Laser cutting is a revolutionary process for creating intricate shapes and designs out of wood, fabric, plastics, and other materials. It has become an essential tool for many artisans and makers, allowing them to craft products with unparalleled precision. If you’re curious about laser cutting and want to learn the basics, this article will provide you with some helpful tips and techniques to get started.

Laser Cutting Basics

Laser cutting is a popular and versatile manufacturing process that’s used to cut and shape materials in various industries. It can be used to create intricate shapes, decorative designs, and complex patterns. This article provides an overview of the basics of laser cutting so beginners can confidently get started with this art form. Laser beams are precisely focused onto the material to be cut, creating extreme heat which melts or vaporizes it. The laser beam is controlled by a computer that moves it along the desired path according to programmed instructions. A variety of materials can be cut including metals, plastics, wood, glass and more; making it a very useful tool for artists who want to explore different possibilities with their projects. The laser cutting process requires accuracy and attention to detail so patience is key for beginners trying out this art form.

What Is Laser Cutting?

Laser cutting is a technology that uses laser beams to cut through materials such as wood, metal, and plastic. It is a process that can be used for a wide range of applications from manufacturing to art. With the help of this advanced technology, complex shapes can be cut with precision and accuracy. The process of laser cutting involves focusing the laser on the material in order to vaporize it. The intensity of the laser beam determines how deep or shallow the cuts will be and what type of material will be cut most effectively. This type of cutting has many advantages over traditional methods including faster production time, increased accuracy, minimal waste material, and no need for secondary operations such as sanding or finishing.

Benefits of Laser Cutting

Laser cutting has become an increasingly popular and useful tool for small business owners, artisans, and hobbyists alike. With its precision, affordability, and versatility, laser cutting provides a host of benefits that range from increased efficiency to cost savings. Not only can it be used to create intricate designs with high accuracy and detail, but it also helps reduce waste by only using the exact amount of material needed. When working with a variety of materials such as wood or metal the laser cutter allows users to achieve complex shapes on a wide variety of substrates that would be difficult if not impossible by other methods. Additionally, this method is safer than traditional cutting tools which require physical contact with sharp blades that can cause serious injury.

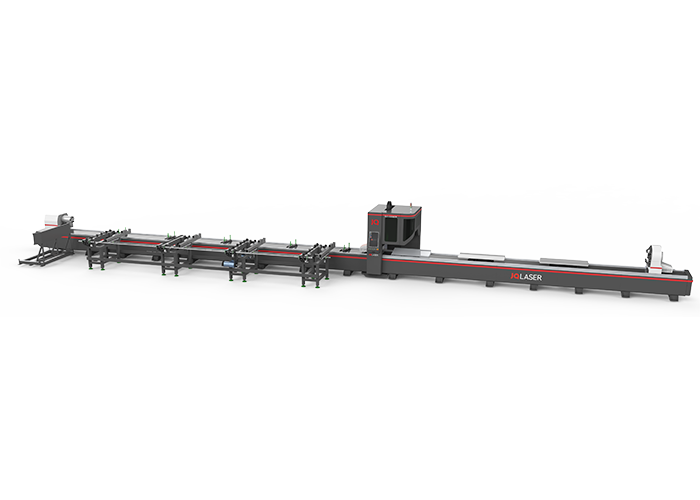

Selecting a Machine

Selecting the right machine can be a daunting task. With so many options available, it is important to consider several factors before making a choice. Cost, size and power are all important considerations when deciding which machine is best for your project. Furthermore, the type of material you plan to cut will also determine what type of machine you need. Before selecting a laser cutter, take some time to research different models and their features. It is essential that you choose a machine with enough power for your project as well as one that fits in with your budget and space requirements. Additionally, make sure that the model you select has an appropriate safety rating for the materials you want to work with and make sure it comes equipped with all necessary tools and accessories for successful use.

Choosing Materials

If you’re just starting out in laser cutting, it’s important to understand the different materials that can be used with the technology. The most common materials used with laser cutters are wood and acrylic, but there are also other options available such as glass, leather, paper, and cardboard. Each material has its own specific properties and capabilities that must be taken into consideration when choosing which material is right for your project.

When selecting a material for laser cutting projects, one of the first factors to consider is power requirements. Different materials require different levels of power and speed for optimal performance. For instance, thicker materials like wood or acrylic will require more powerful lasers than thinner ones like paper or cardboard. Additionally, certain projects may require higher speed settings than others; this should also be taken into account when deciding on a material type.

Tips for Beginners

For those looking to get started in the world of laser cutting and engraving, the process can seem intimidating. But with a little bit of knowledge and practice, anyone can become an expert in this art form! Here are some useful tips and techniques for beginners just getting started with laser cutting.

First, familiarize yourself with the basics of how a laser cutter works. Laser cutters use powerful beams of light to precisely cut out shapes from materials like wood, paper or metal. Understanding this process will help you create more accurate cuts when working on projects. Additionally, it’s important to understand which materials work best for each project; for example, if you’re looking for detailed pieces like etchings then metal may be your best bet.

Techniques to Master

For those just getting started with laser cutting, mastering the technology can be a daunting task. The art of laser cutting requires an understanding of both the software and machine itself, as well as basic design principles. Fortunately, there are tips and techniques that make it easier to become proficient in this skill quickly. From selecting the right materials to properly setting up your workspace and calibrating your laser cutter, all these steps are important for successful results when working with lasers. Additionally, much like any other material-processing process, you’ll need to understand how speed, power level and other factors affect your finished product. For best results, practice makes perfect when using a laser cutter so be sure to experiment with different settings until you find what works best for your project needs.

Conclusion

Laser cutting provides a precise and accurate method of producing intricate shapes and patterns with a wide range of materials. For beginners, understanding the tips and techniques behind laser cutting can be challenging but with practice, anyone can master this useful skill. In conclusion, laser cutting has become an invaluable tool for many different industries such as automotive manufacturing, electronics production, medical device manufacturing and woodworking. With some patience and practice, even beginners can learn how to use this powerful machinery to create incredible works of art from a variety of materials. The tips and techniques outlined in this article provide valuable insight into gaining proficiency in this field so you can start creating amazing pieces right away.