Введение

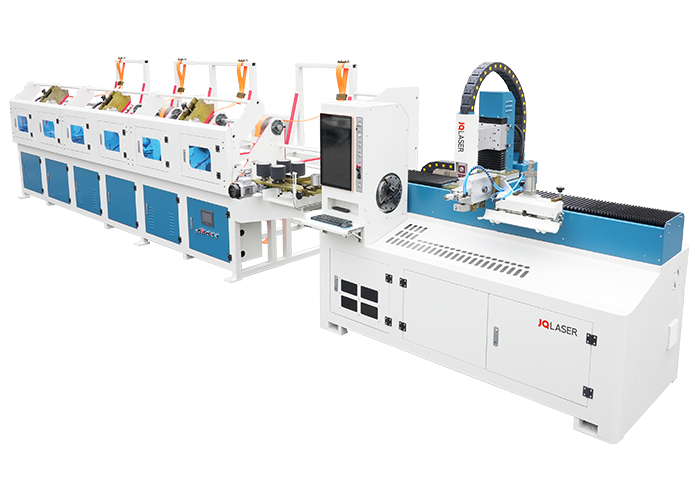

If you’re considering purchasing a laser cutting machine, there are certain things you should know before you make your purchase. Laser cutting is a highly efficient and precise way to cut materials, making it ideal for a variety of applications. However, laser cutting machines can be expensive, so it’s important to understand the different types of machines available and the features that each one offers. This guide will provide an overview of the different types of laser cutting machines, their features, and the advantages and disadvantages of each. It will also discuss the necessary safety measures that should be taken when using a laser cutting machine. Finally, this guide will discuss the cost of laser cutting machines and the different types of materials that can be used with them. By the end of this guide, you should have a better understanding of what to look for when choosing a laser cutting machine.

What Are the Different Software Options for Controlling a Laser Cutting Machine?

Controlling a laser cutting machine requires specialized software to ensure the machine runs smoothly and efficiently. There are several options available, each offering its own features and capabilities.

The first is CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software. This is a powerful program that allows users to create complex designs and then convert them into machine language that the laser cutter can understand. CAD/CAM software is an all-in-one solution for controlling a laser cutting machine and offers a variety of features such as 3D modeling, toolpath generation, and machine simulation.

The second option is CAM (Computer-Aided Manufacturing) software. This type of software is designed to automate the machine setup process and streamline the production process. It offers a range of features such as toolpath generation, feed rate optimization, and cutting speed optimization.

The third option is G-code software. This type of software is specifically designed for controlling laser cutters and is used to generate the G-code instructions that the machine needs to execute its cutting tasks. G-code software is typically used in conjunction with CAD/CAM software to generate the necessary instructions for the machine.

Finally, there is software that specializes in controlling the laser itself. This type of software is used to adjust the laser’s power, focus, and speed. It also allows the user to adjust the parameters of the machine in order to optimize cutting performance.

What Are the Environmental Considerations to Keep in Mind When Purchasing a Laser Cutting Machine?

When purchasing a laser cutting machine, it is important to consider the environmental impact of the machine’s operation. Laser cutting machines are powered by electricity, and their use of energy can have a significant environmental cost. Additionally, the operation of a laser cutting machine can release hazardous gases and particulate matter into the environment.

To minimize the environmental impact of a laser cutting machine, it is important to purchase one that is energy efficient and compliant with local air quality regulations. For example, look for a laser cutting machine that features a built-in dust collection system to reduce the amount of dust and fumes released into the air. Additionally, consider a machine that has a low-wattage laser and a high-efficiency power supply, which will help to reduce energy consumption.

Finally, it is important to consider the disposal of the machine. When a laser cutting machine is no longer in operation, it must be disposed of in an environmentally responsible manner. Look for a machine that is easy to disassemble, so that any hazardous components can be disposed of separately from other materials.

By taking these environmental considerations into account, you can help to ensure that your purchase of a laser cutting machine is as environmentally friendly as possible.

Customer Reviews and Reputation

Before finalizing your purchase, do thorough research on the brand and model you are interested in. Read customer reviews and testimonials to gauge the machine’s performance and the manufacturer’s reliability. A reputable brand with positive feedback is more likely to provide a satisfactory experience.

Warranty and Return Policy

Check the warranty details offered by the manufacturer. A longer warranty period indicates the manufacturer’s confidence in their product’s quality. Also, familiarize yourself with the return policy in case the machine does not meet your expectations.

Exploring the Pros and Cons of Buying a Used Laser Cutting Machine

The advances in laser cutting technology have made it an increasingly popular choice for many businesses. As with any major financial investment, there are advantages and disadvantages to consider when purchasing a used станок лазерной резки.

Плюсы

The primary benefit of buying a used laser cutting machine is the cost savings. Used machines are typically offered at a fraction of the price of a new machine, allowing businesses to save significant amounts of money. Additionally, buying a used machine can be a great way to test out a specific model or brand before committing to a new machine.

Another advantage of purchasing a used станок лазерной резки is the availability of parts and accessories. Used machines have already been tested in the field and accessories such as nozzles, mirrors, and lenses are often readily available, making it easy to maintain and repair the machine.

Cons

The biggest downside to purchasing a used станок лазерной резки is the lack of warranty. Used machines may not have the same level of warranty or support as a new machine, making it difficult to troubleshoot any issues that arise. Additionally, used machines may be more prone to breakdowns, which can be costly to repair.

Finally, the age of the machine should be taken into consideration. Older machines may not be compatible with newer software or hardware, and may not be able to produce the same quality of work as a newer machine.

How to Maintain a Laser Cutting Machine to Ensure Optimal Performance

Maintaining a laser cutting machine is essential to ensure optimal performance and extend its lifespan. To ensure that your machine is running at its best, there are several steps you should take.

First, keep your machine clean. Clean the exterior and interior of the machine regularly, as dust and dirt can damage sensitive components. If the machine has an internal fan, make sure to remove any dust buildup. Also, inspect the mirrors and lenses for any dirt or dust buildup, and clean them with a soft cloth.

Second, inspect the machine regularly. Check for any signs of wear or damage, such as cracks, rust, or frayed wires. Replace any worn or damaged parts immediately. Also, make sure that all of the parts are properly aligned and that all of the screws and bolts are tightened.

Third, check the machine’s optics regularly. Make sure the laser is aligned with the optics, and that the beam is focused properly. If you notice any misalignment, adjust the optics as needed.

Fourth, make sure the machine’s software is up-to-date. Keeping the software up-to-date ensures peak performance, and also reduces the risk of errors or malfunctions.

Finally, follow the manufacturer’s instructions for maintenance and repair. Make sure to keep all of the manufacturer’s manuals and documents in a safe place for easy access.

By following these tips, you can ensure that your станок лазерной резки is running at its best, and that you get the most out of your investment.

Additional Features and Customizations

Some laser cutting machines offer additional features and customizations to enhance their functionality. Explore options like rotary attachments, autofocus systems, and pass-through doors, among others, based on your specific requirements.

Power Consumption

Laser cutting machines can consume significant amounts of power, impacting your operational costs. Evaluate the machine’s power consumption and choose an energy-efficient model to minimize your electricity bills.

Integration with Other Equipment

Consider how well the laser cutting machine integrates with your existing equipment or software. Compatibility with design software and other machinery in your workshop can streamline your workflow and enhance productivity.

What Safety Precautions Should You Take Before Operating a Laser Cutting Machine?

Before operating a laser cutting machine, there are several safety precautions that must be taken.

First, make sure the work area is well-ventilated, as станки лазерной резки produce hazardous fumes and vapors. Wear protective gear, such as safety goggles, safety shoes, and a face shield, to protect against potential laser radiation.

Second, it is important to ensure that all safety devices and interlocks are in place and working properly. Make sure that the machine is properly grounded to prevent potential electric shock.

Third, keep combustible materials, flammable liquids, and other hazardous materials away from the laser cutting machine. Additionally, never leave the machine unattended while it is in use.

Finally, before operating the станок лазерной резки, read the user manual to become familiar with the machine and its safety features. Be sure to follow the instructions and advice provided in the manual.

By taking these safety precautions, you can ensure a safe and successful operation of the laser cutting machine.

Understanding the Different Power Levels of Laser Cutting Machines and What They Mean for You

Understanding the different power levels available is essential for choosing the right machine for your project. The power levels of laser cutting machines vary, depending on the type of material and the thickness of the material being cut. Knowing what power level is needed for your project can help you save time and money.

Laser cutting machines are available in a range of power levels, ranging from 10 watts to 1000 watts. The higher the wattage, the more powerful the machine is and the thicker the material it can cut. Lower wattage machines are used mainly for cutting thin materials, while higher wattage machines are better suited for cutting thicker materials.

For example, a 10-watt machine is ideal for cutting thin materials such as paper, cardboard, leather and fabric. A 20-watt machine is better suited for cutting thin materials such as wood and plastic. A 40-watt machine is ideal for cutting medium-thickness materials such as aluminum and steel. A 100-watt machine is considered a powerful machine and can cut through thicker materials such as stainless steel and titanium.

When choosing a laser cutting machine, it is important to consider the type of material you are cutting and the thickness of the material. If you are cutting thin materials, a lower wattage machine will do the job. If you are cutting thicker materials, a higher wattage machine is recommended.

It is also important to consider the safety features of the laser cutting machine. High-power machines require additional safety measures such as protective glasses, guards and shields. It is also important to consider the size of the work area, as larger machines require more space.

When selecting a laser cutting machine, it is important to take into account the power level, type of material and thickness of the material you are cutting, as well as the safety features available. Knowing what power level is needed for your project can help you save time and money.

What Considerations Should You Make Before Purchasing a Laser Cutting Machine?

Before investing in a laser cutting machine, it is important to consider a number of important factors. First of all, determine what type of materials the machine is designed to cut. Some lasers are designed to cut metal, while others are better suited for cutting wood, plastics, or other materials. Consider the thickness and size of the materials to be cut, as this will influence the type of laser you need.

The power of the laser is also an important factor to consider. The power of the laser determines the speed and precision of the cutting process. Depending on the intended application, you may require a low, medium, or high-power laser.

The accuracy and repeatability of the machine should also be taken into account. Laser cutting machines are designed to produce accurate and consistent cuts, and some models are more accurate than others. For example, some lasers are designed to cut within 0.005 inch of the programmed size, while others are designed to be accurate within 0.001 inch.

Safety is also a very important factor to consider when purchasing a станок лазерной резки. Laser radiation can be hazardous and can cause serious injury or even death if proper safety measures are not taken. Make sure the laser machine you choose is equipped with the necessary safety features, such as a laser interlock system, emergency stop buttons, and so on.

Finally, consider the cost and maintenance requirements of the machine. The cost of the machine will vary depending on the type, power, and accuracy of the laser. The maintenance requirements of the machine must also be taken into account, as some lasers require more frequent maintenance than others.

Заключение

In conclusion, before purchasing a laser cutting machine, buyers should consider their budget, the type of materials that need to be cut, the machine’s power requirements, the available features, and the safety features. Buyers should also ensure that they are buying from a reputable supplier and that the machine comes with a warranty. Taking the time to research and understand the details of станки лазерной резки will help buyers make informed decisions and ensure that they purchase the best machine for their needs.