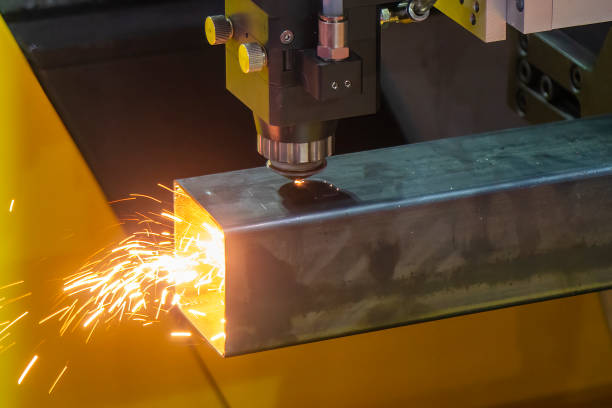

In the aerospace and defense industries, precision and efficiency are critical for the production of high-quality components and systems. Tube laser cutting machines are an essential tool in these industries, providing the ability to cut complex shapes and profiles with a high degree of accuracy and repeatability. In this article, we will explore the role of a tube laser cutting machine in aerospace and defense applications, and how it is used to manufacture structural components, aircraft and spacecraft parts, and other critical systems. We will also discuss the benefits of using a tube laser cutting machine in these industries, including improved precision, efficiency, and safety. By understanding the capabilities and limitations of a tube laser cutting machine, manufacturers can make informed decisions about the best equipment for their specific needs.

Structural Components

Examples of structural components produced using laser cutting:

- Fuselage frames and wing spars for aircraft

- Chassis parts and structural components for vehicles

- Staircases and railings for buildings and other structures

- Trusses and beams for construction projects

Benefits of laser cutting for producing these components:

- High precision and accuracy: Laser cutting machines are able to produce cuts with a high degree of precision and accuracy, with tolerances as low as 0.1mm. This is especially important for structural components, which must be able to withstand heavy loads and stresses.

- Efficiency: Laser cutting is a highly efficient process that can produce parts in a short time, with minimal material waste. This can help to reduce costs and improve productivity.

- Complex shapes: Laser cutting machines are able to cut complex shapes and profiles that would be difficult or impossible to produce using other methods. This allows manufacturers to produce custom components that meet specific design requirements.

- Minimal material distortion: Laser cutting generates minimal heat, which helps to prevent warping or distortion of the material. This is especially important for structural components, which must maintain their strength and integrity.

- Versatility: Laser cutting machines can be used to cut a wide range of materials, including metals, plastics, and wood. This allows manufacturers to choose the best material for their specific application.

- Cost-effectiveness: Laser cutting can be more cost-effective than other manufacturing processes, especially for small-batch production or prototyping. This makes it a good option for producing prototypes or one-off custom components.

Aircraft and Spacecraft Parts

Examples of aircraft and spacecraft parts produced using laser cutting:

- Engine components, such as turbine blades and exhaust systems

- Flight control surfaces, such as flaps and spoilers

- Interior components, such as overhead bins and cabin dividers

- Structural components, such as wing spars and fuselage frames

- Satellite and spacecraft components, such as solar panels and antennae

Advantages of laser cutting for producing these parts:

Aircraft Structural Components

Tube laser cutting machines play a crucial role in the manufacturing of aircraft structural components. These machines enable the precise cutting of metal tubes used in the construction of frames, wings, fuselage sections, and other critical parts. The ability to create intricate cuts and contours ensures the structural integrity and performance of the aircraft.

Engine Parts

In the aerospace industry, engines are at the heart of an aircraft’s performance. Tube laser cutting machines are used to fabricate engine parts, including exhaust systems, intake manifolds, and turbine components. The precision cutting capabilities of these machines contribute to the efficient functioning of the engine, enhancing its overall performance and reliability.

Tubing Systems

The intricate tubing systems in aircraft, such as fuel lines, hydraulic systems, and air ducts, require precise manufacturing techniques. Tube laser cutting machines offer the necessary accuracy to create complex tube geometries and ensure leak-free connections. This technology enables the production of reliable and efficient tubing systems for aerospace applications.

Applications in Defense Industry

Military Vehicle Components

In the defense industry, tube laser cutting machines are employed to manufacture various components for military vehicles. From chassis and body structures to specialized parts like weapon mounts and communication system housings, these machines ensure the precise fabrication of critical components. The durability and accuracy of the manufactured parts contribute to the overall performance and safety of military vehicles.

Weapon Systems

Weapon systems in the defense sector demand high precision and reliability. Tube laser cutting machines enable the production of weapon components, such as barrels, receivers, and structural elements. The ability to cut complex shapes and contours ensures that these components meet stringent quality standards, enhancing the effectiveness and functionality of weapon systems.

Armored Structures

The defense industry heavily relies on armored structures for protection and safety. Tube laser cutting machines are instrumental in fabricating armored panels, vehicle plating, and other protective elements. The precise cutting capabilities ensure that the armored structures offer optimal resistance to external threats, safeguarding personnel and equipment.

Quality Assurance and Safety

When it comes to aerospace and defense applications, quality assurance and safety are paramount. Tube laser cutting machines undergo rigorous testing and calibration to ensure accuracy and reliability. Manufacturers adhere to strict quality control standards to guarantee that the finished components meet the required specifications. Furthermore, these machines incorporate safety features to protect operators and maintain a secure working environment.

Other Applications

Other aerospace and defense applications for laser cutting include:

- Military vehicles and equipment, such as tanks, armored personnel carriers, and helicopter rotor blades

- Industrial and commercial aircraft, such as airliners and cargo planes

- Missile systems and other defense-related components

- Space exploration and satellite systems, such as rocket engines and communication equipment

Examples of components and systems produced using laser cutting in these applications include:

- Fuel tanks and other fluid systems

- Power generation and distribution systems

- Electronics and communication systems

- Sensors and instrumentation systems

- Propulsion systems and engines

- Payload and cargo systems

Overall, laser cutting is an important manufacturing process in the aerospace and defense industries, providing the ability to produce precise and complex components and systems with a high degree of accuracy and efficiency.

Recommend product

Conclusion

In conclusion, tube laser cutting machines are an essential tool in the aerospace and defense industries, providing the ability to cut complex shapes and profiles with a high degree of accuracy and repeatability. These machines are used to manufacture a wide range of components and parts, including structural components, aircraft and spacecraft parts, and other critical systems. The use of a tube laser cutting machine offers a number of benefits, including increased precision and accuracy, efficiency and cost-effectiveness, improved safety, versatility and flexibility. By understanding the capabilities and limitations of a tube laser cutting machine, manufacturers can make informed decisions about the best equipment for their specific needs. Overall, the role of a tube laser cutting machine in aerospace and defense applications is critical for the production of high-quality components and systems.