system, low voltage electrical system, laser, water chiller, extractor fan, etc.

Основная деталь станка

Machine tool host part is the main component of the whole laser pipe cutting machine, laser pipe cutting machine cutting function and cutting accuracy are achieved by the host part, the host part by the bed, with the support, side column, the chuck part, X / Z axis device, with the material receiving device, auxiliary systems (protective cover, air and water), operation screen and other parts.

Электрическая часть управления

Laser pipe cutting machine electrical control system is to ensure that the various graphics running trajectory of an important part of the general electrical control system is mainly composed of CNC system and low-voltage electrical system.

The machine tool CNC system configuration Bertru high-performance bus type 5000A CNC system, the system is based on windows operating platform, stable and reliable operation, containing 32-bit microprocessor, with nesting software.

Низковольтная электрическая система

The low-voltage electrical system is located in the electric control cabinet, which is the interface part of the electrical control of the whole machine. All the original components of the electrical system are made by famous manufacturers at home and abroad to ensure that the whole machine is stable, reliable and responsive in operation. The drive motor is AC servo motor, AC servo motor is used to drive the X-axis, Y-axis, AW (synchronous rotation) axis of the machine tool, characterized by good acceleration performance, fast response speed, X,Y-axis maximum positioning speed up to 75m/min; machine tool Z-axis for the feed axis, using AC servo motor (with holding brake) for driving: that is, Z-axis cutting head, characterized by good dynamic response characteristics, both with the control and can be NC control.

The fiber laser

The fiber laser used has higher photoelectric conversion efficiency, lower power consumption and better beam quality compared to traditional lasers. The laser is compact, maintenance-free operation and ready for use. Due to its flexible laser output method, it can be easily integrated with system equipment.

2.5 Auxiliary peripherals

Including water chiller, exhaust system, etc.

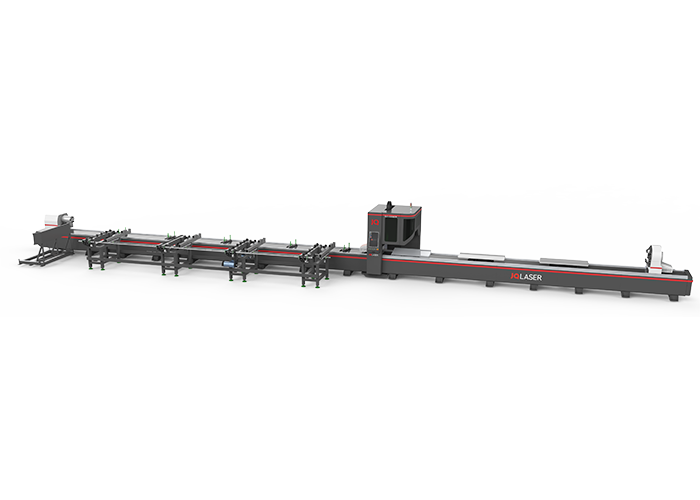

Bed and follower support part

The bed is made of rectangular tube, which is annealed to eliminate internal stress, and finished by vibration aging after rough machining, thus greatly improving the rigidity and stability of the machine, and ensuring the accuracy of the machine. The machine is equipped with automatic lubrication device, which adds lubricating oil to the moving parts of the bed regularly and quantitatively to ensure that the moving parts operate in good condition, which can improve the service life of guide rails, gears and rack.

There are 3 groups of follower support mechanism on the bed, the auxiliary support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), the servo motor drives the up and down movement of the pallet assembly, for rectangular pipes, the system will adjust the pallet height of the pallet assembly in real time according to the outer contour of the pipe to ensure that the pallet supports the pipe stably. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

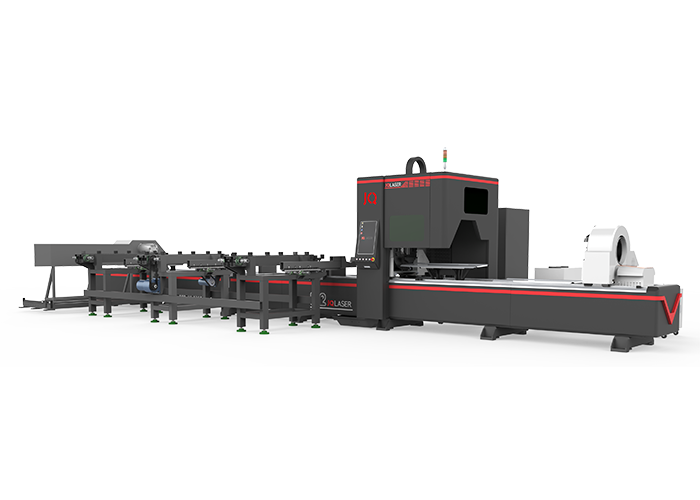

X-axis, Z-axis, side column and chuck section

The side column is fixed on the bed, welded by steel plate as a whole, annealed to eliminate internal stress, rough machining, vibration aging and then finish machining to ensure the rigidity and stability of the moving parts of the laser head.

The X-axis guide adopts servo motor driven gear drive and high quality linear guide to make the Z-axis slide achieve reciprocating motion in X direction. In the process of movement, the limit switch controls the stroke to limit, and at the same time there are elastic cushion mechanical limits at both ends to ensure the safety of the system operation.

Z-axis device is mainly to realize the up and down movement of the laser head. The up and down movement of the laser head is done by the CNC control servo motor driving the linear module to drive the up and down reciprocating movement of the laser head. The upper and lower ends are controlled by proximity switches to ensure the safety and reliability of the movement. The linear modules are all made of high quality products to ensure the accuracy of transmission.

The capacitive sensor in the Z-axis device detects the distance from the nozzle to the surface of the plate and then feeds the signal to the control system, and then the control system controls the Z-axis motor to drive the cutting head up and down, thus controlling the constant distance between the nozzle and the plate and effectively ensuring the cutting quality. The position of the focal point is adjusted according to the material and thickness of the cutting material, thus obtaining a good cutting section. So Z-axis can be used as a CNC axis for interpolation movement with X, Y and W axes, and it can also be switched to follower control to meet the needs of different situations. Since the Z-axis follower is also controlled by the CNC system, the follower has high precision and good stability, thus ensuring the quality of cutting.

Depending on the laser head model, the laser head can be adjusted the focus automatically or manually.

Chuck

The chucks are divided into 3 groups of pneumatic chucks: front, middle and rear, with symmetrical design of rear and front chucks. 3 groups of chucks are driven by servo motors, all of which can move and rotate synchronously in Y-axis direction. Under the logic action set by the system, it can realize the pulling type cutting of the pipe, which can greatly improve the cutting accuracy and can conditionally realize the zero tail material cutting (depending on the workpiece cutting size and specific cutting process).

The Y-axis movement drive rack, linear guide, and W-rotation drive gear are all high precision products, which effectively ensure the accuracy of transmission; each group of chucks is controlled by limit switch and equipped with hard limit device, which effectively ensure the safety of machine movement.

Front pick-up

There are 2 groups of follow-me front pick-up devices. When the cut pipe is long, the plate will hold the pipe to prevent it from sagging. For rectangular pipe, the system will automatically calculate and adjust the height of the splice plate in real time according to the outer contour of the pipe to ensure that the splice plate supports the pipe stably.

According to the length of the workpiece, the system will automatically control the receiving action of 2 groups of receiving devices, i.e. synchronous lifting and turning, and only one of the components can be used for independent action, and the receiving plate can be automatically turned over for unloading, and the position of the lower feed opening can also be used to achieve waste screening, making the machine more intelligent, convenient and efficient.

Electrical control system

FLT-H1 three-chuck pipe cutting machine electrical control system is mainly composed of the bus type system, servo system and low voltage electrical system.

system and low-voltage electrical system.

frequently asked question

Do you have CE? We provide you with CE in the form of a one-stop service. At first, we will demonstrate CE to you. After delivery, we will give you CE packaging list a commercial invoice for customs clearance.

Please tell us about your following answer, our specialist will provide advice on proper power. 1. What material you want to cut, stainless steel, carbon steel or other? 2. What thickness do you want to cut?

If confronted with any problems, please contact us immediately and do not attempt to fix the machine by yourself or anyone else. We will respond within 24 hours as quickly as we can to help you.

2 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Yes, we are happy to provide advice and we have dedicated technicians all around the world who are ready to assist you. Your operations’ continued success relies on your machines staying in working order.

Оставьте сообщение и получите ответ

Для того чтобы улучшить опыт пользователей и усовершенствовать наши производственные технологии, JQ laser собирает реальные вопросы и комментарии по обработке машин с рынка, которые мы будем анализировать и предоставлять ответы, а также мы будем принимать благоприятные производственные идеи.