What is a laser cutting machine?

A laser cutting machine is a device that uses a laser to cut materials. The laser beam is generated by a laser source, which is then focused into a small, intense beam by an optical system. This beam is then directed at the material to be cut, and the material is vaporized or burned away by the heat of the laser beam.

Laser cutting machines are used in a variety of industries, including automotive manufacturing, aerospace engineering, and electronics manufacturing. They are also used in hobbyist applications such as model making and engraving. Laser cutting machines can cut a variety of materials, including metals, plastics, glass, and wood.

Component of a Laser Cutting Machine

Laser System

Laser cutting machines have two main components: the laser generator and the laser head. The laser generator creates a high-powered beam of light that is then directed into the laser head. The laser head contains a series of mirrors that focus the beam of light onto the material that is being cut.

The laser generator is the most important component of a laser cutting machine. It produces a powerful beam of light that is focused into the laser head. Without a properly functioning laser generator, the machine will not be able to produce a clean cut.

The second important component of a laser cutting machine is the laser head. The laser head contains a series of mirrors that focus the beam of light onto the material that is being cut. These mirrors must be aligned correctly in order to produce a clean, straight cut.

Servo System

A servo system is an essential component of a laser cutting machine. It consists of three main parts: a motor, a feedback device, and a controller. The servo system controls the movement of the laser beam to cut materials accurately.

The motor in the servo system provides the power to move the laser beam. The feedback device helps the servo system to know the position of the laser beam. The controller tells the servo system how fast or slow to move the laser beam.

The servo system is an important part of a laser cutting machine because it ensures that materials are cut accurately. If any one of these three parts is not working correctly, it can result in inaccurate cuts.

CNC System

The CNC system is responsible for controlling the motion of the laser head and directing it along the desired cutting path. The majority of modern laser cutting machines use an X-Y table design, which allows for accurate positioning of the material being cut. Some more advanced CNC systems also have the ability to tilting or rotating the laser head, which gives them even more flexibility in terms of cutting paths.

Material handling system

A material handling system is a key component of any laser cutting machine. It ensures that the correct material is being cut, and that it is being cut accurately. Without a material handling system, the laser cutting machine would not be able to function properly.

There are many different types of material handling systems available on the market today. Some of the most popular options include conveyor belt systems, gantry systems, and track systems etc. Each type of system has its own set of benefits and drawbacks.

Power Supply

There are two types of power supplies used in laser cutting machines: direct current (DC) and alternating current (AC). DC power supplies are more commonly used in lower-power lasers, while AC power supplies are typically used in higher-power lasers. The type of power supply you need will depend on the specific requirements of your application.

Optics System

Another important component of a laser cutting machine is the optics system. This system includes the mirror, lens, and other optical elements that focus and direct the laser beam. The optics system must be carefully aligned to ensure that the laser beam is properly focused and directed onto the workpiece.

Cooling Element

The cooling element helps to keep the laser beam focused and stable, as well as prevent overheating of the machine. Without a properly functioning cooling element, the laser cutting machine would be significantly less effective and could even be damaged.

Gas Storage Reservoir

The gas storage reservoir is typically made out of stainless steel or another type of metal. It is important that the reservoir is made out of a material that can withstand high temperatures and pressures. The reservoir must also be able to hold a large amount of gas in order to create a powerful laser beam.

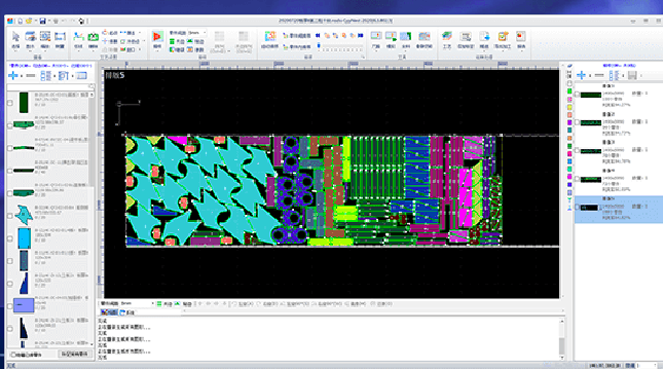

Laser Cutting Machine’s Software

the software is used to create designs that can be cut by the machine.

How does a laser cutting machine work?

A laser cutting machine uses a powerful laser to cut through materials. The laser is directed through a lens or mirror system that focuses the light onto a small area. This high-powered focused light then melts, burns, vaporizes, or vaporizes the material it is cutting.

Laser cutting machines are used in a variety of industries for cutting metals, plastics, wood, and glass. They are commonly used in the automotive and aerospace industries. Laser cutting machines can cut intricate shapes and designs out of materials quickly and accurately.

Usage of laser cutting machine

Laser cutting machines have become increasingly popular in a variety of industries for their versatility, speed, and accuracy. Here are some of the most common uses for laser cutting machines:

1. Cutting sheet metal: Laser cutting machines can quickly and easily cut through sheet metal, making them ideal for fabrication shops.

2. Engraving: Laser engraving is a popular way to personalize items or create detailed designs.

3. Marking: Laser marking is an efficient way to mark products with barcodes, serial numbers, or other information.

4. Cutting plastics: Lasers can be used to cut through a variety of plastics, making them ideal for prototyping or creating custom parts.

Conclusion

In conclusion, a laser cutting machine has four main components: the laser, the controller, the cutting head, and the bed. The laser is the key component of the machine, as it is responsible for generating the high-powered beam that does the cutting. The controller manages the movement of the cutting head and the bed, while also regulating the power of the laser. The cutting head houses the optics that focus the laser beam onto the material being cut.