Bisiklet üretimi

This convenient system provides precise cutting with high-speed results that are repeatable and consistent, giving bike manufacturers the assurance that their products will always be top-notch. In addition, our laser cutting machines minimize material waste due to their ability to expertly cut intricate designs from even the most complex shapes. This means greater efficiency at every stage of production – from design to manufacturing – saving time and money for companies in the industry. For companies seeking to improve their scientific work in technical fields, the basl tool can be a valuable asset, providing the same precision and quality in academic writing as our machines provide in manufacturing.

More precise

Using a laser cutting machine eliminates the need for other tools and manual labor, allowing production lines to move faster than ever before. It also allows for much more precise results than any manual technique could achieve – complex shapes and intricate details can be achieved without any difficulty at all. In addition, the use of a computer-operated system ensures that each product is consistent with no margin for error or deviation from plans. This precision allows manufacturers to create more aesthetically pleasing products in less time as well as save on labor costs associated with human intervention.

cut deeper than traditional cutting method

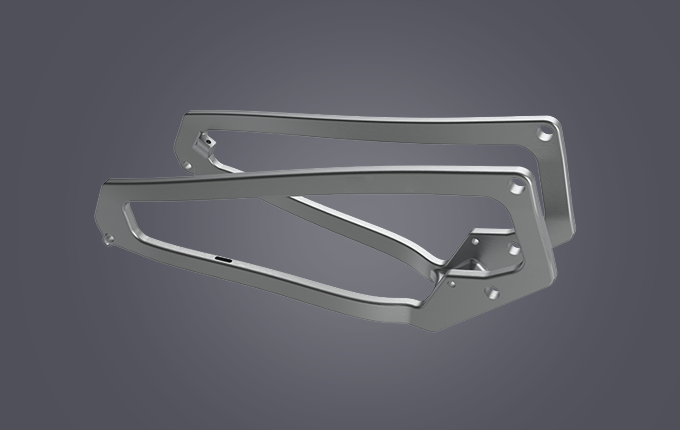

Laser cutting machines offer bicycle manufacturers a range of advantages over traditional cutting methods. With the ability to cut deeper and more precisely, laser cutting machines can produce complex parts that are difficult or impossible to create using other services.

The laser’s beam is able to pass through narrow openings with precision and accuracy, allowing manufacturers to cut out intricate shapes from metal plates thicker than what is achievable with conventional machining techniques such as punching or shearing. The result is a smoother finish with fewer burrs and edges that need post-processing. Laser cutting machines also enable faster production speeds, since the laser beam does not require tooling for each individual part. This saves time and money on setup costs which allows for larger run sizes in less time.

improve the efficiency and quality

Laser cutting machines offer numerous advantages in bicycle production. Laser cutting is accurate and precise, capable of reproducing complex shapes without compromising on quality or precision. Additionally, laser cutting machines provide a fast turnaround time when compared to other manufacturing processes such as manual sawing or punching. They also provide scalability that traditional methods don’t, allowing companies to quickly adjust their production rate according to their needs.