Introduction

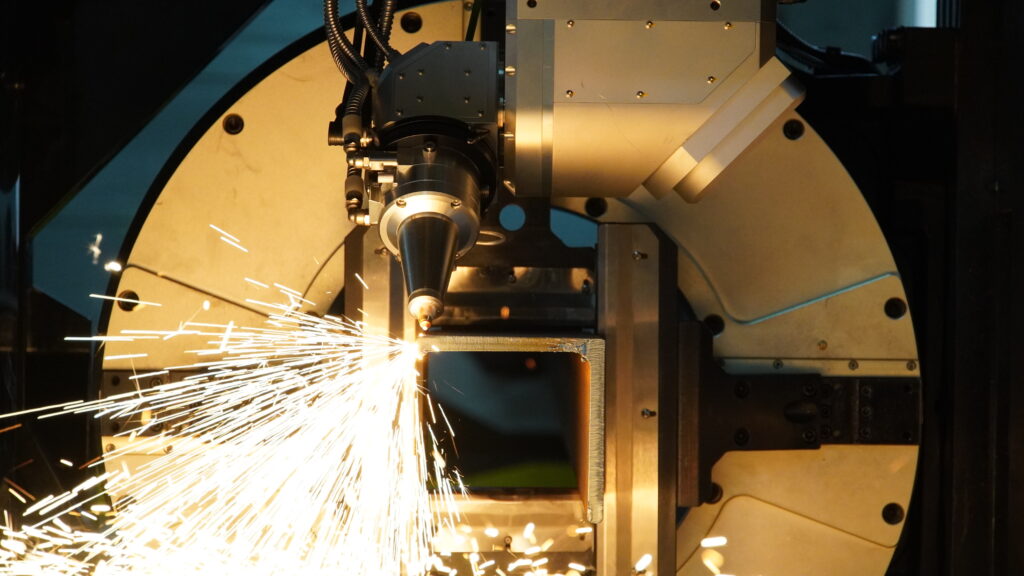

The introduction of tube laser cutting technology has revolutionized the way we fabricate components with CNC machines. With the ability to cut metals and other materials with accuracy and speed, this technology has opened up numerous new possibilities for the creation of complex components. With its laser cutting capabilities, tube laser cutting technology brings a new level of efficiency and accuracy to CNC machining, allowing for the creation of components with unprecedented precision. Read on to learn more about the potential of tube laser cutting and how it can help to unlock new possibilities in the realm of CNC machining.

Unlocking the Power of Tube Laser Cutting

Tube laser cutting technology is capable of cutting through a range of materials with remarkable accuracy and speed, making it the perfect choice for high-precision applications in the metal fabrication sector. Tube laser cutting uses a concentrated beam of light that can be programmed to the required shape and strength to perfectly cut through any type of metal or material. This laser cutting technology is particularly popular for producing complex components and shapes that would otherwise be difficult to create with traditional CNC cutting processes.

Exploring the Potentialities of Tube Laser Cutting

Tube laser cutting is incredibly versatile, enabling manufacturers to quickly and accurately cut components from a wide range of materials. This precision cutting technology can be used to create complex shapes and components that are difficult to manufacture with other CNC cutting methods. Laser cutting also requires fewer setup steps and less labor than traditional machining techniques, leading to reduced costs and improved efficiency.

Discovering New Worlds of Possibilities with Tube Laser Cutting

The introduction of tube laser cutting has opened the door to the discovery of countless new possibilities. This technology can be used to create components with intricate details, sharp edges, and complex shapes. The accuracy and precision of tube laser cutting makes it perfect for producing components with intricate geometries, complex internal cavities, and long life-cycles. This technology can even be used for intricate assembly components, eliminating the need for expensive welds and other labor-intensive processes.

Tube Laser Cutting: A Revolution in CNC Machining

Tube laser cutting has brought about a revolution in the world of CNC machining. By utilizing this cutting-edge technology, manufacturers can produce components with unprecedented accuracy and speed. This technology is also incredibly reliable and long-lasting, allowing for components to be produced more quickly and cost-effectively. The advantages of tube laser cutting cannot be denied and it is becoming an increasingly important part of the manufacturing process.

Advantages of Tube Laser Cutting

The adoption of tube laser cutting technology brings forth a plethora of advantages that have revolutionized the manufacturing process.

1. Precision and Accuracy

One of the standout features of tube laser cutting is its remarkable precision. It can create intricate cuts with minimal material wastage, making it an excellent choice for industries where every millimeter counts.

2. Versatility

Tube laser cutting is not limited to a single material or application. It can effortlessly handle a wide range of materials, from stainless steel to acrylic, opening doors to diverse manufacturing possibilities.

3. Speed and Efficiency

In a fast-paced world, time is of the essence. Tube laser cutting is incredibly efficient, reducing production times and labor costs significantly.

4. Minimal Material Distortion

Unlike traditional cutting methods that generate heat and can lead to material distortion, tube laser cutting produces minimal heat-affected zones, preserving the structural integrity of the material.

5. Customization

The flexibility of tube laser cutting allows for easy customization of designs and shapes, catering to the unique requirements of each project.

Industries Embracing the Tubular Revolution

Tube laser cutting technology has found its way into various industries, where it’s making a substantial impact on the manufacturing process.

Automotive

In the automotive sector, tube laser cutting is used for precision cutting of chassis components, exhaust systems, and even intricate interior designs, contributing to improved vehicle performance and aesthetics.

Aerospace

Aerospace engineers have harnessed tube laser cutting to create lightweight, yet robust structures for aircraft and spacecraft. This technology helps reduce fuel consumption and enhance overall efficiency.

Construction

Tube laser cutting has simplified the construction of complex structural components, from architectural frameworks to steel reinforcements, resulting in more resilient and aesthetically pleasing buildings.

Healthcare

Even the healthcare industry has benefited from tube laser cutting, with applications ranging from the production of medical devices to surgical instruments, all requiring precision and consistency.

Harnessing the Benefits of Tube Laser Cutting

Tube laser cutting can provide a range of advantages to a manufacturer, including:

Improved accuracy and precision

Tube laser cutting delivers unparalleled accuracy and precision, allowing manufacturers to create components with intricate shapes and details.

Reduced costs and labor

Due to its efficiency, tube laser cutting requires fewer setup steps and less labor in comparison to traditional machining methods, resulting in reduced costs and improved efficiency.

Elimination of expensive welds

Tube laser cutting eliminates the need for expensive welds and other labor-intensive processes, reducing costs and providing manufacturers with greater flexibility.

Unleashing Creative Possibilities with Tube Laser Cutting

Tube laser cutting can help manufacturers unleash previously unimaginable creative possibilities in component production. From intricate internal components to complex geometries, this cutting-edge technology can help to create components that stand out from the competition. By taking advantage of this groundbreaking technology, manufacturers can stay ahead of the competition and produce components that are both cost-effective and of superior quality.

Conclusion

Tube laser cutting is revolutionizing the way manufacturers approach component design and production. With its ability to accurately and quickly cut through a range of materials, tube laser cutting technology can help manufacturers unlock new levels of efficiency and accuracy in their CNC machining operations. Whether it’s producing intricate and complex components with unprecedented precision or eliminating expensive labor-intensive processes, tube laser cutting technology can help to unleash countless creative possibilities.