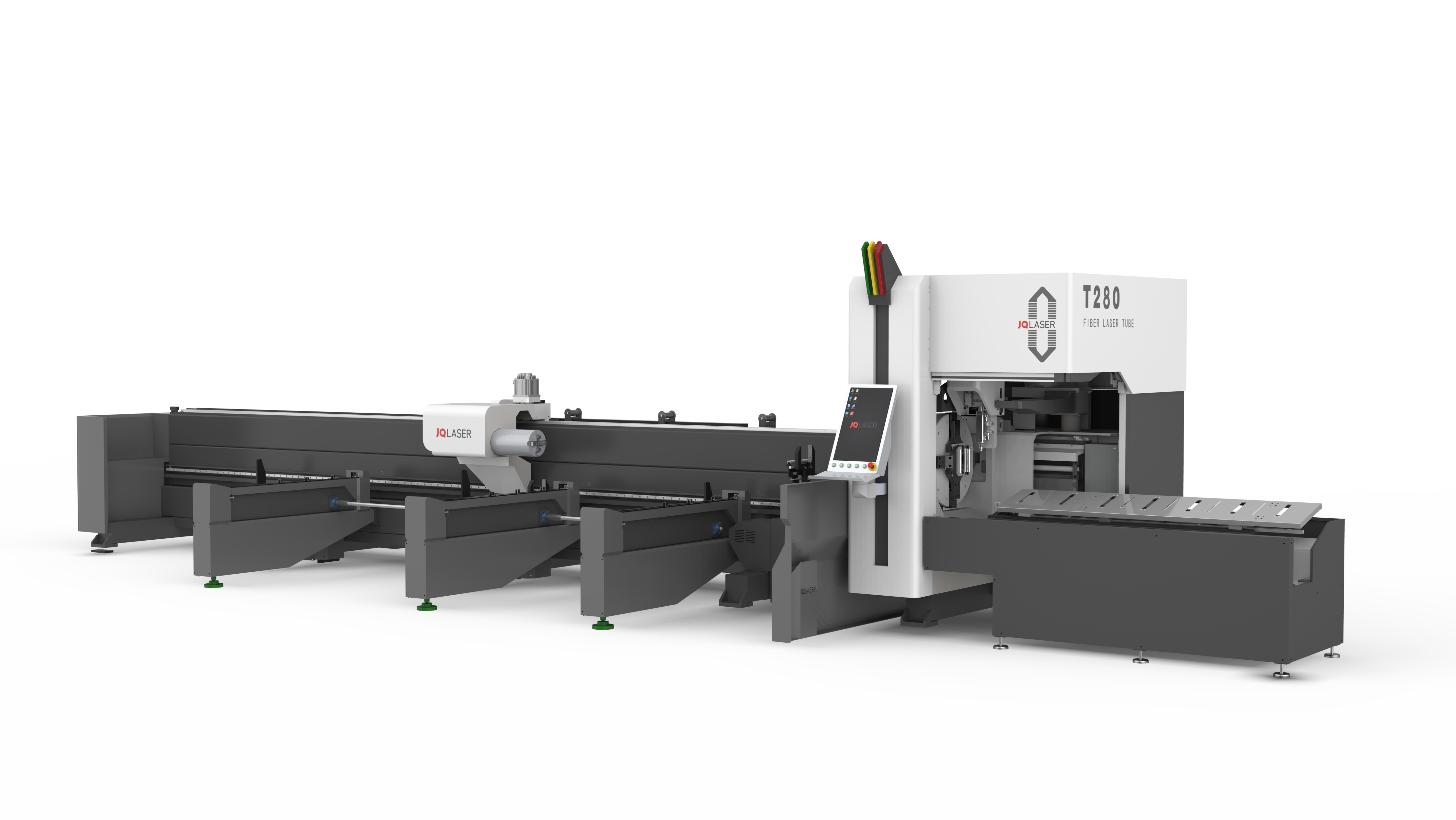

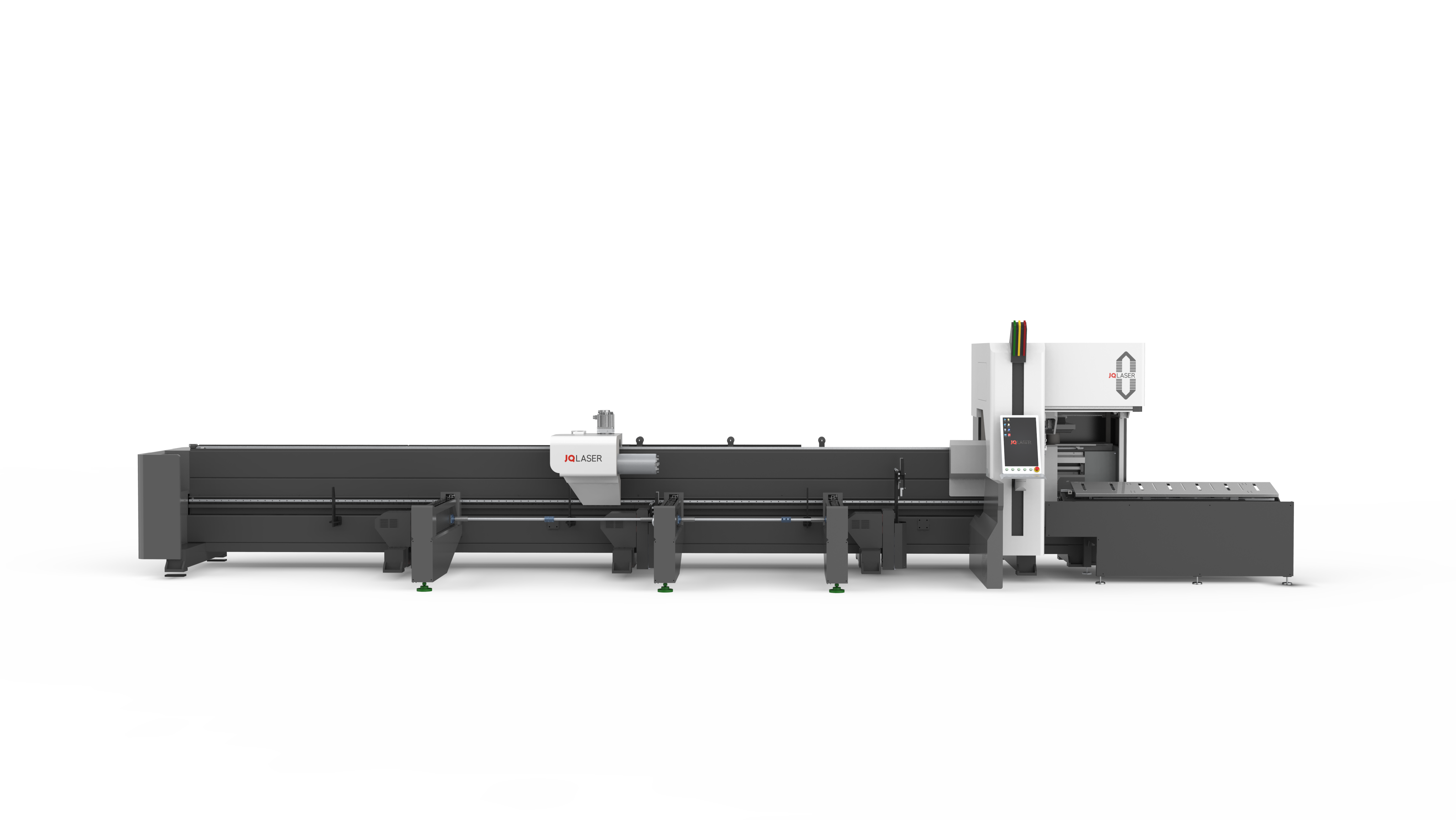

T280

Начните с правильной ноги

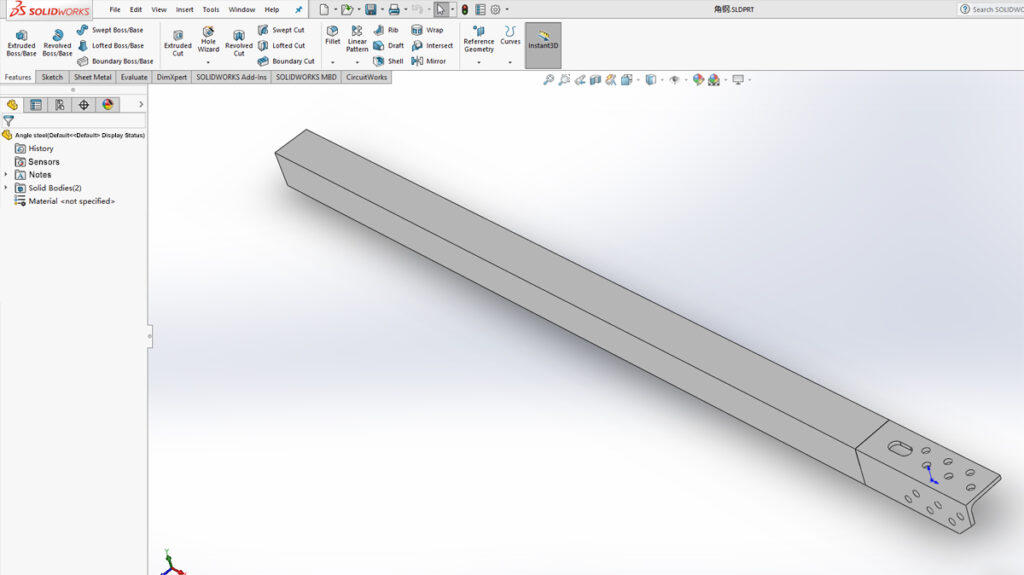

Round, square,

rectangular tubes

3D

400 kg

(15 to 280 mm)

Лучшие технологии в самом маленьком члене семьи

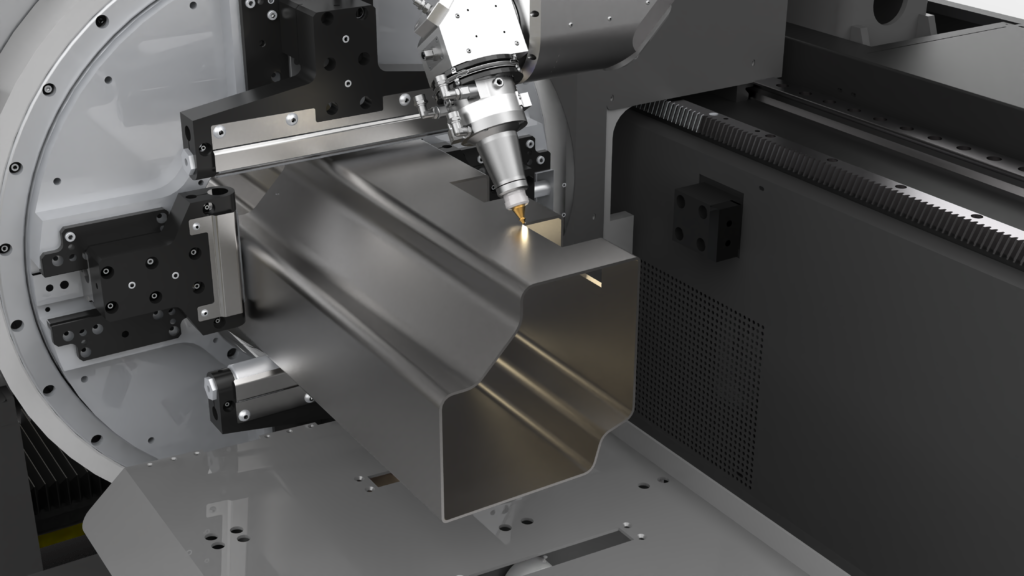

With the new TubeCutter cutting head equipped on the T280, you will produce high quality parts. With automatic focus and integrated laser parameter management, there is no need for adjustments.

Производительность, основанная на прочности и, прежде всего, надежности.

Эргономичный и доступный

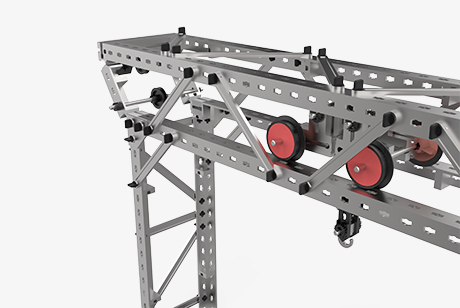

The side-hanging bed features a triangular structure that enhances bed stability. The chuck’s center is positioned outside the main body of the bed, facilitating easier and more convenient loading operations. Additionally, the bed includes a movable front chuck, which ensures stable clamping. This design allows for ultra-short cutting tail material of ≥65mm, resulting in greater material savings.

Form and content in a single solution

Лучший выбор показывает свою ценность с течением времени

Support cutting round, square and shaped pipes with sizes from φ15mm to φ280mm; equipped with semi-automatic loading system, support a variety of pipe types for loading, just place multiple pipes on the conveyor belt to achieve automatic loading

Machine performance will remain robust, reliable and productive year after year.

Программный комплекс, создающий ценность

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Lasertubes.

Libraries of functions that speed up and simplify design on the tube.

Точные расчеты времени и стоимости партии для составления подробной сметы.

Удаленное планирование и мониторинг выполняемых работ в режиме реального времени.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

Выбор стоимости также связан с программным обеспечением.