- Ev

- Plate Laser Cutting Machine

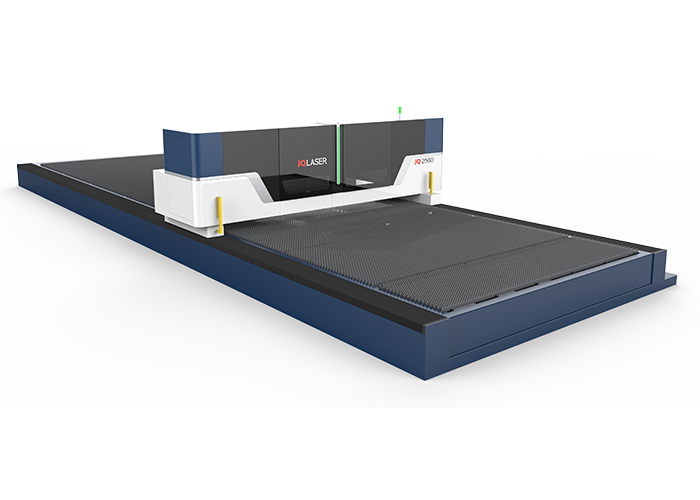

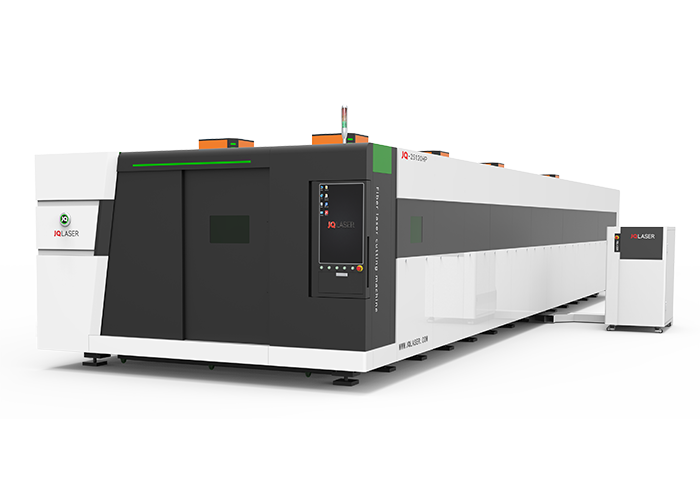

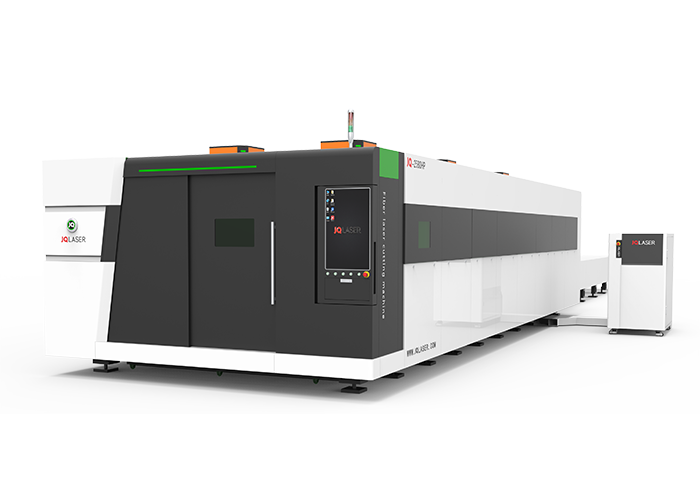

- Ground Rail Type High Power Laser Plate Cutting Machine JQ 2560

Ground Rail Type High Power Laser Plate Cutting Machine

JQ 2560/25120/3560/35120/35240/60240

Ground rail type high power laser plate cutting machine JQ-2560 is a reliable and efficient cutting solution for businesses looking to take their production processes to the next level. This advanced machine offers unparalleled precision, speed and accuracy while allowing users to achieve intricate cutting patterns with extreme precision. It features an innovative ground rail design that ensures maximum stability during operation, making it ideal for large projects requiring complex designs or shapes.

Technical Parameters

| Working table for straight cutting | 2500*6000mm,2500*12000mm,3500*6000mm,3500*12000mm,3500*24000mm,6000*24000mm |

| Working area for bevel cutting | 1900*5400mm,1900*11400mm,2900*5400mm,2900*11400mm,2900*23400mm,5400*23400mm |

| Positioning accuracy | 0.05mm |

| Repositioning accuracy | 0.03mm |

| Max. moving speed | 80m/min |

| X .Y maximum acceleration | 1G |

| Z axis maximum speed | 40m/min |

| Laser source | Raycus |

| Laser source power | 6KW |

| laser head | Raytools |

| Anti-slag protection function of double cyclones | ● |

| X-axis、Y-axis、Z-axis | Yaskawa 4.9kw |

| Servo motor and driver | |

| Slideway | THK |

| Rack | YYC |

| Reducer | Japan SHIMPO |

| Automatic lubrication function | ● |

| Control system | FSCUT 8000 |

| Cutting gas automatic pressure regulation function | N2,O2 |

| Breaker | France Schneider |

| Relay | France Schneider |

| System identification file format | IGS、DXF |

| Dust removal | Centrifugal fan |

| Total power with 15 KW laser source | 60KW |

| Machine suitable for voltage as | 380V,50Hz,3phases. |

| Maximum weight of load capacity | 5000KG |

Bileşenler

Feature

■Gantry + floor rail bed machine base.

■Raycus laser source.

■Raytools Laser head with with bevel cutting

■FSCUT8000 controller.

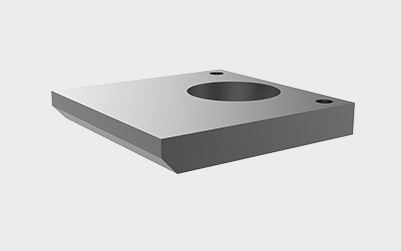

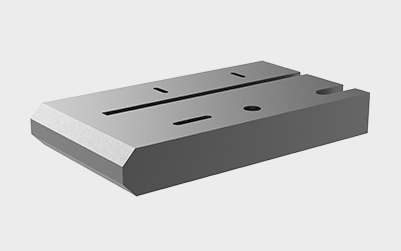

Machine base introduce

Segmented bed design, length can be customized, greatly reducing transportation costs

Sectional modular workbench, convenient for customers to replace, improve cleaning and maintenance efficiency, facilitate transportation, reduce maintenance costs and transportation costs

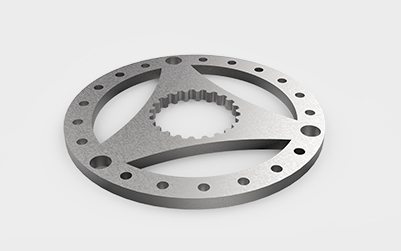

Bevel cutting

The bevel cutting head with Raytools(optional Precitech) laser head can achieve 0-45 ° groove cutting, and support V, Y, K, X and gradual groove cutting technology .

Raycus laser source

The multi-module continuous fiber laser series developed raycus Laser covers products between 6000W and 30kW. It has high electro-optical conversion efficiency, good beam quality, high energy density, wide modulation frequency, high reliability, long life and maintenance-free operation. And so on, can be widely used in welding, precision cutting, cladding, surface treatment, 3D printing and other fields. Its fiber output features make it easier to integrate with robots into flexible manufacturing equipment to meet the needs of 3D machining.

Hanli Water Chiller

When laser head cut metals, there will produce some hot energy in laser head and laser device. Water chiller is for cooling this two parts. Laser head part, mainly cooling the mirrors.

Temperature in the water chiller is auto adjustment, mainly set up with 25 degree around.

Water in chiller should be pure water. (one week change one time)

Exhaust system solution

The left blowing and right suction exhaust design fully solves the problem of smoking in large format, the direction of the exhaust system can be designed according to customer requirements.

Zonal ventilation design can increase smoking pressure

protection solution for bevel cutting – Safety grating

frequently asked question

Do you have CE? We provide you with CE in the form of a one-stop service. At first, we will demonstrate CE to you. After delivery, we will give you CE packaging list a commercial invoice for customs clearance.

Please tell us about your following answer, our specialist will provide advice on proper power. 1. What material you want to cut, stainless steel, carbon steel or other? 2. What thickness do you want to cut?

If confronted with any problems, please contact us immediately and do not attempt to fix the machine by yourself or anyone else. We will respond within 24 hours as quickly as we can to help you.

2 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Yes, we are happy to provide advice and we have dedicated technicians all around the world who are ready to assist you. Your operations’ continued success relies on your machines staying in working order.

Mesaj Bırakın ve Cevabı Alın

Kullanıcı deneyimini iyileştirmek ve üretim teknolojimizi geliştirmek için JQ lazer, piyasadan analiz edeceğimiz ve cevap vereceğimiz gerçek makine işleme sorularını ve yorumlarını toplamaktadır ve ayrıca uygun üretim fikirlerini benimseyeceğiz.