Giriş

The construction industry is a major contributor to the global economy, with a wide range of businesses and workers involved in the planning, design, and building of infrastructure, buildings, and other structures. This includes architects, engineers, construction managers, contractors, and a variety of tradespeople, such as electricians, plumbers, and carpenters.

Construction projects can range from small renovations to large-scale commercial and residential developments, and may involve the construction of new buildings or the renovation and expansion of existing ones. The construction industry is constantly evolving, with new technologies and techniques being developed and implemented to improve efficiency, safety, and sustainability.

In order to complete these projects, construction professionals rely on a variety of tools and equipment, including heavy machinery, hand tools, and specialized equipment such as tube laser cutting machines. By utilizing these tools and technologies, construction professionals are able to effectively plan and execute projects, meeting the needs of their clients and stakeholders.

How a tube laser cutting machine is used in the construction industry

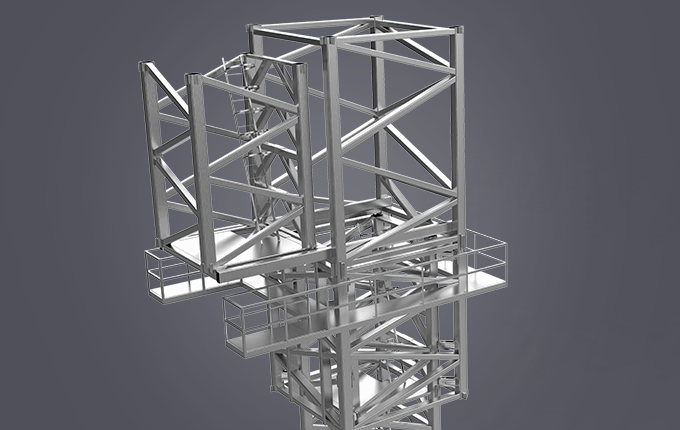

In the construction industry, a tube laser cutting machine is primarily used for cutting and shaping tubes and pipes for use in building structures. These machines are able to make precise cuts with a high level of accuracy, which is crucial for ensuring that the structural elements of a building fit together properly and are able to support the loads they will be subjected to.

In addition to cutting tubes and pipes, a tube laser cutting machine can also be used to create precise cuts for welding and assembly. These machines are able to make cuts with a high level of precision, which can improve the overall quality and accuracy of the welded joint. This can be especially important for critical structural elements that must be able to withstand high loads or forces.

Another benefit of using a tube laser cutting machine in the construction industry is the ability to significantly reduce the time and labor needed for cutting tasks. These machines are able to make cuts quickly and accurately, which can save time and labor compared to traditional cutting methods. This can help to reduce the overall cost and duration of a construction project, and can also improve safety by reducing the amount of time that workers need to spend performing manual cutting tasks.

Advantages of using a tube laser cutting machine in the construction industry

There are several advantages to using a tube laser cutting machine in the construction industry: Increased accuracy and precision in cuts: One of the main advantages of using a tube laser cutting machine is the ability to make precise cuts with a high level of accuracy. This is especially important for structural elements that must fit together properly and be able to withstand high loads or forces. Increased efficiency and speed of production: These machines are able to make cuts quickly and accurately, which can save time and labor compared to traditional cutting methods. This can help to reduce the overall cost and duration of a construction project. Ability to cut a variety of materials: Tube laser cutting machines are able to cut a wide range of materials, including metals and alloys. This versatility makes them useful for a variety of construction projects, as they can be used to cut the materials needed for a particular project. Reduced material waste and cost savings: These machines are able to make precise cuts with minimal waste, which can help to reduce the overall cost of a project. In addition, the ability to make precise cuts can help to reduce the amount of material needed for a project, further lowering costs.

Challenges and limitations of using a tube laser cutting machine in the construction industry

There are also some challenges and limitations to using a tube laser cutting machine in the construction industry: Initial cost of purchasing and maintaining the machine: These machines can be expensive to purchase and maintain, which may be a challenge for some construction companies. Need for skilled operators: These machines require trained operators to operate them safely and effectively. This can be a challenge for construction companies that do not have trained staff or that need to train new employees on the use of the machine. Limited ability to cut thick or highly reflective materials: Tube laser cutting machines may have limitations when it comes to cutting thick or highly reflective materials. This can be a challenge for construction projects that require the use of these materials.

Sonuç

In conclusion, the role of a tube laser cutting machine in the construction industry is crucial for increasing accuracy, efficiency, and cost-effectiveness in the production of building materials. These machines are able to make precise cuts with a high level of accuracy, which is essential for ensuring that structural elements fit together properly and are able to withstand the loads they will be subjected to. In addition, the ability to make cuts quickly and accurately can help to reduce the time and labor needed for cutting tasks, saving time and money on construction projects.

However, it is important to consider the challenges and limitations of using a tube laser cutting machine, including the initial cost of purchasing and maintaining the machine, the need for skilled operators, and the limited ability to cut thick or highly reflective materials. By understanding the capabilities and limitations of this technology, construction professionals can make informed decisions about how to best utilize it in their projects.